Three-engine double-propeller diesel-gas-electric hybrid ship power system

A ship and power technology, applied in the field of ship hybrid power system, can solve the problems of battery capacity limitation of endurance, speed acceleration and self-control that cannot achieve high performance, achieve excellent dynamic response, improve reliability and applicability, power A wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in more detail below in conjunction with accompanying drawing example:

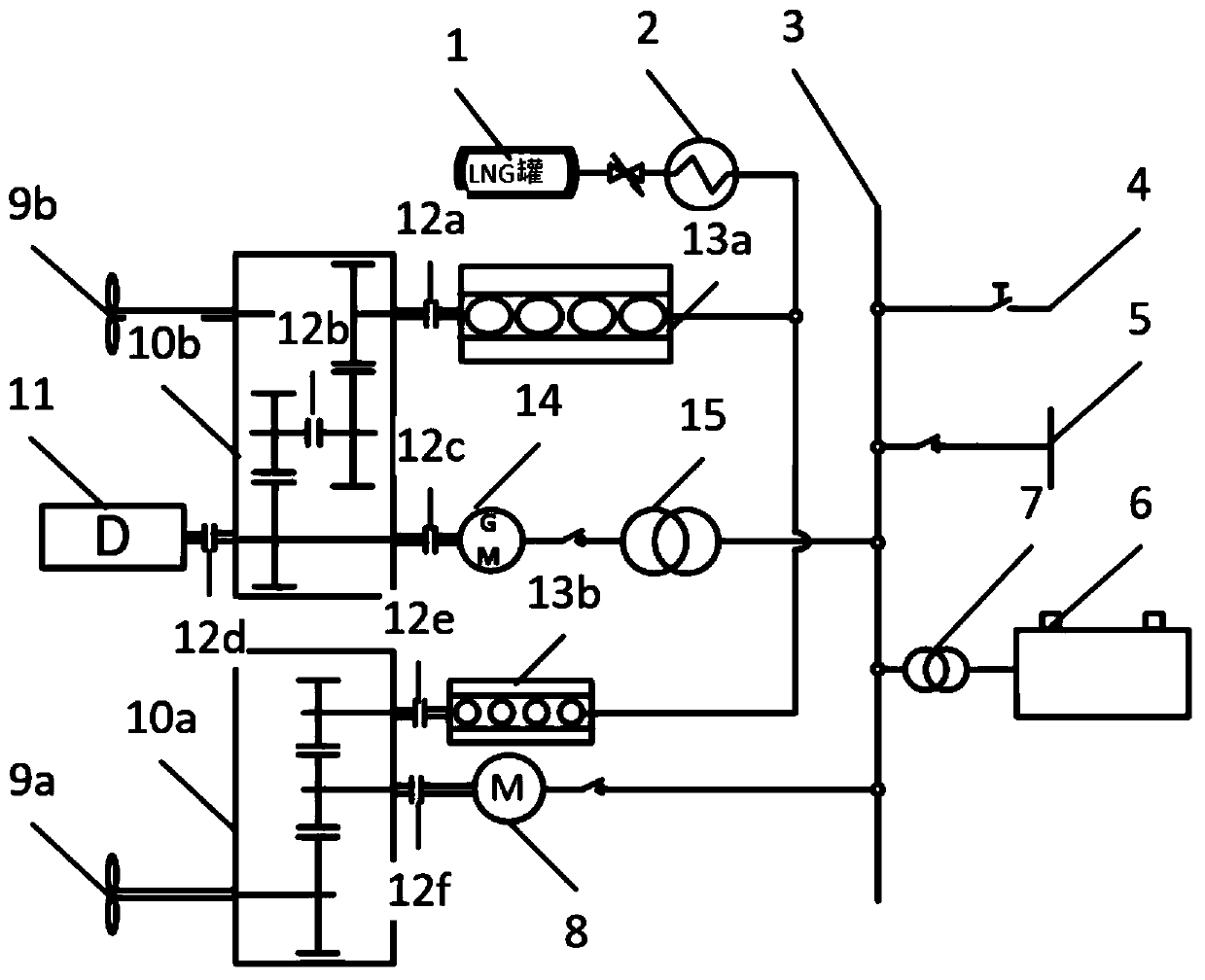

[0033] combine figure 1 , the present invention is a three-engine dual-blade diesel-gas-electric hybrid ship power system, including LNG tank 1, gasification heat exchanger 2, ship power grid 3, shore power device 4, ship load 5, battery 6, battery power conversion device 7. Electric motor 8, propeller 9a, 9b gearbox 10a, 10b, diesel engine 11, clutch 12a, 12b, 12, c12, 12d, 12e, 12f gas engine 13a, 13b reversible motor 14, reversible motor transformer 15. Its connection relationship is: the output end of the gas machine 13a is connected with the input end of the gear box 10b through the clutches 12a, 12d, the reversible motor 14 is connected with the gear box 10b through the clutch 12c, the propeller 9b is connected with the output end of the gear box 10b; the gas machine 13b, The electric motor 8 is connected with the input end of the gear box 10a, and the prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com