Benthal deposit collecting system and method

A collection system and sediment technology, applied in the direction of sampling device, test sample preparation, etc., can solve the problems of complicated operation of the collection device, low sampling efficiency, inability to use deep water sampling, etc., and achieve low impact on the underwater environment, convenient operation, small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

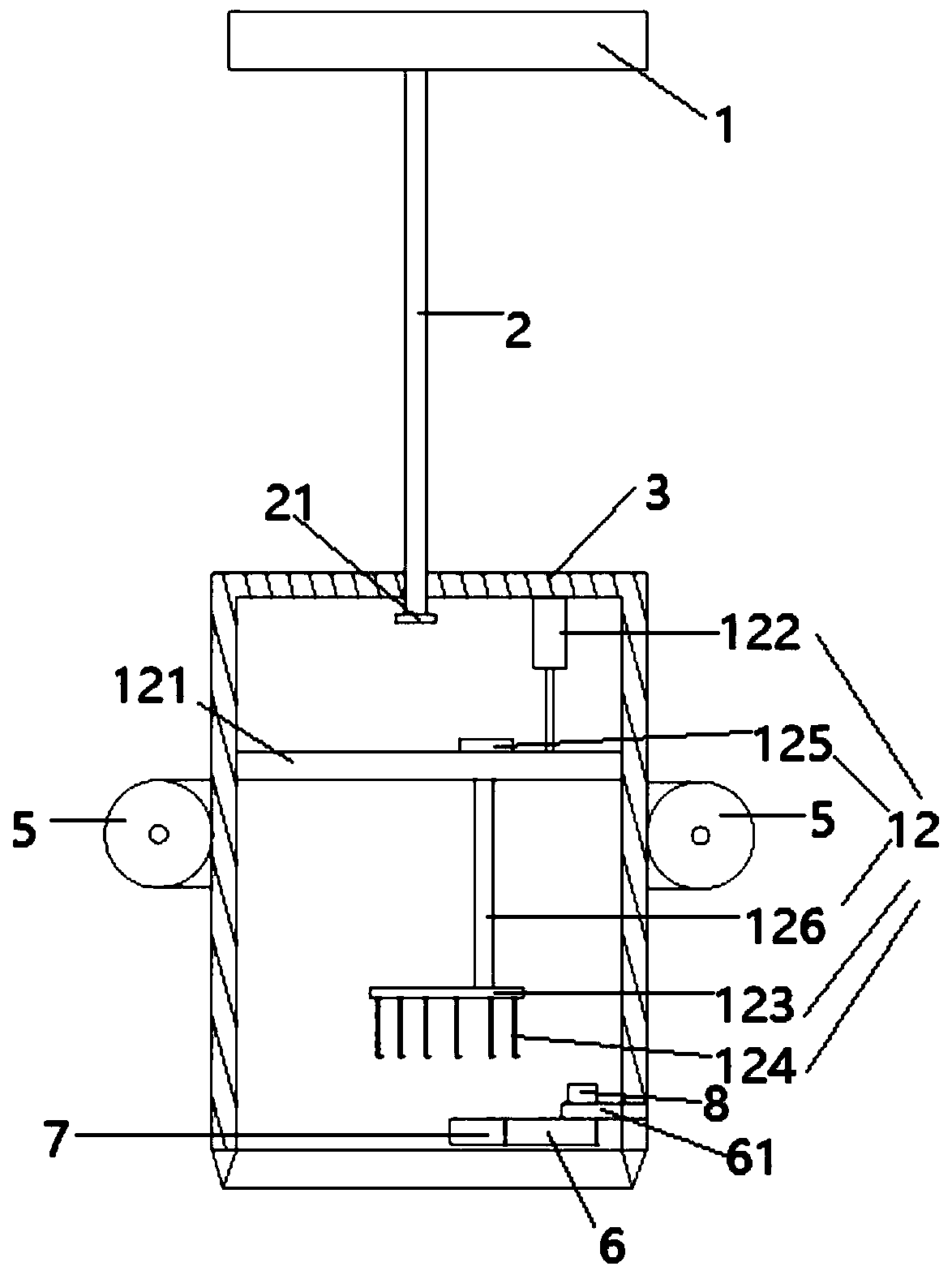

[0041] Such as figure 1 , Figure 5 The shown embodiment is a kind of underwater sediment collecting system, comprises the platform 1 that protrudes out of the ship, is arranged on the column 2 on the platform, and the column 3 that the lower end opening of the column is rotatably connected, is located at the column outer peripheral surface 3 ultrasonic distance measuring sensors 4, 4 drainage tubes 5 arranged on the vertical cylinder along the circumferential direction of the outer peripheral surface of the vertical cylinder, and an arc-shaped box body 6 arranged in the lower part of the vertical cylinder, fixed with the arc-shaped box body Connected arc knife 7; the arc box body is connected with the box body motor 8 fixed on the lower part of the inner wall of the vertical cylinder through the connector 61, and the arc box body is provided with a gauze mechanism 11, and the arc knife is connected with the gauze mechanism , the gauze fixing mechanism 12 is provided in the v...

