Automatic brushing device for tree heat-retention coating

A coating and automatic technology, applied in the field of gardening, can solve the problems of difficult to maintain uniform application, harmful to health, and application effect depends on the effect of improving tree brushing efficiency, reducing direct contact and brushing evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

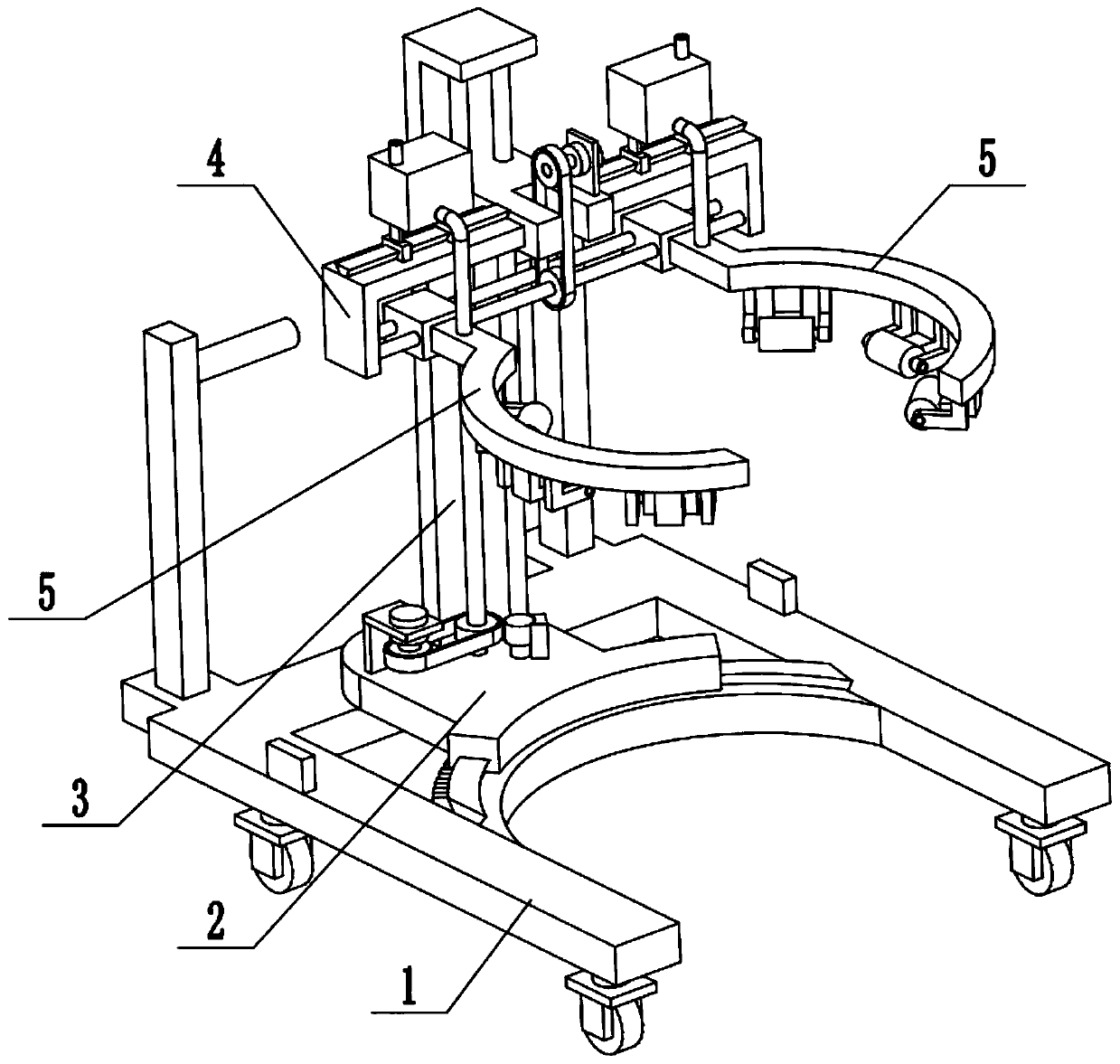

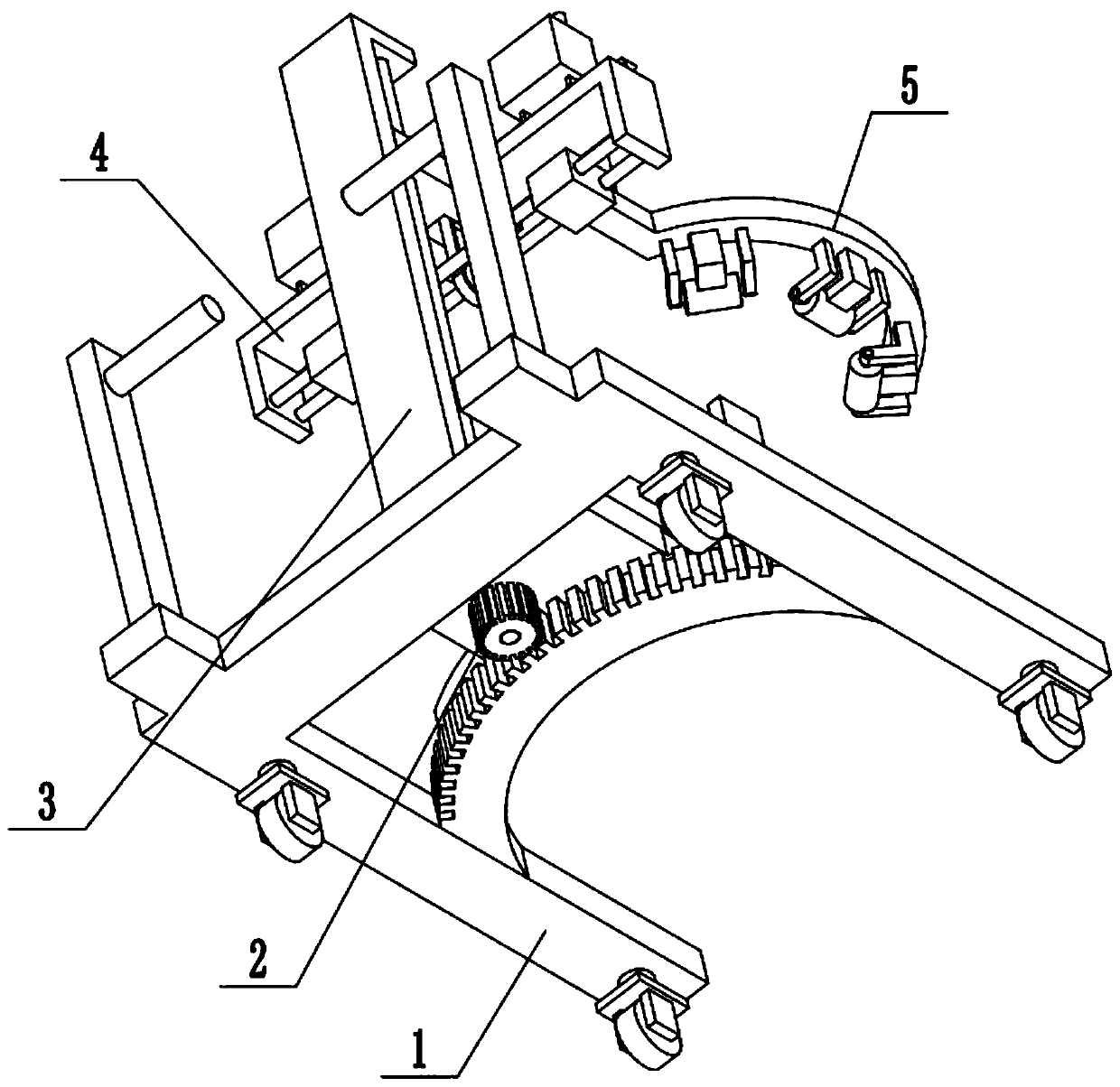

[0026] Combine below Figure 1-8 Describe this embodiment, an automatic brushing device for thermal insulation coatings for trees, including a movable base assembly 1, a rotating seat assembly 2, a reciprocating brushing assembly 3, a diameter adjusting assembly 4 and a brush roller assembly 5, the rotating seat assembly 2 is connected to the movable base assembly 1 by sliding fit, the reciprocating brushing assembly 3 is fixedly connected to the rotating seat assembly 2, the diameter adjustment assembly 4 is connected to the reciprocating brushing assembly 3 by sliding fit, and the diameter adjustment assembly 4 is connected to the On the reciprocating brushing assembly 3 , there are two brush roller assemblies 5 , and the two brush roller assemblies 5 are symmetrically arranged at both ends of the diameter adjustment assembly 4 . When the present invention is in use, after the diameter adjustment assembly 4 is connected to the power supply and started, the diameter adjustmen...

