Robot dynamic tracking and grabbing system and method of easily-damaged articles

A dynamic tracking and robotic technology, applied in conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of insufficient robot grasping accuracy, particularly high accuracy requirements, and vulnerable items, etc., to reduce time and improve. The effect of grasping precision and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with specific embodiment, further illustrate the present invention.

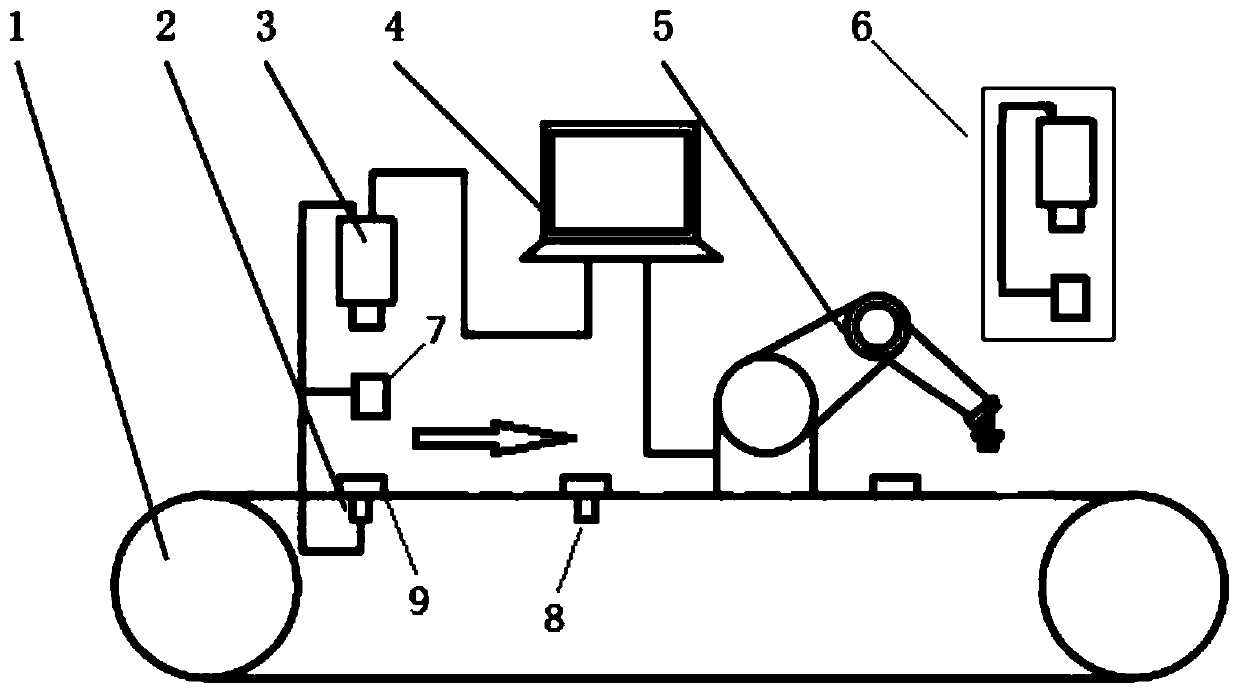

