Water garbage clearing device for hydroelectric power station

A garbage cleaning and power station technology, which is applied in the cleaning of open water surfaces, water conservancy projects, construction, etc., can solve the problems of unsafe manual cleaning, and the water flow is not easy to put into garbage cleaning vehicles, etc., to achieve convenient transfer and transportation, simple structure, and guarantee The effect of job safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

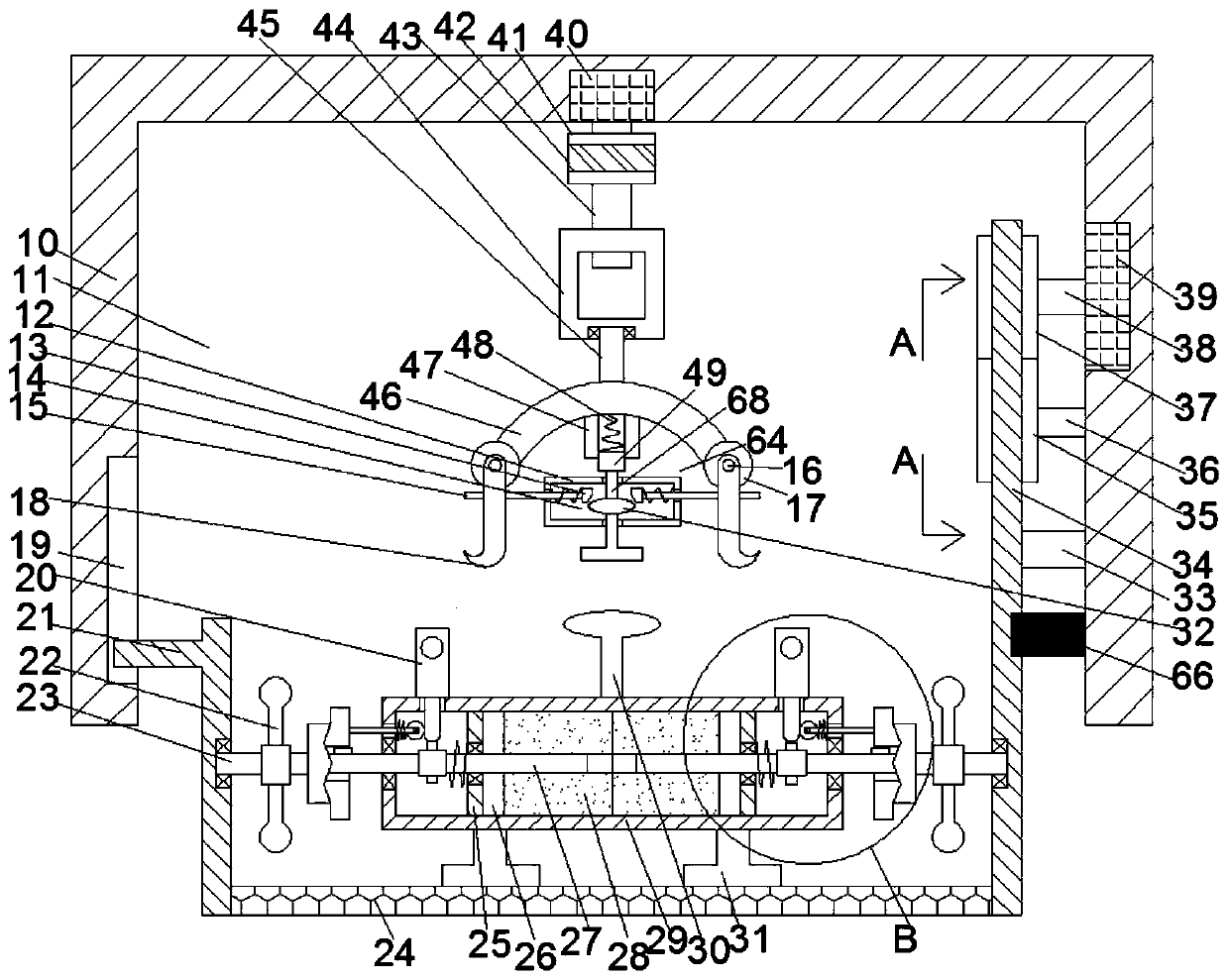

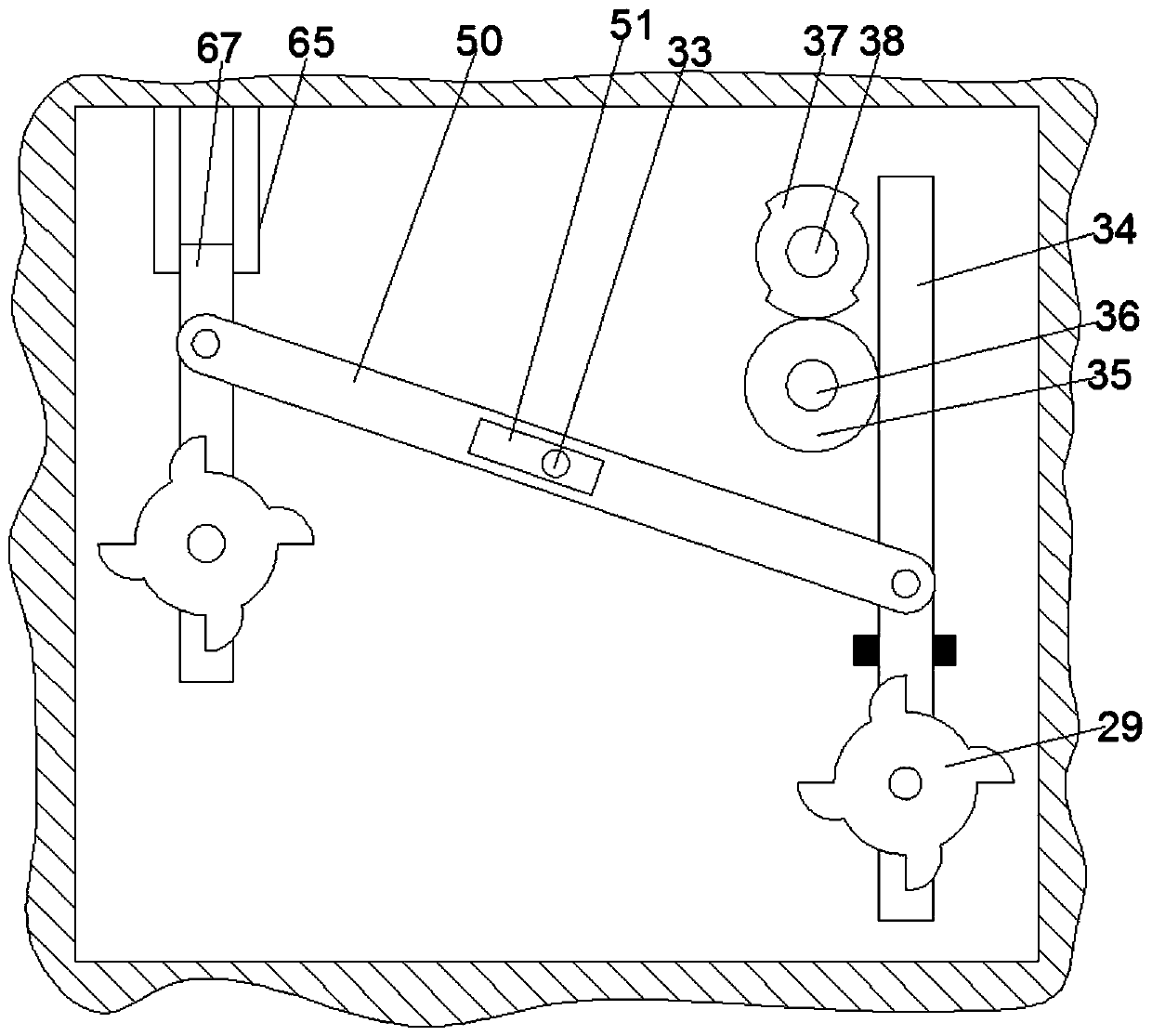

[0018] Combine below Figure 1-Figure 4 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

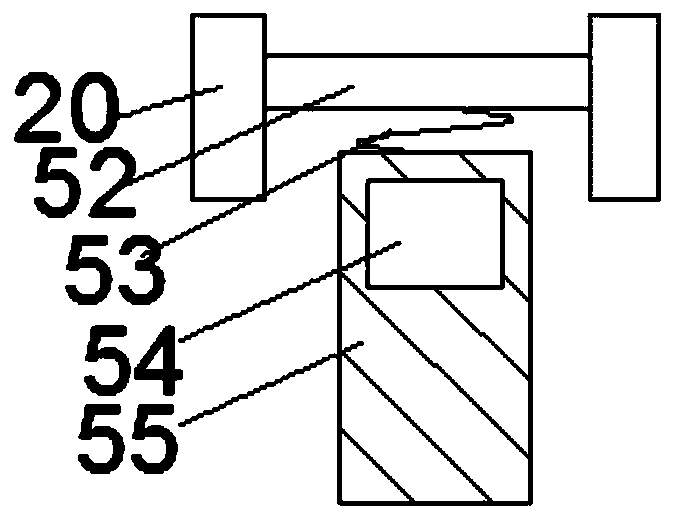

[0019] According to the present invention, a device for cleaning garbage in water in a water conservancy power station includes a water tank seat 10, and the water tank seat 10 is provided with an impurity removal chamber 11 that runs through the front and back and opens downward. There is a gate switch assembly, wherein, the gate switch assembly is provided with a rotating rod 50 extending forward and backward, and the front and rear ends of the rotating rod 50 are respectively hingedly connected with a longitudinal straight tooth plate 34 extending up and down and a driven hanging rod 67. The inner wall on the right side of the cleaning chamber 11 is provided with a front and b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com