specific Embodiment approach 2

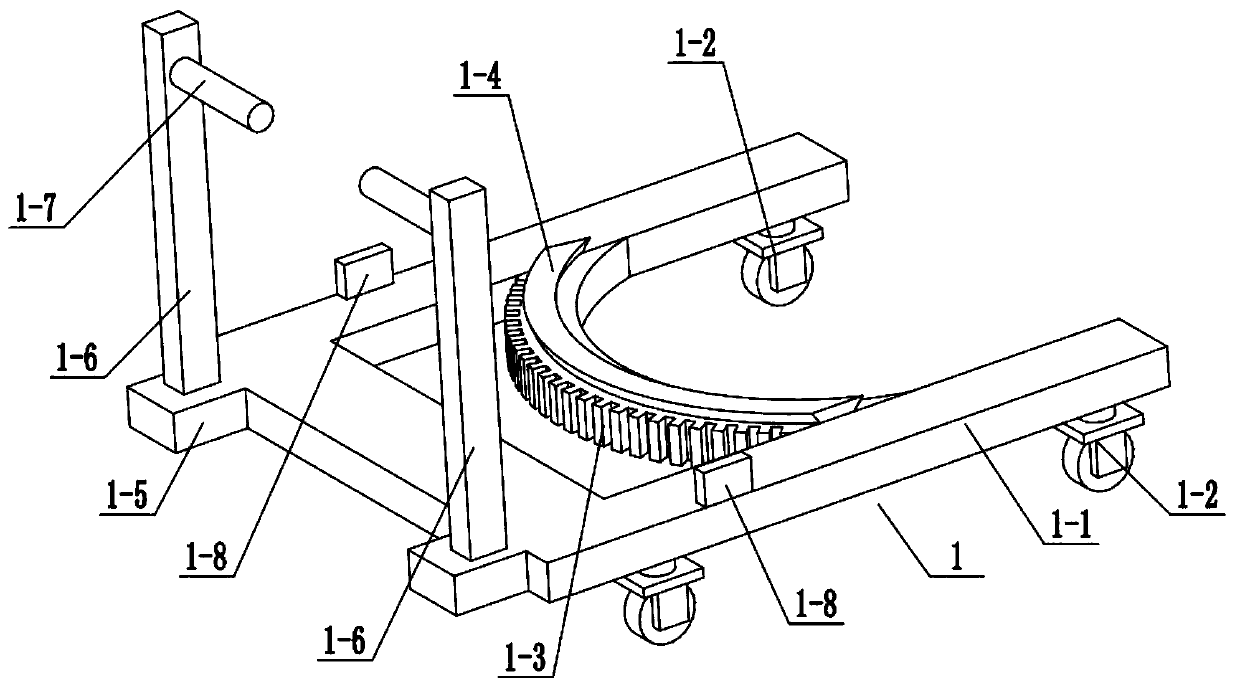

[0027] Combine below Figure 1-8To illustrate this embodiment, the movable base assembly 1 includes a door-shaped base 1-1, a roller 1-2, an arc-shaped rack 1-3, an arc-shaped trapezoidal bar 1-4, a fixed block 1-5, a support Rod 1-6 and push rod 1-7; the four corners of the bottom surface of the door-shaped base 1-1 are respectively rotated and connected to a roller 1-2, and the arc-shaped rack 1-3 is fixedly connected to the inner side of the door-shaped base 1-1. The curved trapezoidal bar 1-4 is fixedly connected to the curved rack 1-3, the rear end of the door-shaped base 1-1 is fixedly connected to two fixed blocks 1-5, and both fixed blocks 1-5 are fixedly connected A support rod 1-6 is fixedly connected to a push rod 1-7 on the two support rods 1-6. When the movable base assembly 1 is in use, the door-shaped base 1-1 can be pushed by holding two push rods 1-7, the four rollers 1-2 facilitate the movement of the device, and the two brush roller assemblies 5 When the d...

specific Embodiment approach 3

[0028] Combine below Figure 1-8 To illustrate this embodiment, the rotating seat assembly 2 includes an arc-shaped sliding seat 2-1, an angle-adjusting seat 2-2, an angle-adjusting motor 2-3, a transmission shaft 2-4, and an angle-adjusting gear 2-5; The rear end of the slide seat 2-1 is fixedly connected to the angle adjustment seat 2-2, and the angle adjustment seat 2-2 fits with the top surface of the door-shaped base 1-1; the bottom surface of the arc slide seat 2-1 is provided with Trapezoidal chute, arc-shaped sliding seat 2-1 is connected to the arc-shaped trapezoidal bar 1-4 through the sliding fit of the trapezoidal chute, the angle adjustment motor 2-3 is fixedly connected to the angle adjustment seat 2-2 through the motor frame, and the angle adjustment The output shaft of the motor 2-3 is connected to the transmission shaft 2-4 through a shaft coupling, the transmission shaft 2-4 is rotated and connected to the angle adjustment seat 2-2, and the lower end of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com