Cold continuous rolling mill starting control optimization method and device

A technology of cold tandem rolling mill and optimization method, which is applied in the direction of rolling force/roll gap control, etc., which can solve the problems of ineffective reduction of depreciation costs per ton of steel and production costs, failure of starting raw material plates, idle equipment of acid rolling mills, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

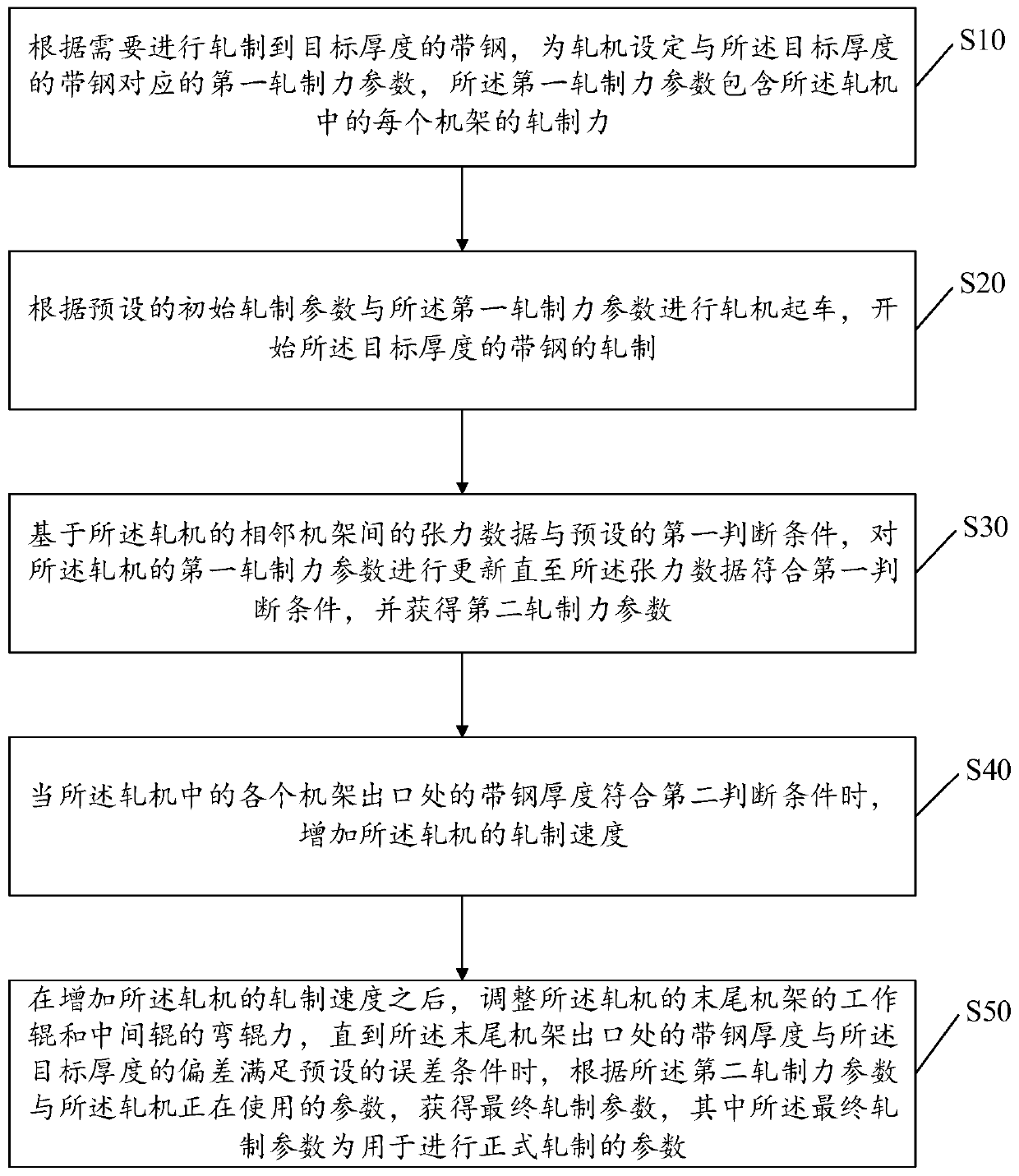

Method used

Image

Examples

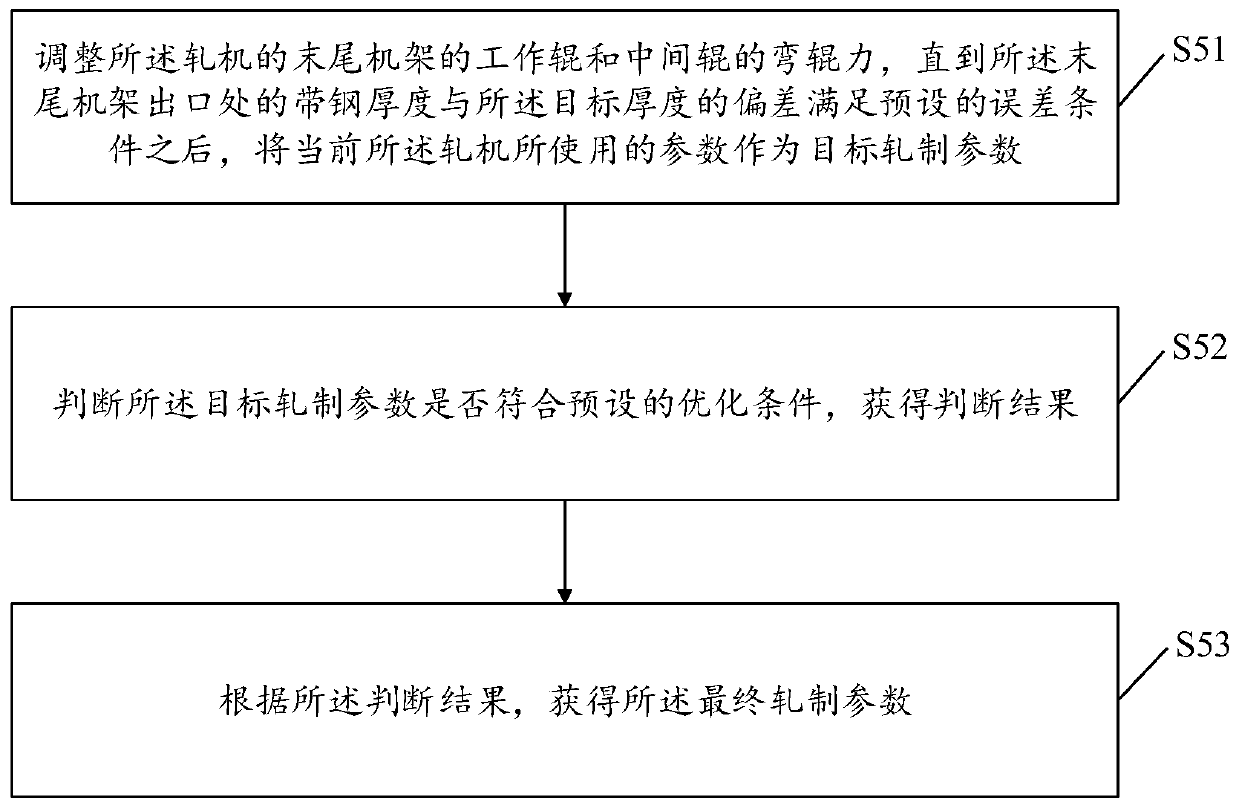