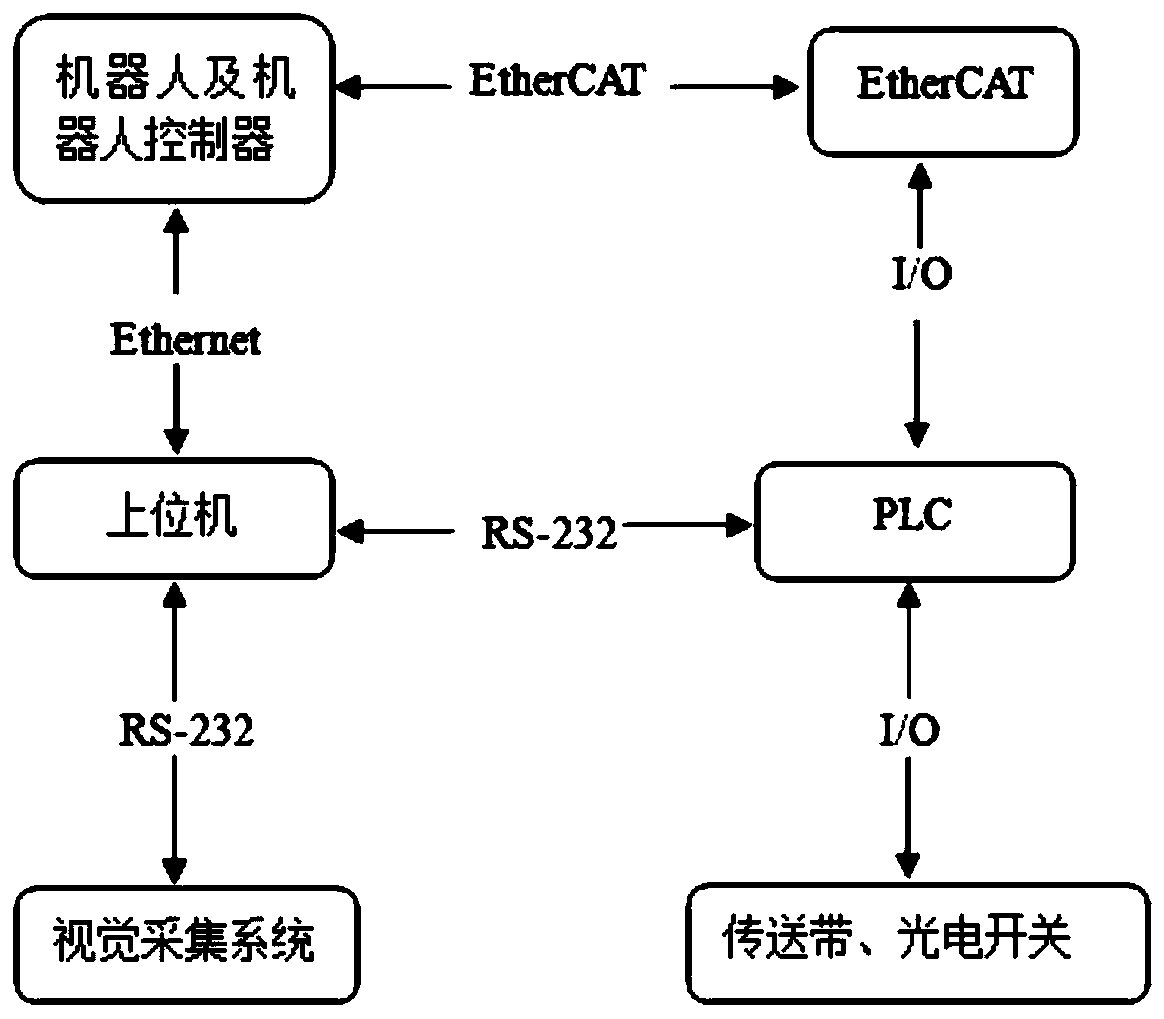

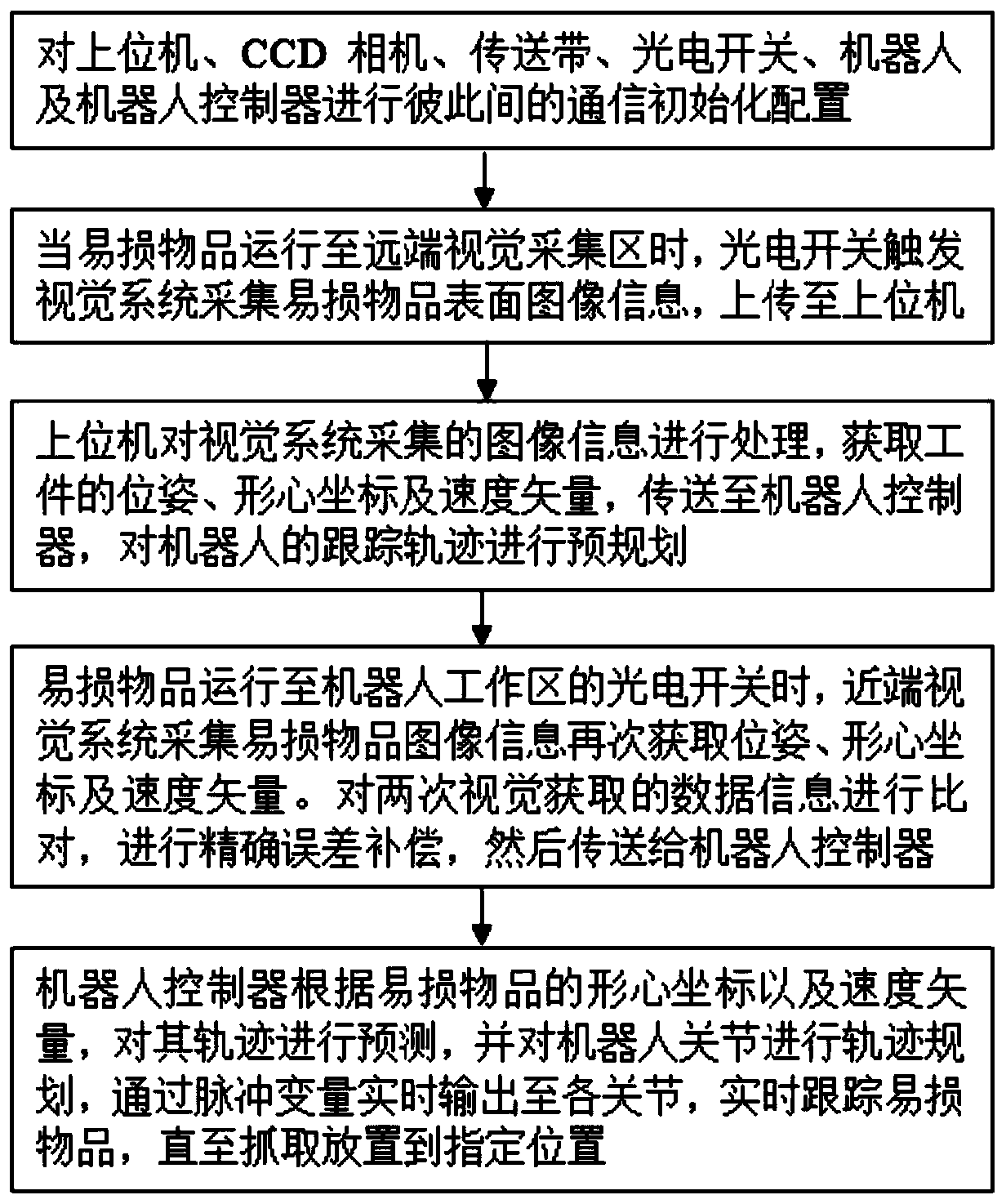

[0033] figure 1 The overall structure diagram of the robot dynamic tracking and grabbing system for vulnerable items provided in this embodiment, the robot dynamic tracking and grabbing system for vulnerable items includes a host computer 4, a robot 5, a robot controller, an end effector, PLC control system, conveyor belt 1, first photoelectric switch 2, second photoelectric switch 8, vulnerable items 9, CCD camera 3, image acquisition card and light source 7, etc. The remote vision system consists of a CCD camera 3 fixed at the beginning of the conveyor belt 1, an image acquisition card and a light source 7, and takes vertical shots of the vulnerable items 9 on the conveyor belt to obtain image information. The near-end vision system 6 is fixed directly in front of the robot 5, that is, takes pictures from the side directly in front to obtain image information of vulnerable item...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com