Optical component weak absorption test device and method based on equivalent temperature

A technology of optical components and testing devices, which is applied in the field of testing the absorption rate of optical components, can solve the problems of limited testing accuracy and inability to test the absorption of opaque materials, and achieve the effects of large wavelength range, convenient and fast experimental operation, and simple optical path structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

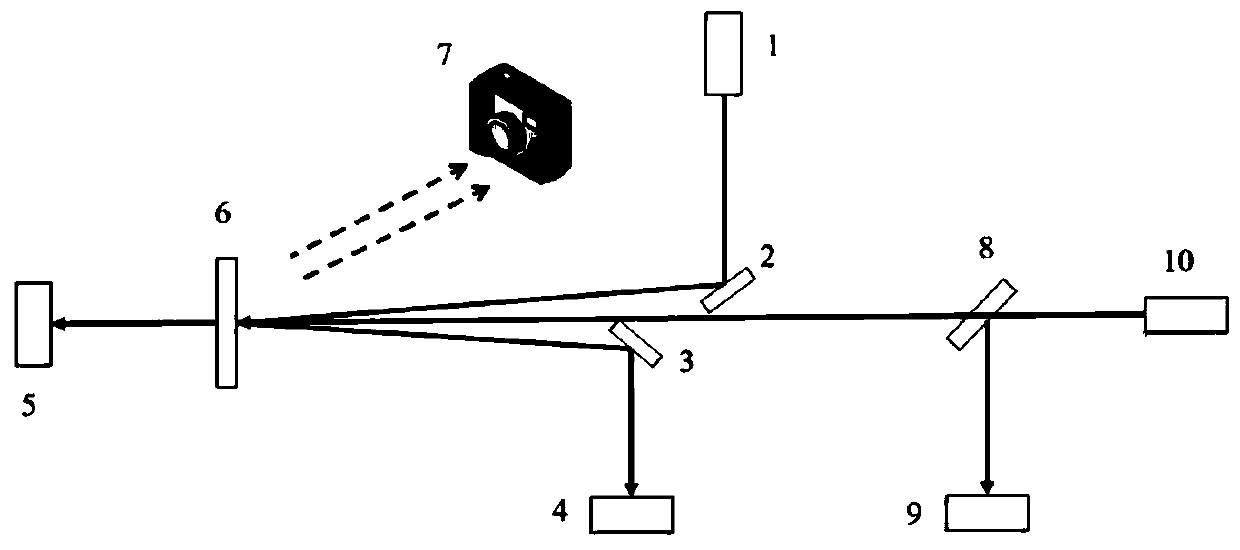

[0026] Describe the present invention in detail below in conjunction with accompanying drawing and embodiment:

[0027] Aiming at the existing problems in the existing film absorption testing technology, such as complex structure, large post-data processing error, and low testing efficiency, the present invention proposes a device and method for weak absorption testing of optical elements based on equivalent temperature.

[0028] Based on the principle of equivalent temperature: for a continuous laser, when the inward heat flow on the sample surface and the boundary conditions are the same, the temperature rise of the grating surface is the same; 10.6um CO 2 Lasers, dielectric thin films, quartz and other materials all absorb 1 at this wavelength. As a probe laser, it is beneficial to calculate the power absorbed by the surface of the sample; for a 1064nm continuous laser (take this wavelength as an example), only the power absorbed by the surface will be Heating the sample, u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com