Embodiment 2

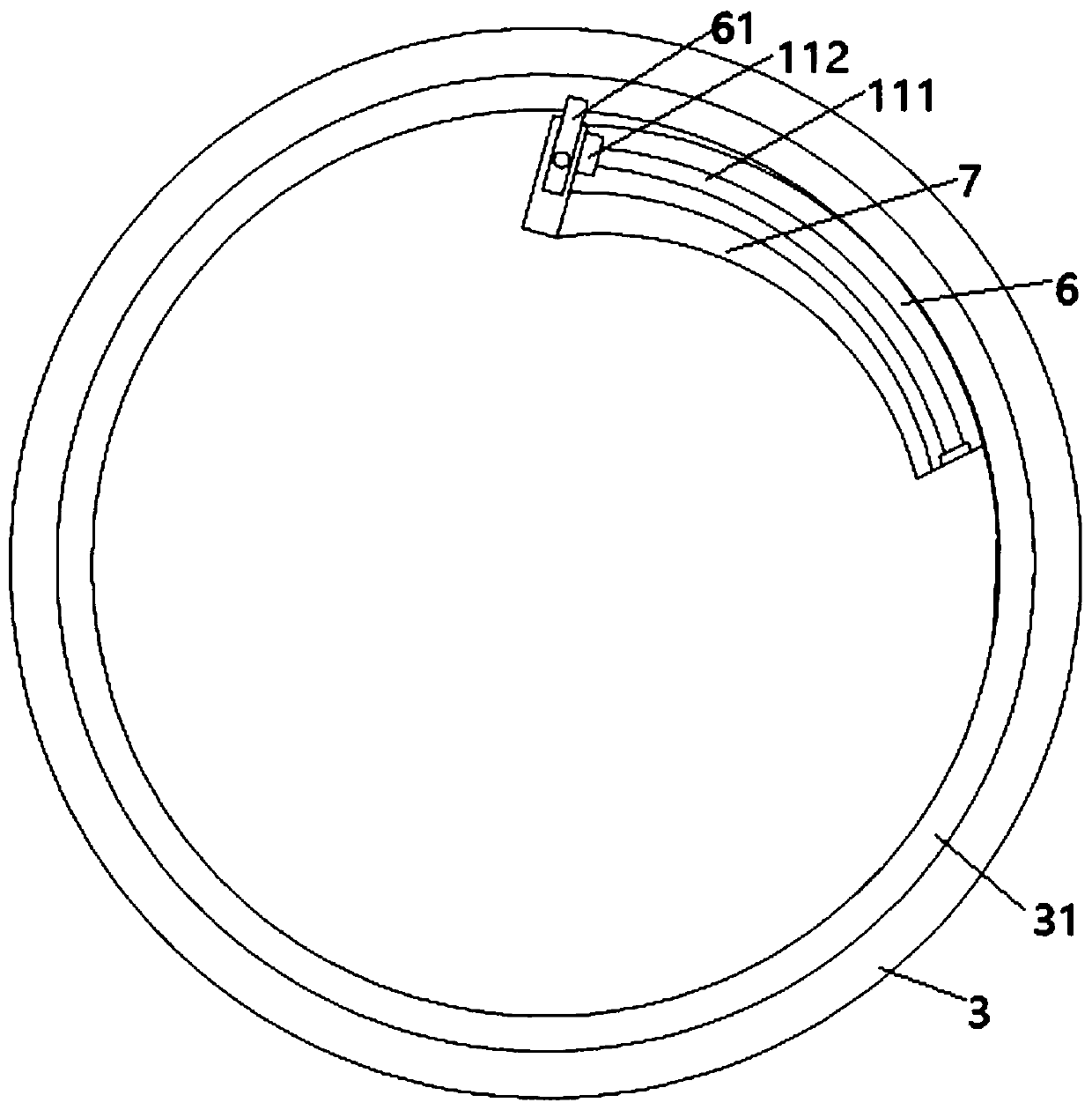

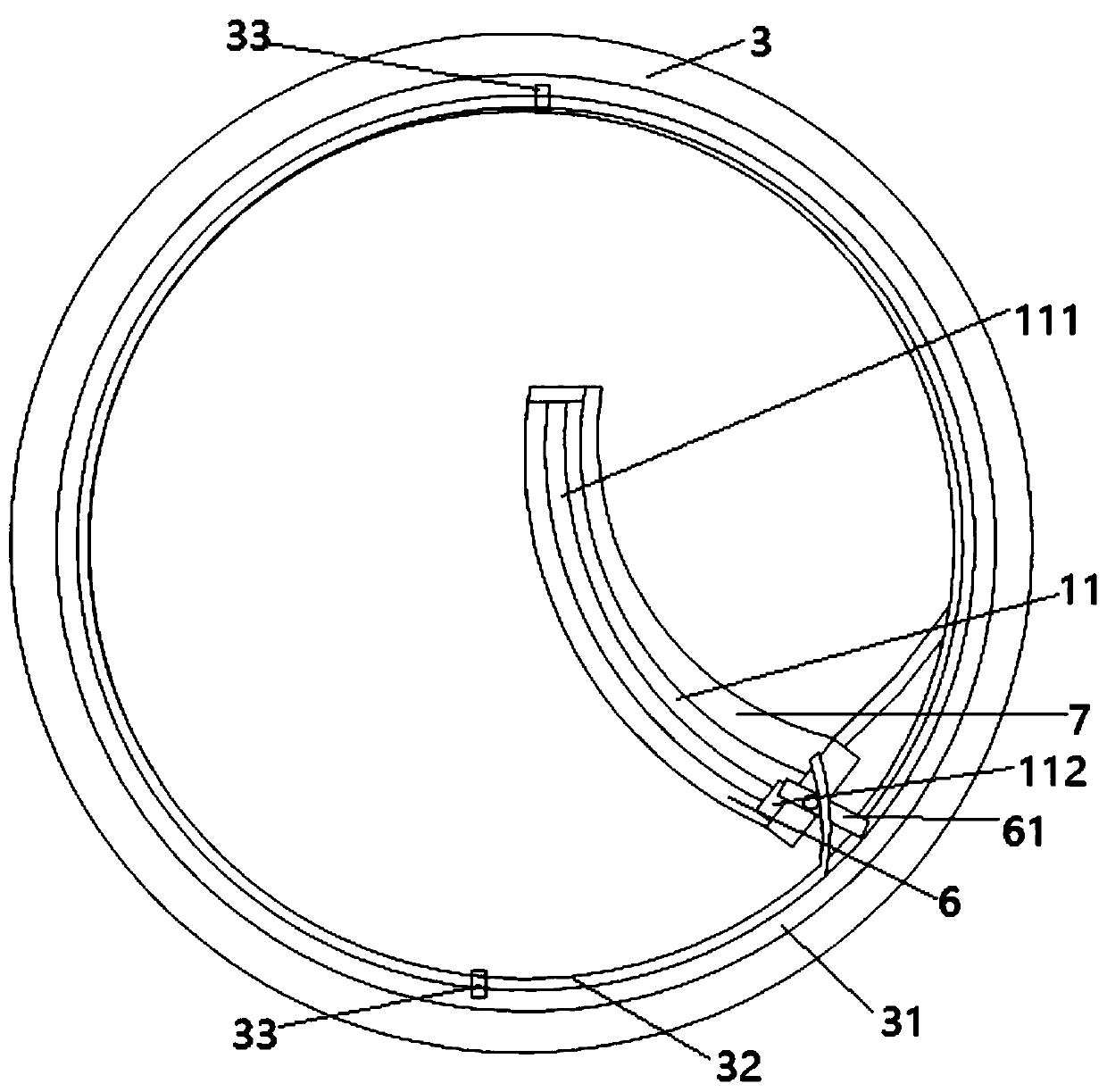

[0054] Embodiment 2 includes all structures and methods of Embodiment 1, such as figure 1 , figure 2 As shown, the gauze mechanism of embodiment 2 includes a flexible shaft 111 arranged in an arc-shaped box body, a gauze wound on the flexible shaft, and an auxiliary motor 112 for driving the flexible shaft to rotate; one end of the flexible shaft passes through the bearing and the arc Shaped box connection, the other end of the flexible shaft is connected to the auxiliary motor, such as Figure 5 As shown, the auxiliary motor is electrically connected to the controller; an elastic rope is arranged on the gauze near the axis of the vertical cylinder, and the gauze is connected with the arc knife;

[0055] Such as Figure 4 As shown, it also includes an annular groove 31 located at the lower part of the inner side wall of the vertical cylinder, two guide grooves located on the upper side wall and the lower side wall in the annular groove, and the annular groove is provided wi...

Embodiment 3

[0059] Embodiment 3 includes all structure and method parts of embodiment 1, as figure 1 , Figure 5 As shown, the gauze fixing mechanism of Embodiment 3 includes a bracket 121 arranged in the vertical cylinder, a cylinder 122 arranged at the top of the vertical cylinder, a horizontal plate 123 connected with the telescopic rod of the cylinder, and a horizontal plate 123 arranged on the lower surface of the horizontal plate. 10 hooks 124, each hook is arranged in a circular shape, the support is provided with a rotating motor 125, the rotating motor is connected with the horizontal plate through the vertical bar 126, and the cylinder and the rotating motor are electrically connected with the controller; The avoidance hole of the baffle.

[0060] Steps (6-5) are replaced by the following steps:

[0061] The controller controls the cylinder to drive the bracket to move down until each hook contacts the gauze under the sediment layer, and the controller controls the rotating mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com