Polyurethane composition, and polyurethane foam body and applications thereof

A polyurethane foam and composition technology, applied in the field of polyurethane foam, can solve the problems of car seat comfort requirements and odor improvement without consideration and improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

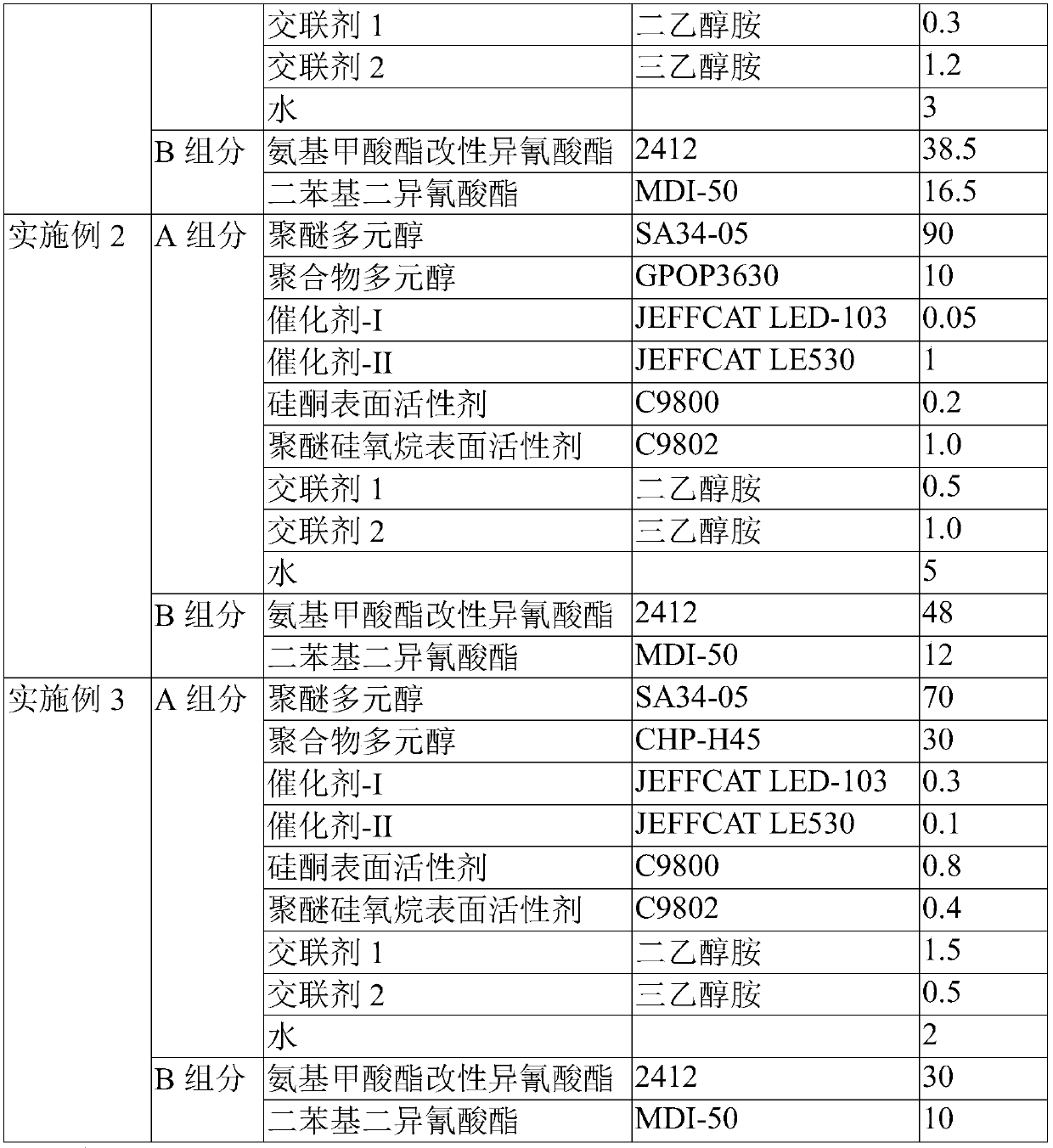

[0073] Polyurethane foam molding was carried out according to the raw materials and dosage listed in Table 1.

[0074] According to Table 1, stir each component of component A evenly. Add 100 parts by weight of component A and the amount of component B shown in Table 1 into a high-pressure foaming machine, perform high-pressure mixing at 12MPa, and then pour into a mold at 60°C for foaming.

[0075] The foam was taken out and allowed to stand for aging for 12 hours to obtain a polyurethane foam.

[0076] The polyurethane foam was tested for odor, comfort and other properties, and the results are shown in Table 2.

[0077] Table 1

[0078]

[0079]

[0080] Table 2

[0081]

[0082]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com