Real-time monitoring, early warning and dust removing system and method for corrosion foil surface

A technology for real-time monitoring and corrosion of foil, applied in transportation and packaging, coiling strips, thin material processing, etc., can solve the problem of no real-time monitoring system for aluminum foil surface, reduce production efficiency, return loss, etc., to achieve real-time testing The effect of collecting and cleaning work, efficient and accurate, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

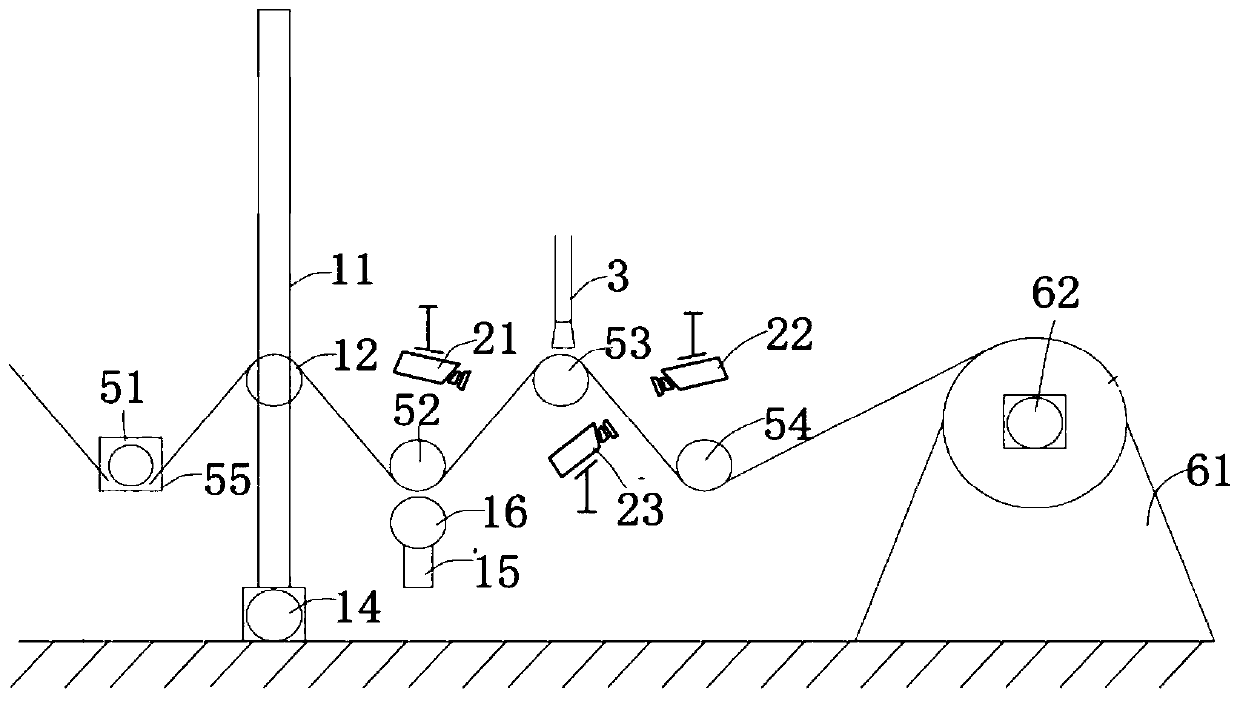

[0037] Embodiment 1 A system and method for real-time monitoring, early warning and dust removal of corroded foil surface

