thermostat seat

A technology of thermostat and sealing surface, applied in the direction of machine/engine, engine cooling, mechanical equipment, etc., can solve the problems of high scrap rate, easy breakage, high cost, improve casting yield, reduce fracture failure, Simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

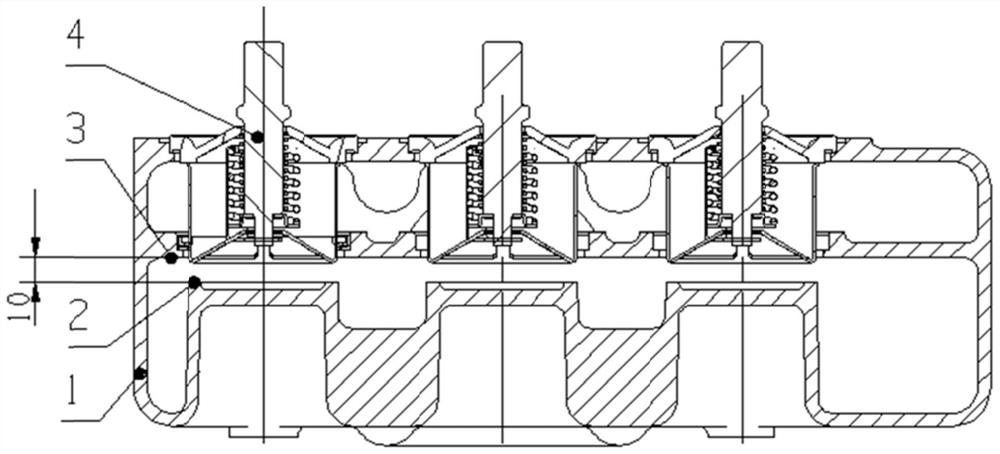

[0027] Such as figure 1 As shown, the three thermostats 4 are installed on the thermostat seat 1. Generally, the lift of the thermostat 4 is ≧10mm. In this way, the sealing surface 2 of the thermostat seat and the step surface 3 of the thermostat seat are required. The distance between them is ≦10 mm.

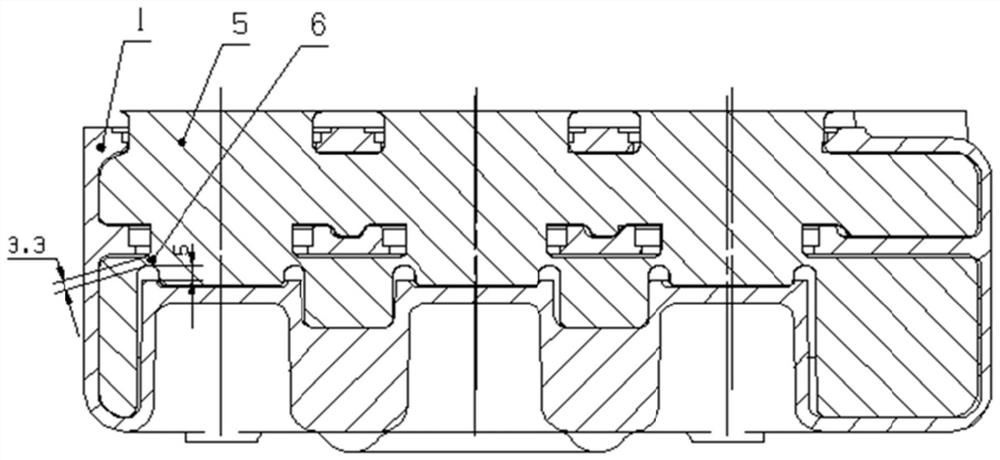

[0028] Such as figure 2 As shown, the schematic diagram of the assembly of the thermostat seat and the casting sand core. The sealing surface 2 of the thermostat seat and the step surface are both processed surfaces, and a machining allowance of 3 mm to 5 mm needs to be reserved at this position of the thermostat seat 1 blank. Therefore, the thickness of the thin-walled area 6 of the casting sand core of the thermostat seat 1 is only 3.3 mm, and the part is easy to break when the sand core is assembled or poured, and casting defects are prone to occur, resulting in high scrap rate and high cost.

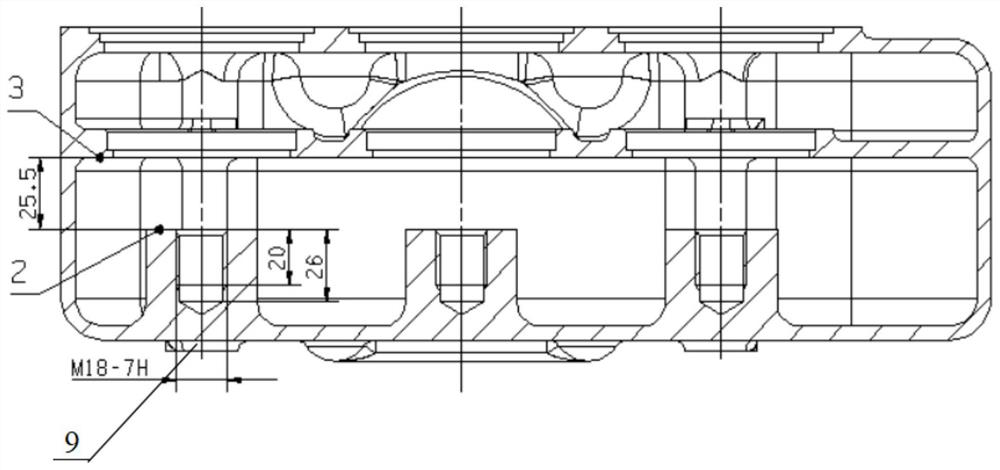

[0029] Such as image 3 , the thermostat seat of the present invention incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com