Parylene color film coating process and film coating device

A coating device, the technology of Parylene, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems that the coating material is difficult to detect, and the product cannot be directly observed with the naked eye, so as to solve the problems that are difficult to detect, Low cost, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0040] The parylene color coating process provided by the present embodiment comprises the following steps:

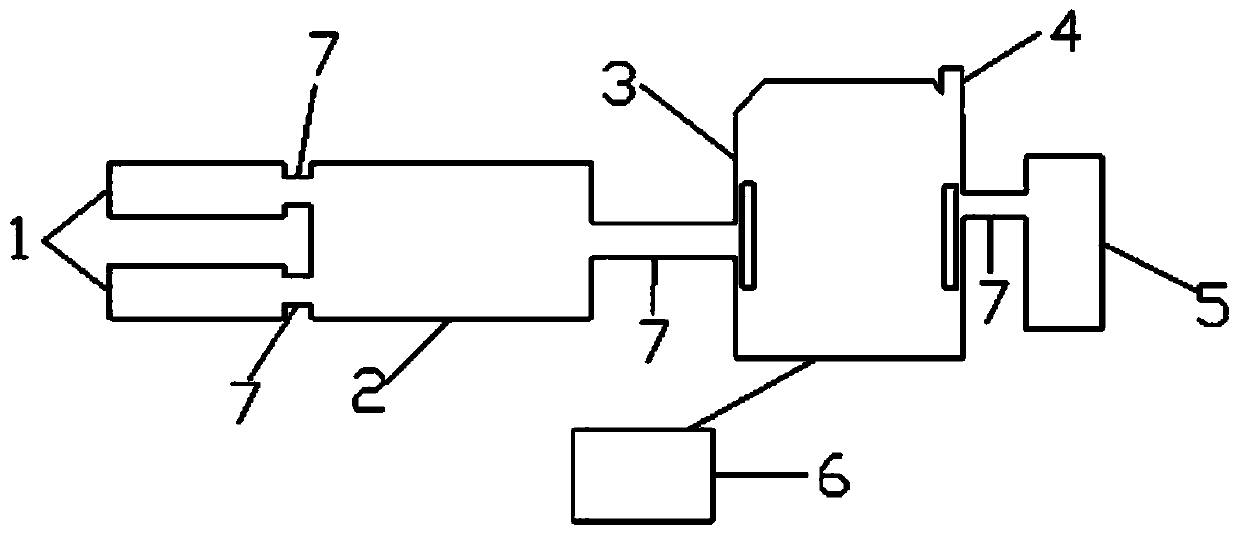

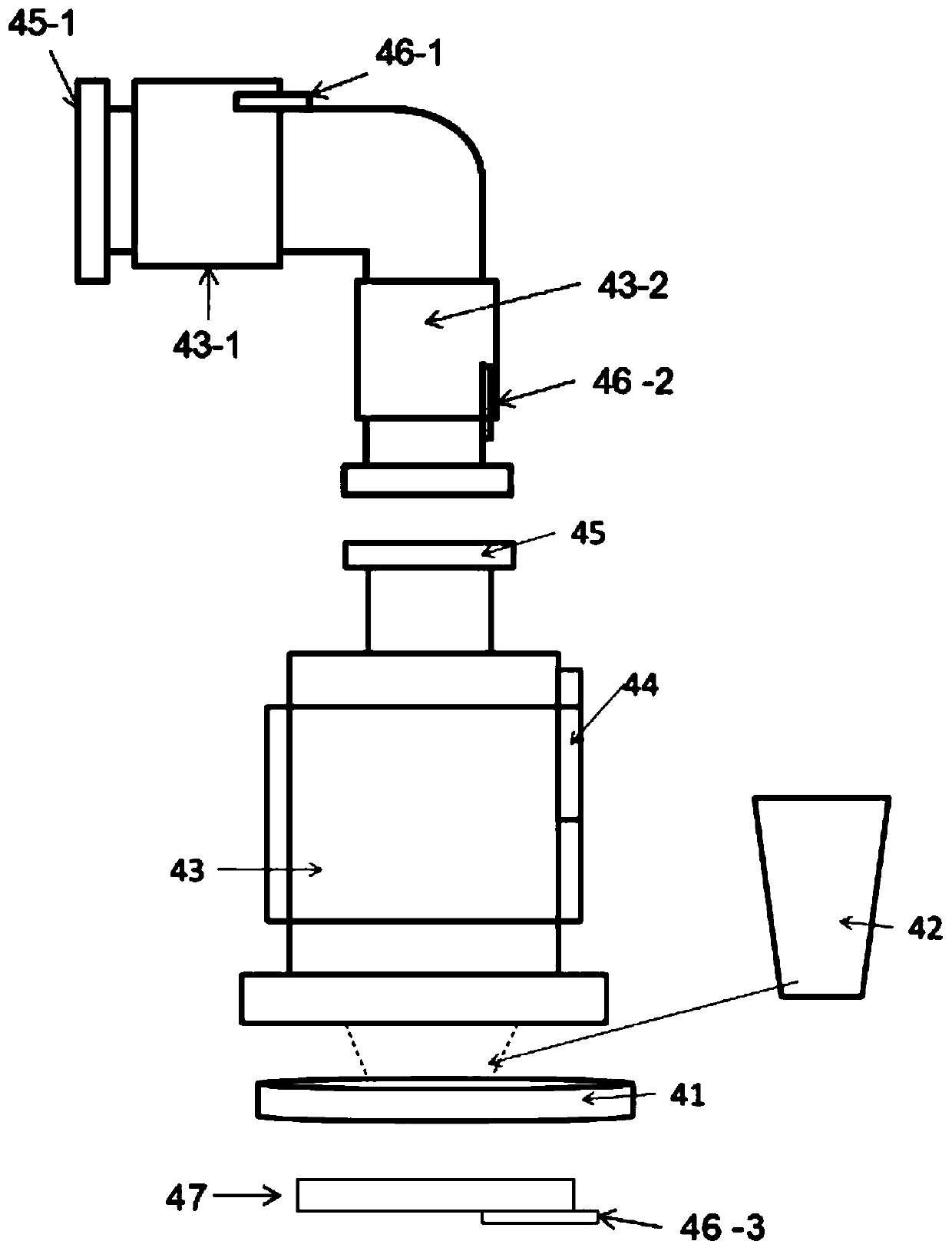

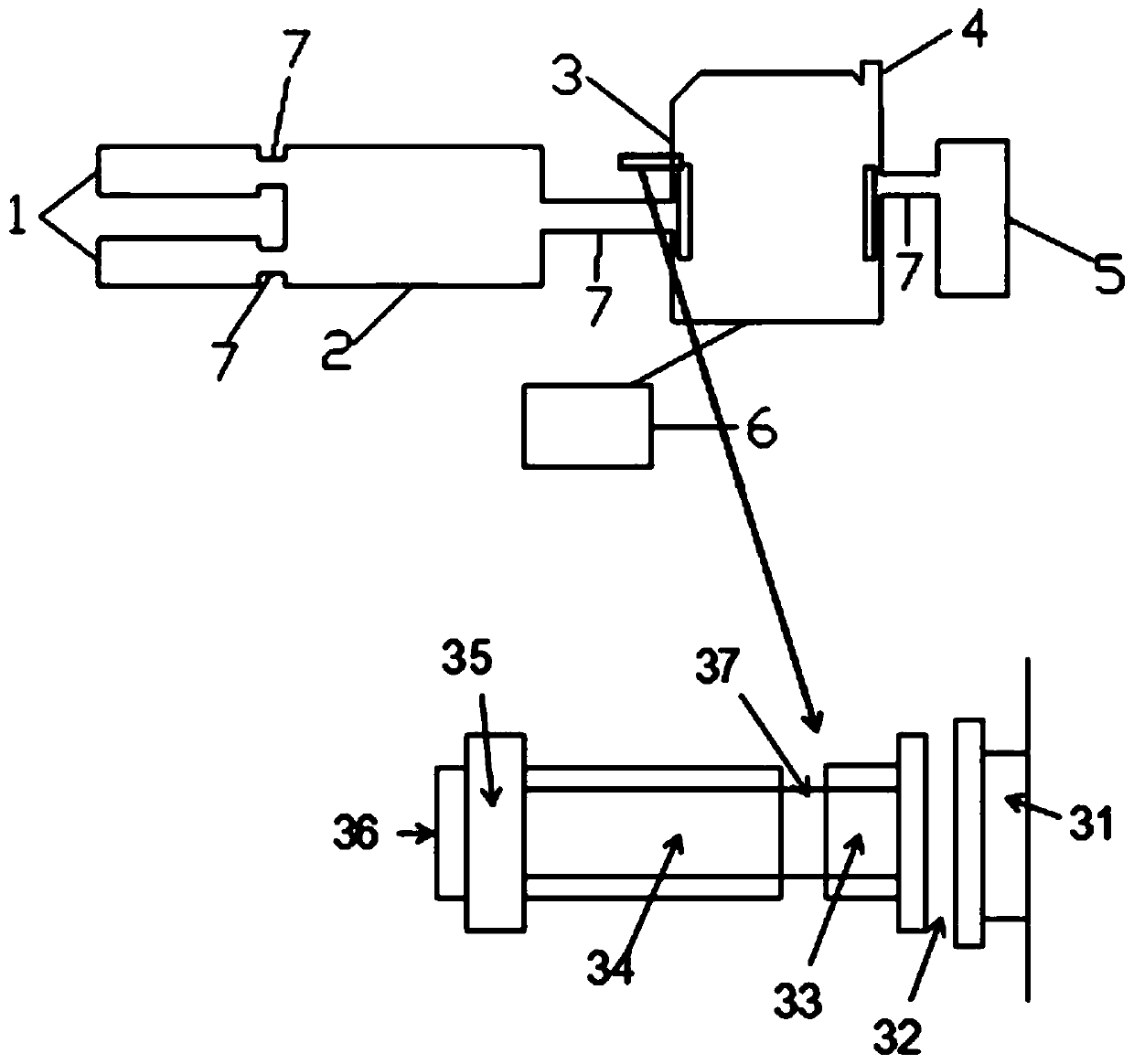

[0041] Step 1: Put the colored dye powder into the sublimation cup, seal the sealing ring, fix the heating ring on the sublimation cup, connect the sublimation cup with the vacuum deposition chamber through the connecting ring, and fix it, and connect the vacuum deposition chamber and the heating ring connected to the heating controller;

[0042] Step 2: sealing the vacuum deposition chamber and pumping it to a vacuum through a vacuum system;

[0043] Step 3: using a cooling controller to control the temperature of the vacuum deposition chamber area betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com