Method for determining tool face angle in three-dimensional borehole trajectory control

A technology of tool face angle and wellbore trajectory, which is applied in wellbore/well components, directional drilling, earthwork drilling and production, etc., can solve the problems of lower drilling efficiency, failure to hit the target, and long time consumption, so as to improve drilling efficiency and save The effect of daily drilling cost and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Taking a 3D horizontal well in Jinghe Oilfield, Ordos Basin as an example, this example is to control the wellbore trajectory by drilling a string of drill pipe in the 3D directional well section. The specific steps of the method for determining the tool face angle in the three-dimensional wellbore trajectory control in this embodiment are as follows:

[0024] (1) In the initial section of the 3D directional well, the actual build-up rate of the drill tool assembly is determined according to the deflection measurement data of the 2D directional section. The drilling tool assembly of this well section is shown in Table 1:

[0025] Table 1. Relevant values of 2D directional drilling tools

[0026] name steel grade Inner diameter×outer diameter(mm) Buckle type Quantity (root) length (m) 8 1 / 2 "Teeth wheel

dedicated 215.9 431 1 0.33 1.5° screw special material 35×172 430×410 1 8.30 non-magnetic special material 72...

Embodiment 2

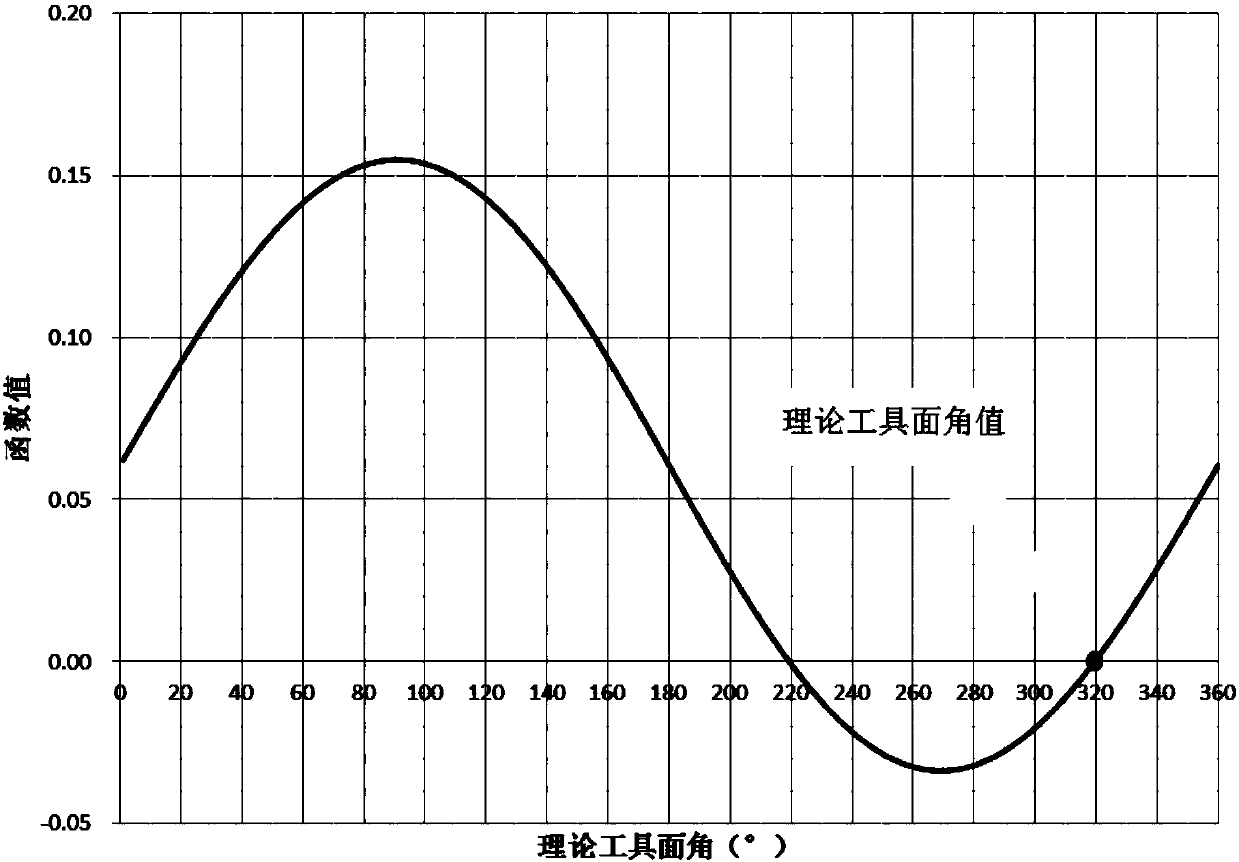

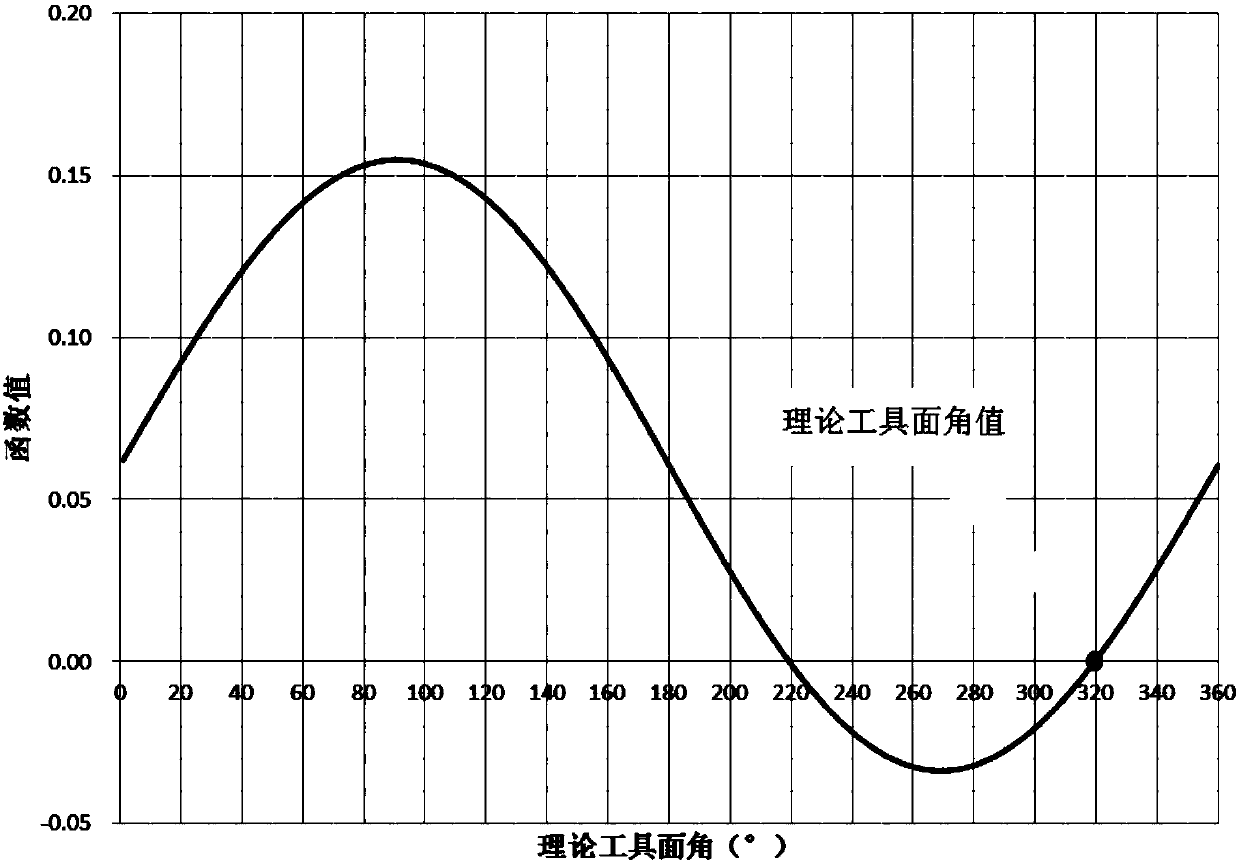

[0046] The specific steps of the method for determining the tool face angle in the three-dimensional wellbore trajectory control in this embodiment are as follows:

[0047] (1) For a three-dimensional horizontal well, the build-up rate of the drilling tool assembly is 3.75° / 30m. In the three-dimensional directional well section, it is drilled to 1414.74m, ready for the next string of drill pipe construction.

[0048] (2) Determine the numerical values used in Formula I.

[0049] A. According to the MWD inclination measurement data, after calculation, the bottom hole inclination angle is α 1 =59.45°, the well inclination azimuth is Φ 1 =15.60°, actual drilling vertical depth is D 1 =1321.47m;

[0050] B. After measurement, the length of the drill pipe to be lowered is ΔL=27.18m (generally composed of 3 single pieces);

[0051] C. The vertical depth D of the point to be drilled 2 =1334.97m, the azimuth angle of well inclination is twisted to Φ 2 =12.80°;

[0052] D. On-si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com