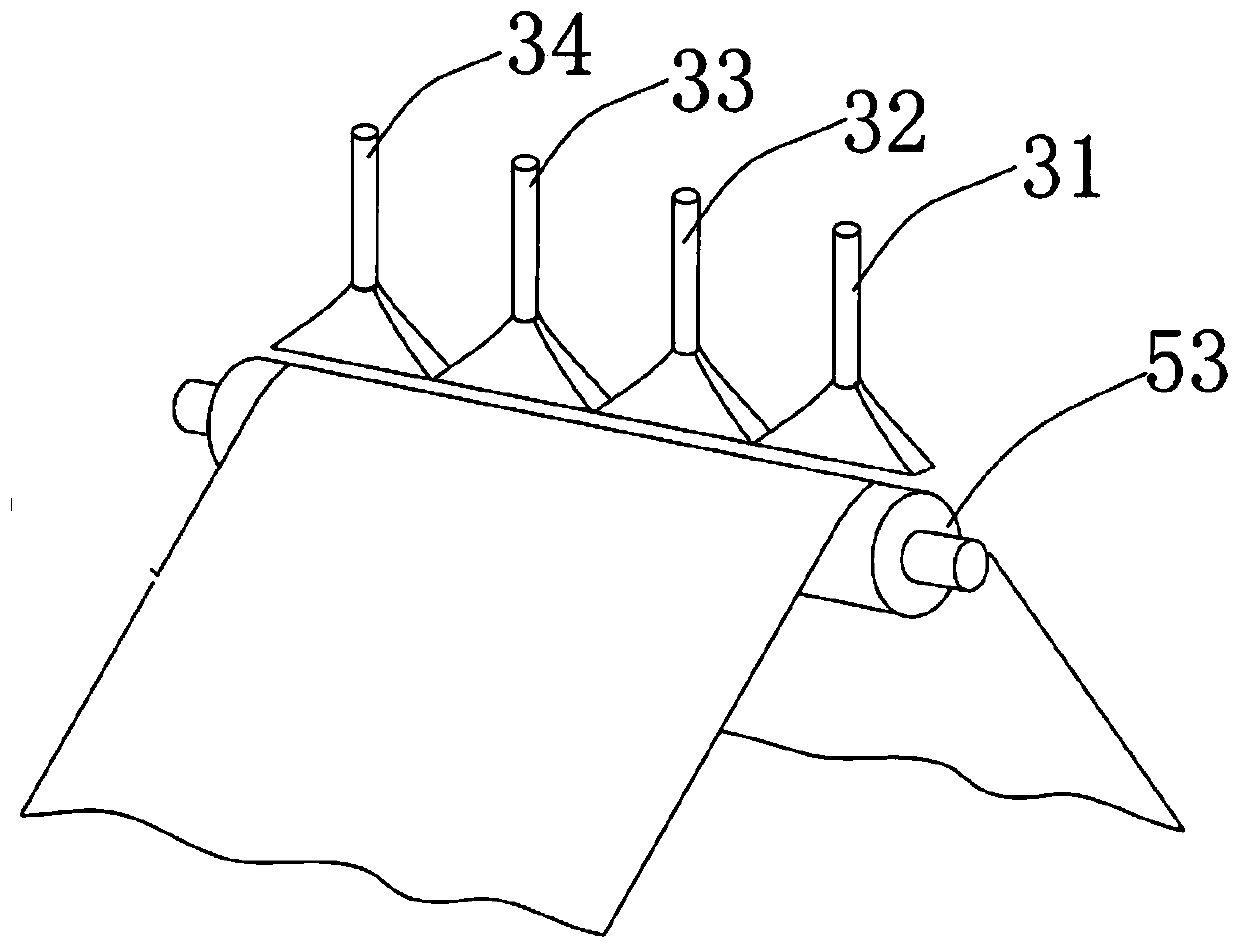

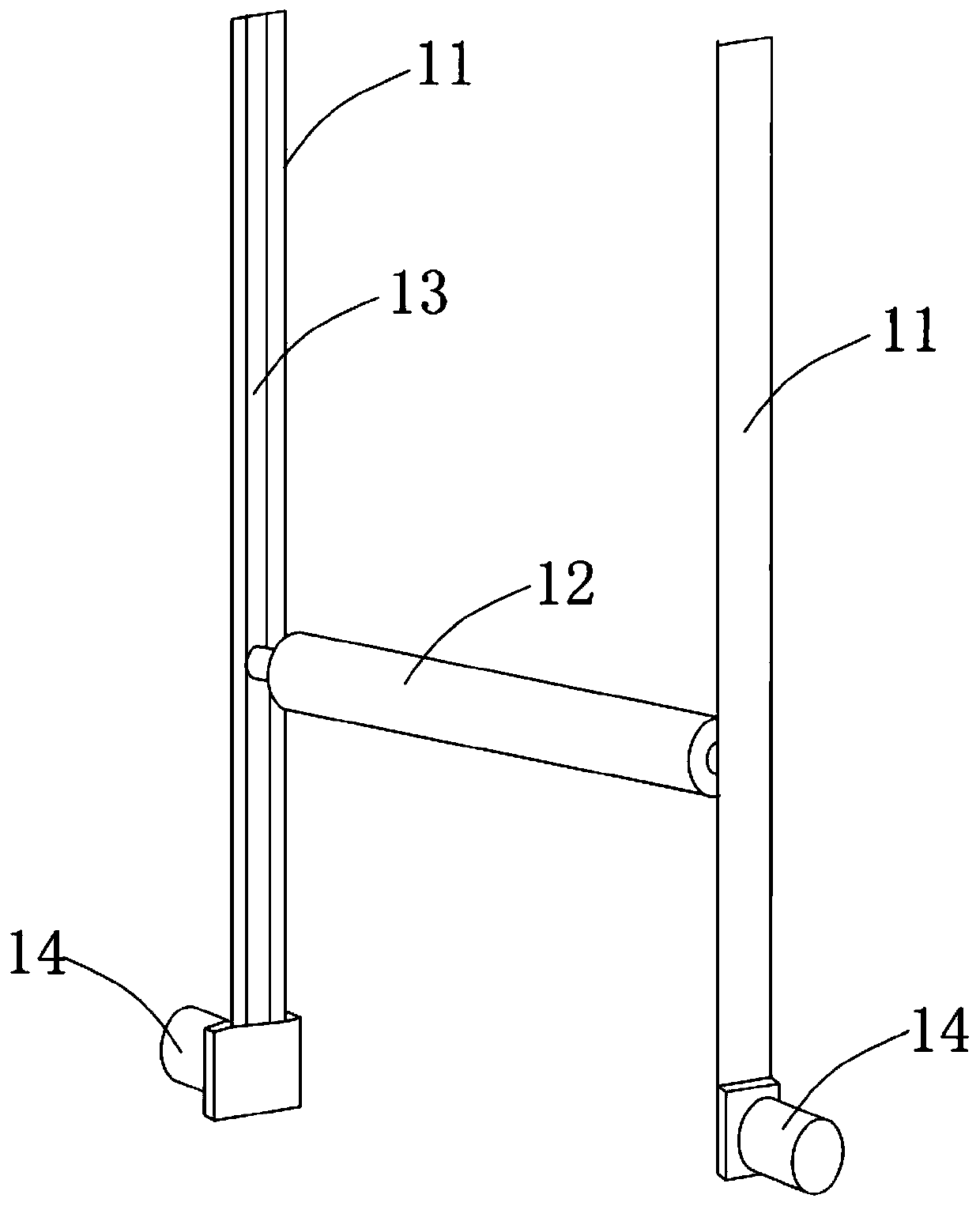

[0038] Such as figure 1 As shown, a system for real-time monitoring, early warning and dust removal on the surface of corroded foil includes a transmission roller mechanism, a winding mechanism and an alarm device 7; a buffer mechanism 1, an image capture component 2 and a dust removal mechanism are arranged between the transmission roller mechanism and the winding mechanism device 3. This transmission roller mechanism comprises first transmission roller 51, second transmission roller 52, the 3rd transmission roller 53, the 4th transmission roller 54 and transmission motor 55; Between; the lifting drive roller 12, the first drive roller 51, the second drive roller 52, the third drive roller 53 and the fourth drive roller 54 are all arranged in parallel to each other, the first drive roller 51, the second drive roller 52, the fourth drive roller The hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com