Food waste disposal system and control method thereof

A food waste treatment and control module technology, applied in grain treatment, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problem of inability to adjust the water consumption of the garbage disposer, the single function of the food waste disposer, and the inability of the garbage disposer to function Expansion and other issues to achieve the effect of improving garbage disposal capacity, improving user experience, and enhancing scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

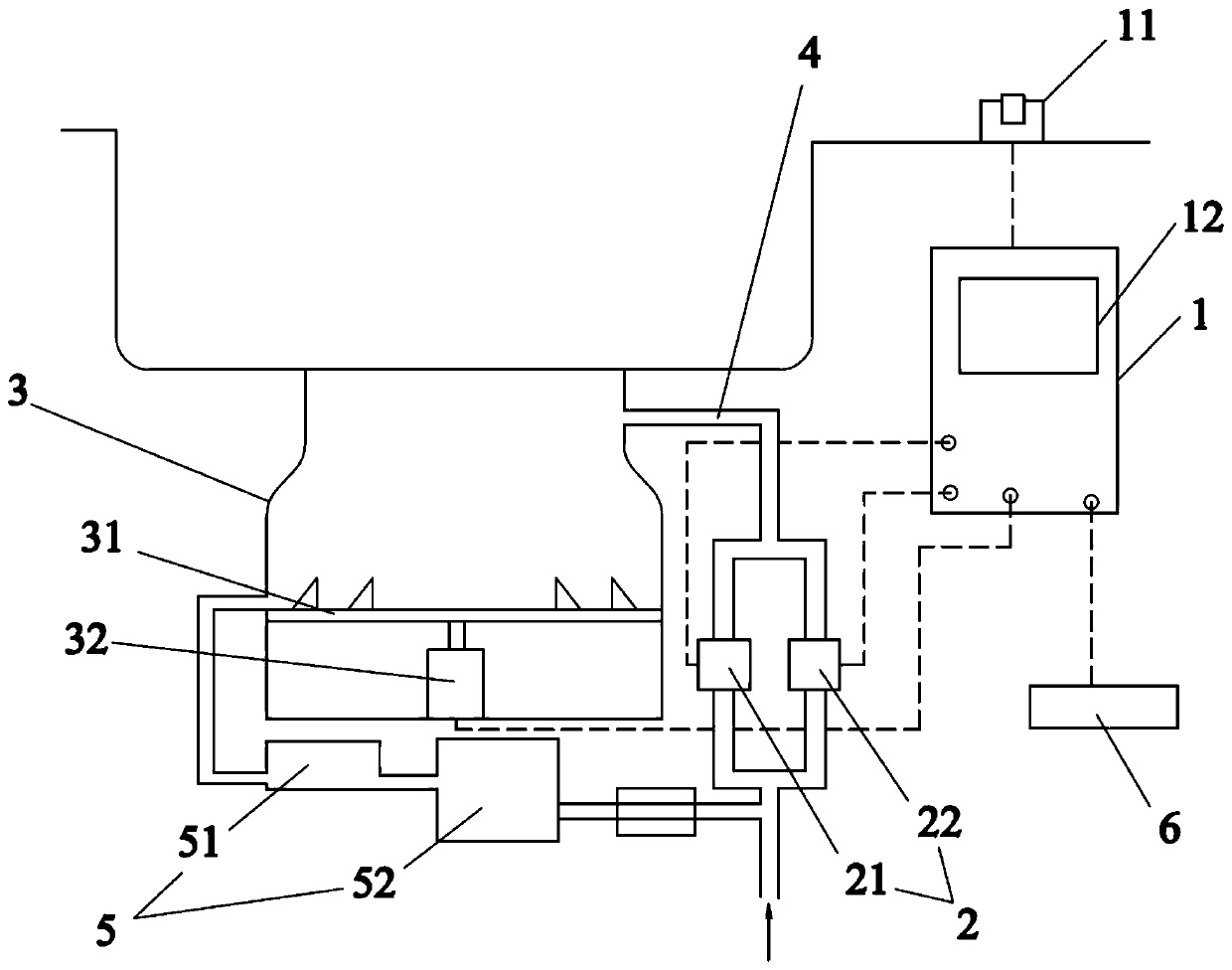

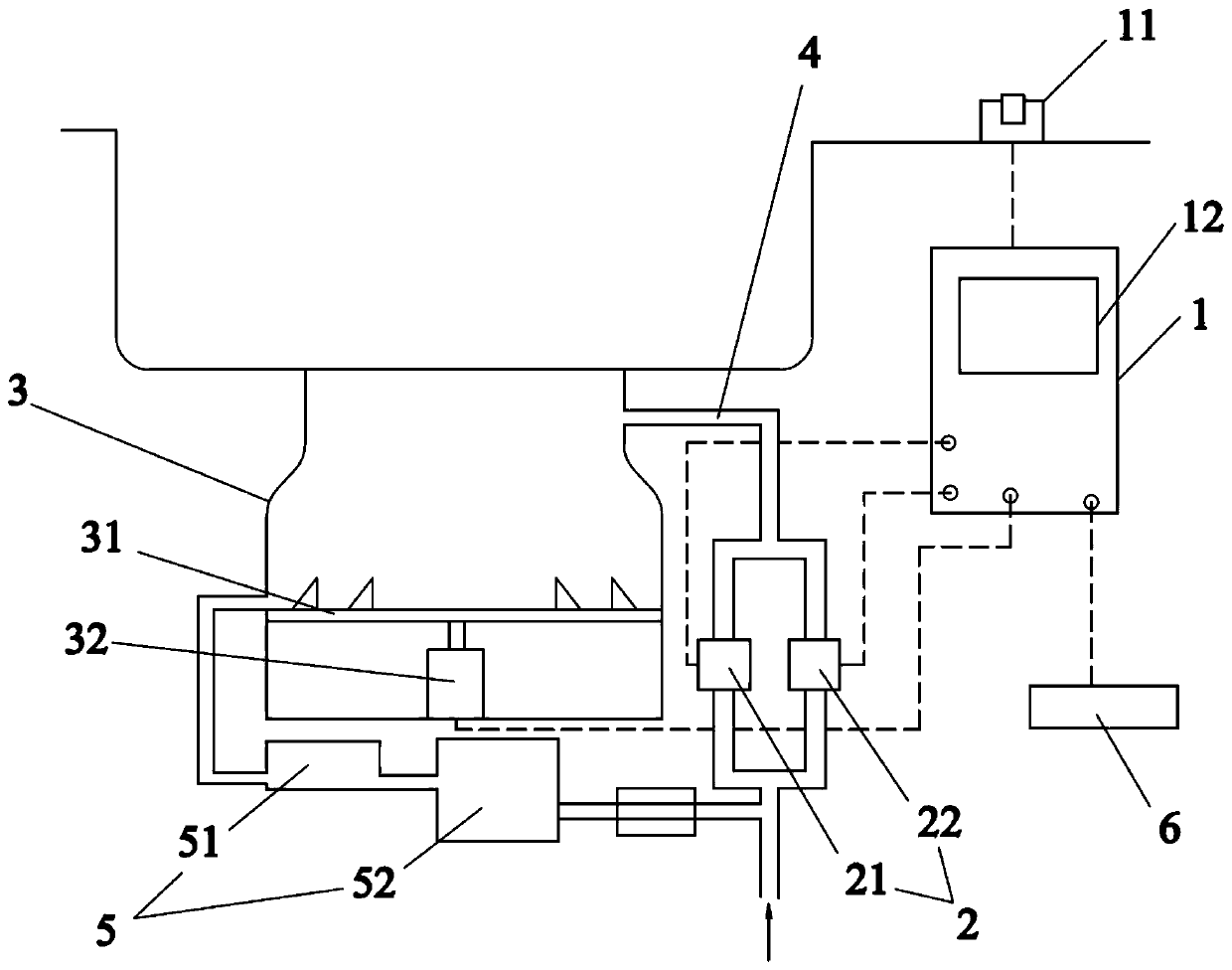

[0028] Such as figure 1 As shown, a food waste treatment system includes a control module 1, a valve 2 and a grinding chamber 3, the grinding chamber 3 is connected to a water supply pipe 4, the valve 2 controls the flow of the water supply pipe 4, and the control module 1 is connected to an air switch 11 , the air switch 11 controls the valve 2 through the control module 1 to adjust the water consumption of the grinding chamber 3 . The water supply pipe 4 is used to provide flushing water to the grinding chamber 3, which can improve the garbage disposal capacity of the grinding chamber 3, and also help to ensure that the ground garbage is washed out of the grinding chamber 3, so as to improve the use of the grinding chamber 3 Increase the service life of the valve 2. The valve 2 controls the flow of the water supply pipe 4 to avoid wasting flushing water; the control module 1 adjusts the flow of the water supply pipe 4 through the valve 2 by judging the magnitude of the press...

Embodiment 2

[0038] Such as figure 1 Shown, a control method of the food waste treatment system described in Embodiment 1, comprises the following steps:

