A kind of preparation method of laser cladding material and laser cladding coating

A laser cladding and coating technology, applied in the field of mold manufacturing, can solve the problems of poor self-fluxing high temperature performance of Fe-based laser cladding materials, low production cost, poor bonding between coating and substrate, etc., and achieves significant engineering application prospects , improve service life, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In terms of quality score:

[0039] Transition layer material: C: 0.1%, Si: 0.5%, Mn: 0.3%, Cr: 6%, Mo: 2%, V: 0.2%, and the balance is Fe.

[0040] Surface strengthening layer material: C: 0.5%, Si: 0.2%, Mn: 0.3%, Cr: 8%, Mo: 4%, V: 0.3%, and the balance is Fe.

Embodiment 2

[0042] In terms of quality score:

[0043]Transition layer material: C: 0.3%, Si: 0.75%, Mn: 0.35%, Cr: 7%, Mo: 3%, V: 0.25%, and the balance is Fe.

[0044] Surface strengthening layer material: C: 0.7%, Si: 0.5%, Mn: 0.35%, Cr: 8%, Mo: 4.5%, V: 0.4%, and the balance is Fe.

Embodiment 3

[0046] In terms of quality score:

[0047] Transition layer material: C: 0.5%, Si: 1%, Mn: 0.4%, Cr: 8%, Mo: 4%, V: 0.3%, and the balance is Fe.

[0048] Surface strengthening layer material: C: 0.85%, Si: 0.5%, Mn: 0.4%, Cr: 10%, Mo: 5%, V: 0.5%, and the balance is Fe.

[0049] 2. Preparation of laser cladding coating

[0050] 45 steel plates were taken, and the laser cladding materials provided in Examples 1-3 were respectively clad on the steel plates. The specific coating preparation steps are as follows:

[0051] 1) Pre-treat the surface of the cold stamping die to be treated; first use an angle grinder to remove surface rust, then use industrial alcohol to clean, and finally perform synchronous laser cladding after the alcohol is completely volatilized.

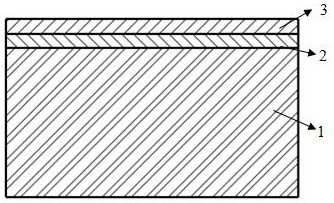

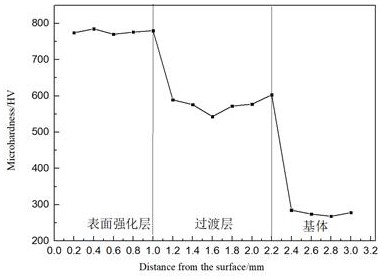

[0052] 2) Cladding the transition layer material on the surface of the pretreated cold stamping die by using fiber laser and synchronous powder feeding device to form a transition layer closely combined with the cold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com