Hydraulic adjusting device and plunger piston

A technology of hydraulic adjustment device and plunger, which is applied in the direction of valve device, engine components, machine/engine, etc., which can solve the problems of increasing the manufacturing cost of parts, and achieve the effect of facilitating discharge, reducing processing cost and concentrating gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] It can be seen from the background art that the gap between the plunger and the housing of the hydraulic adjustment device is related to the accuracy of the oil leakage control time, which leads to high processing cost of the plunger.

[0047] Now combine a hydraulic gap adjuster to analyze the reason.

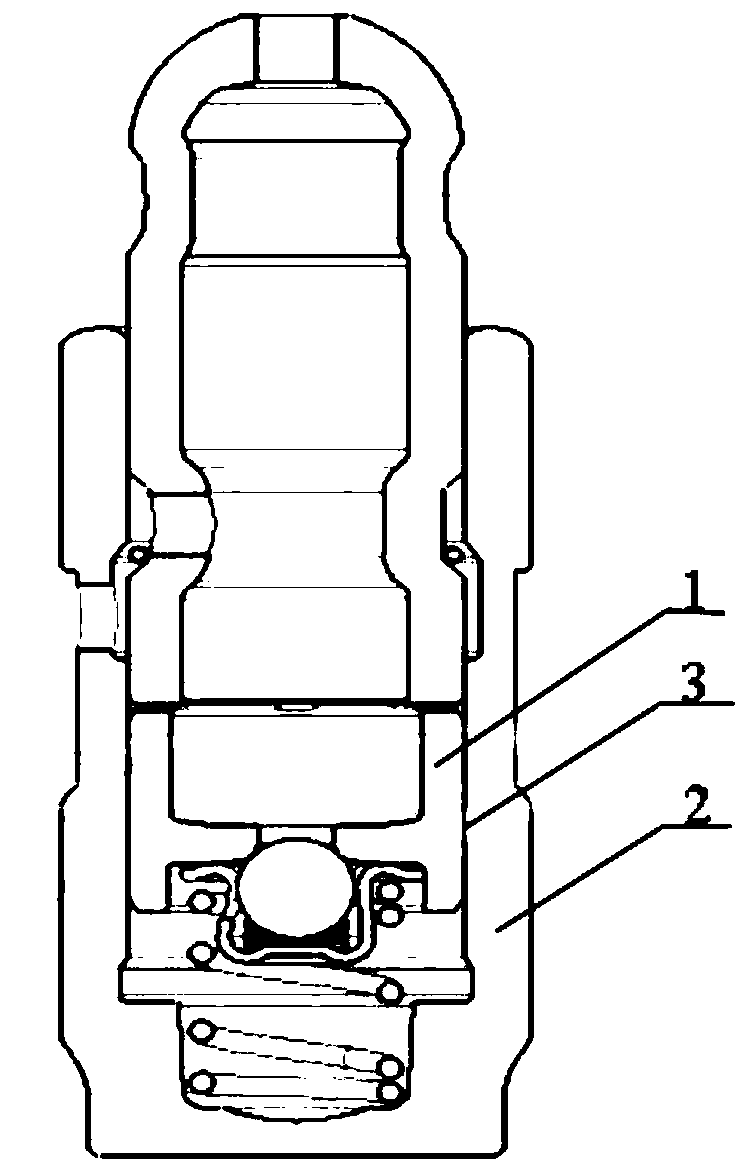

[0048] Please refer to figure 1 , figure 1 It is a sectional view of a gap adjuster.

[0049] like figure 1 As shown, there is a gap 3 between the housing 2 and the plunger 1 of the clearance adjuster, so that the leakage oil in the high pressure chamber leaks out along the gap 3, however, due to the gap 3 between the housing 2 and the plunger 1 determines Therefore, the machining accuracy of the contact area between housing 2 and plunger 1 is high. Moreover, due to the different oil leakage descending time required by customers, it is necessary to select and match the plunger and housing in groups, which is time-consuming. exhausting.

[0050] In order to solve th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com