High-strength and high-toughness 2XXX aluminum alloy forging production process

A high-strength, high-toughness, production process technology, applied in the field of aluminum alloy processing, can solve the problems of low fatigue life and poor corrosion resistance, and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

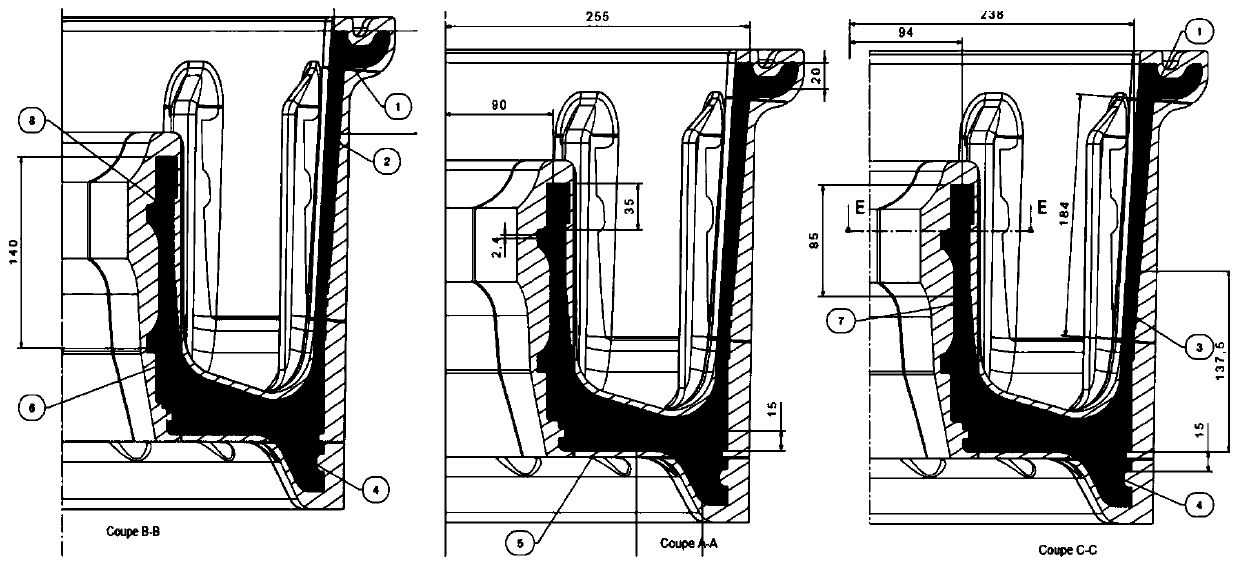

[0027] A high-strength and high-toughness 2XXX aluminum alloy forging production process is characterized in that the ingredients used for processing aluminum alloy ingots are sequentially smelted, double-stage homogenization treatment, extrusion billet forming, extrusion billet annealing, forging forming and rapid T6 heat treatment, processed into high-strength and high-toughness 2XXX aluminum alloy forgings;

[0028] Step 1, the smelting is to place the prepared aluminum alloy raw material in a smelting furnace to melt into liquid aluminum alloy, and melt and cast the liquid aluminum alloy into aluminum alloy ingot;

