Hosepipe

A technology for hoses and snakeskin tubes, applied in the directions of hoses, pipes, pipes/pipe joints/fittings, etc., can solve the problems of low production efficiency, poor dimensional stability, and elongated hoses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

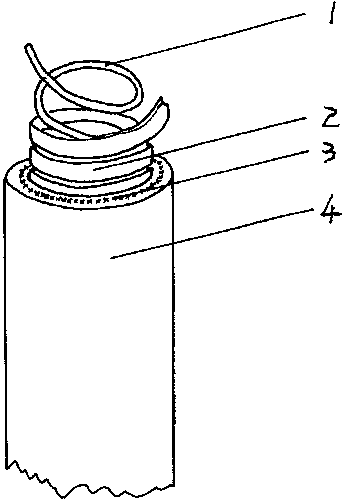

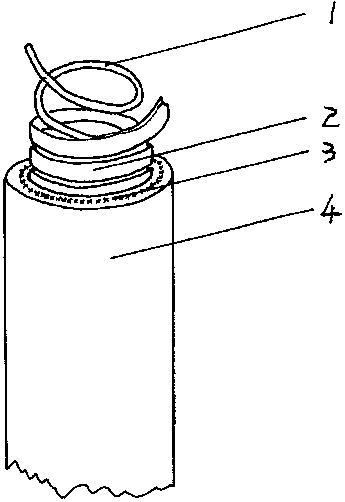

[0005] exist figure 1 Among them, the large-pitch spring 1 is movably connected with the double-button galvanized spiral snakeskin tube 2, and the double-button galvanized spiral snakeskin tube 2 is fixedly connected with the rubber tube 3, and the three are closely integrated. The cross-section of the inner layer is circular, with a diameter of 2-20 mm, or rectangular, high-carbon steel rod or wire with a width and thickness of 2-20 mm, made into a large pitch according to the diameter of the double-button galvanized spiral coil The spring 1 has a pitch of 2 to 50 mm; the material of the middle layer is a double-button galvanized spiral snakeskin tube 2 made of low carbon steel sheet, copper plate and stainless steel plate with a thickness of 0.5 to 4 mm, and its pitch is 2 to 20 mm The outer layer is made of a nitrile rubber tube 4 or a rubber-plastic tube sandwiched with a cord fabric 3. The inner layer of the rubber tube 4 is 0.1 to 1 mm thick, the cord fabric 3 is 0.01 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com