Embodiment approach

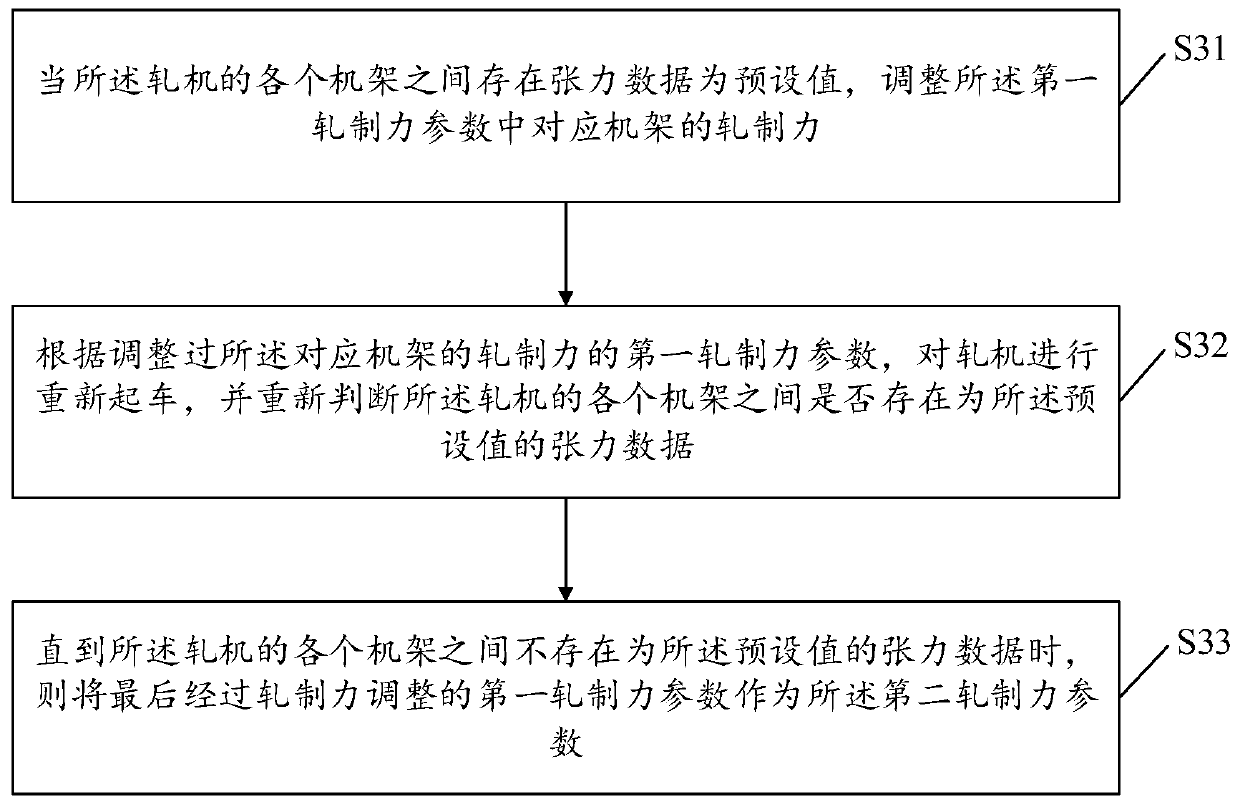

[0052] Specifically, see figure 2 , an implementation manner of step S30 is:

[0053] Step S31: When the tension data between each stand of the rolling mill is a preset value, adjust the rolling force of the corresponding stand in the first rolling force parameter. Wherein, the preset value indicates a smaller value of the tension data, or the preset value is zero, that is, the first preset condition is not met. At this time, the rolling mill can be stopped.

[0054] Step S32: Restart the rolling mill according to the first rolling force parameter that has adjusted the rolling force of the corresponding stand, and re-judge whether there is a preset value between each stand of the rolling mill tension data. Specifically, the way to adjust the first rolling force parameter can be to change the deformation resistance L value (the parameter range is 60-120) used to calculate the rolling force in the second stage, so as to correct the set rolling force of each stand , send the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com