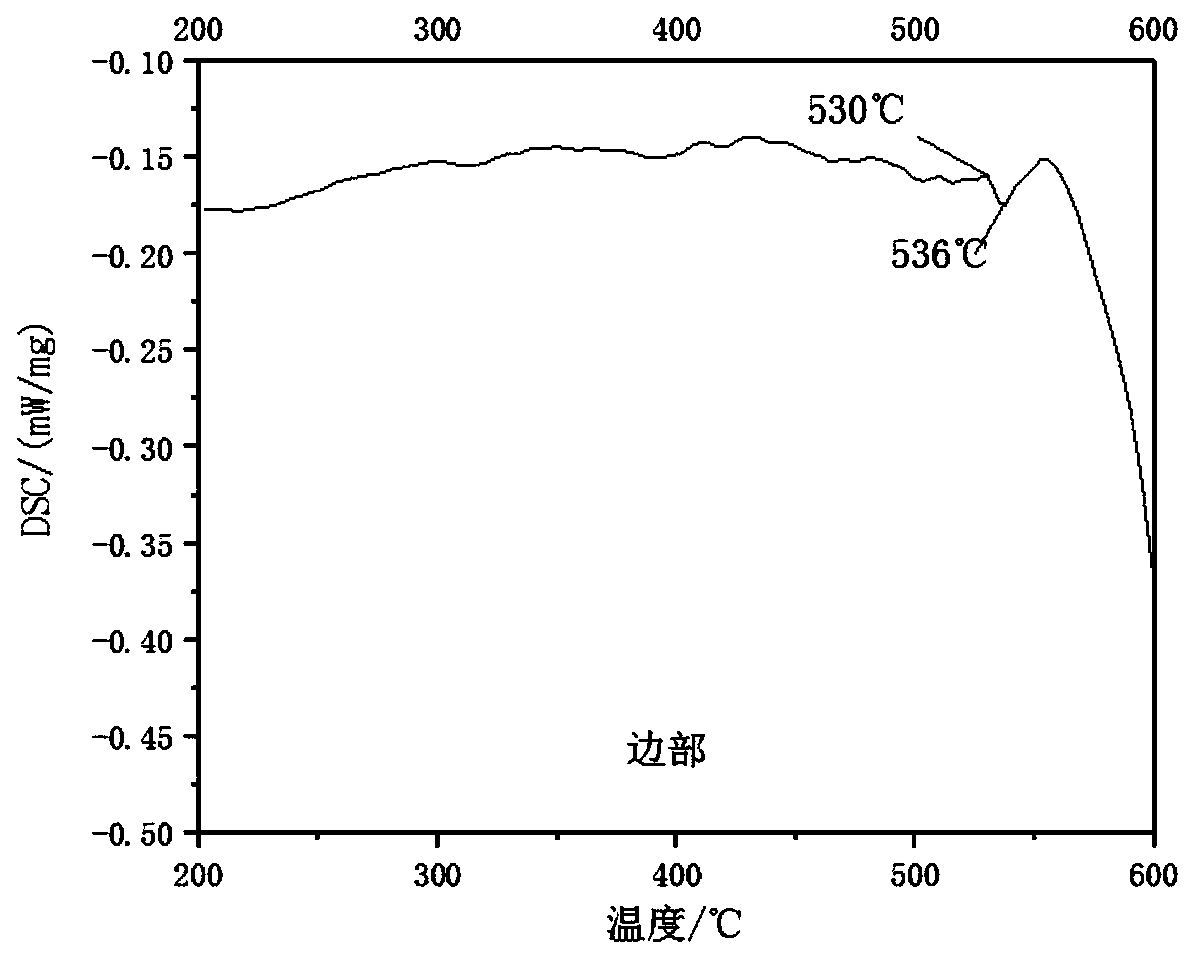

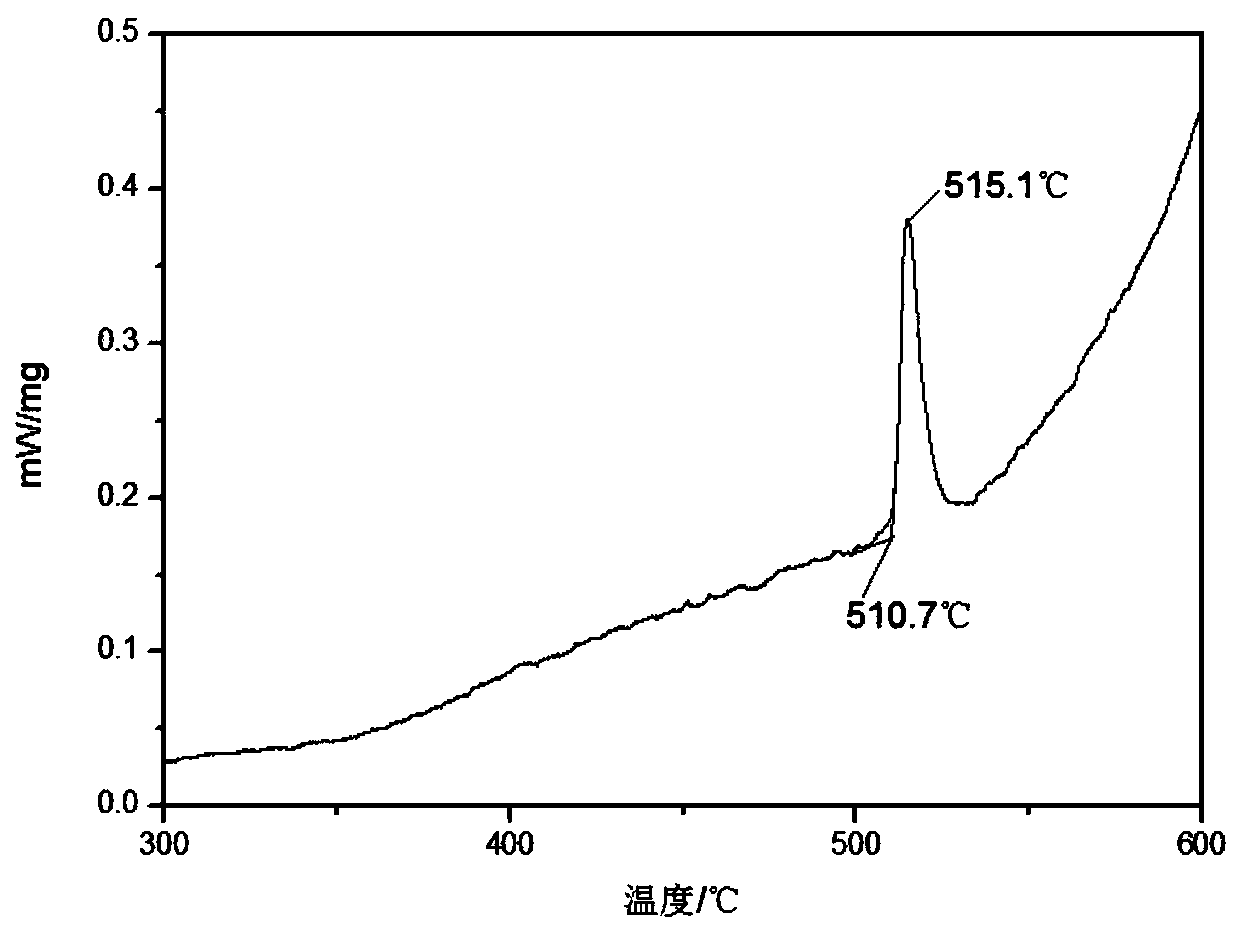

[0029] Step 2, the two-stage homogenization treatment is to perform a two-stage homogenization tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com