[0039] 1) Pour food waste from the water tank drain into the grinding chamber 3, and press the air switch 11;

[0040] 2) The control module 1 sends a control signal to the valve 2 according to the flow rate of the water supply pipe 4 corresponding to the pressing range of the air switch 11;

[0041] 3) The valve 2 adjusts the flow rate of the water supply pipe 4 according to the control signal; if the control module 1 stops sending the control signal, the valve 2 is closed, and the water supply pipe 4 stops supplying water to the grinding chamber 3 .

[0042] It should also be noted that: in the control method of the present invention, in step 1), after pressing the air switch 11, the control module 1 also sends a running signal to the motor 32, so that the grinding mechanism 31 starts to work; in step 2), the control The panel 12 ca...

Embodiment 3

[0044] The difference from Embodiment 2 is that in step 2) of this embodiment, the control module 1 correspondingly opens the high flow valve 21 or the low flow valve 22 according to the speed at which the air switch 11 is pressed, and sends a control signal to the high flow valve 21 or the low flow valve. Flow valve 22. When the control module 1 detects that the air switch 11 is pressed quickly, the control module 1 independently controls the high flow valve 21 to open; when the control module 1 detects that the air switch 11 is slowly pressed, the control module 1 controls the low flow valve 22 independently Turning it on helps to enhance the scalability of the system, and makes the control more flexible and the operation more humanized.

[0045] Other steps are the same as those in Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com