Soft-packing battery high vacuum micro-channel water removing device

A soft-pack battery and high-vacuum technology, applied in heating devices, lighting and heating equipment, drying, etc., can solve problems such as difficulty in ensuring consistent temperature, low heat exchange efficiency, and increased time costs, so as to prevent water resurgence, Low energy consumption and improved sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

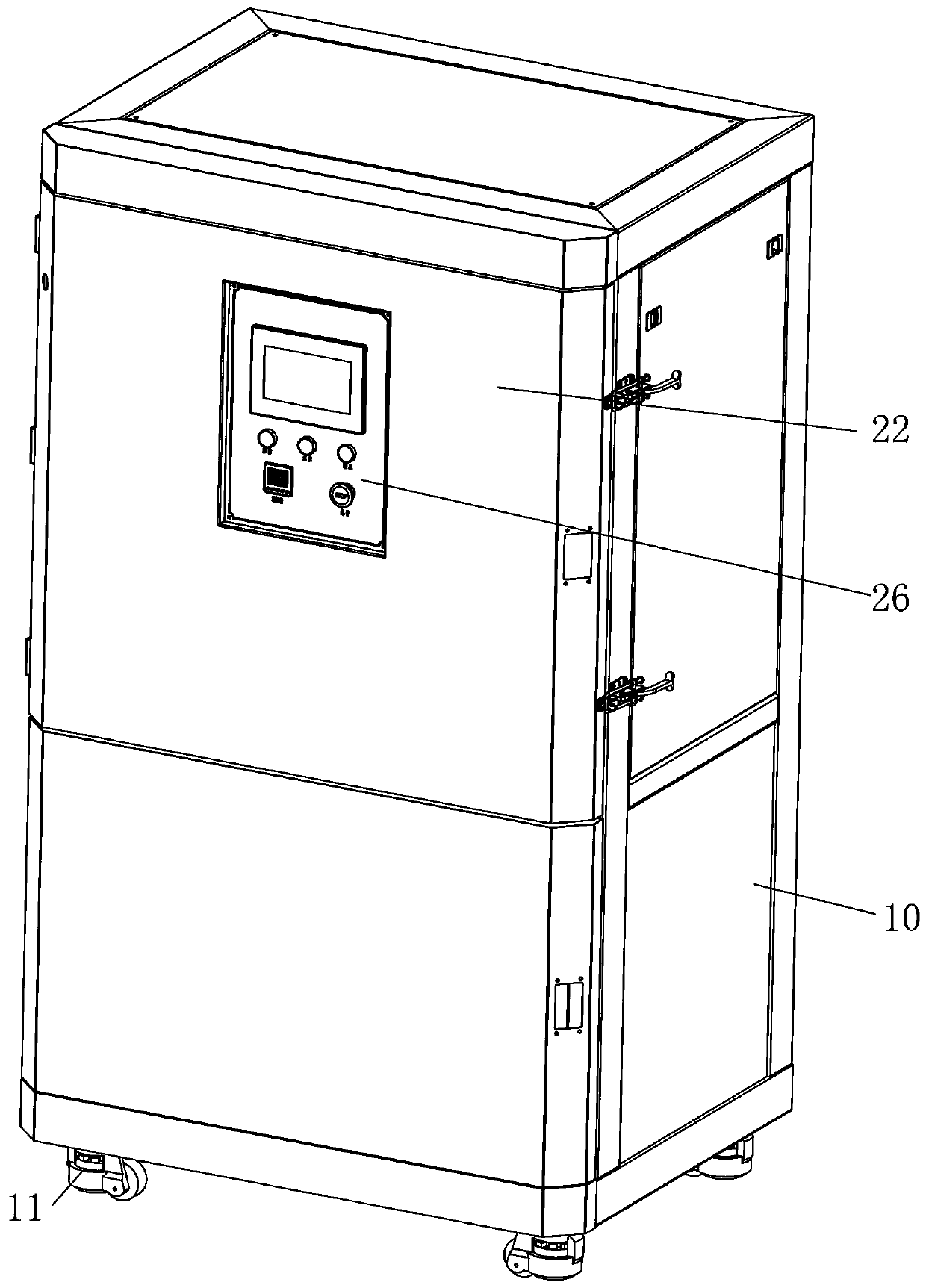

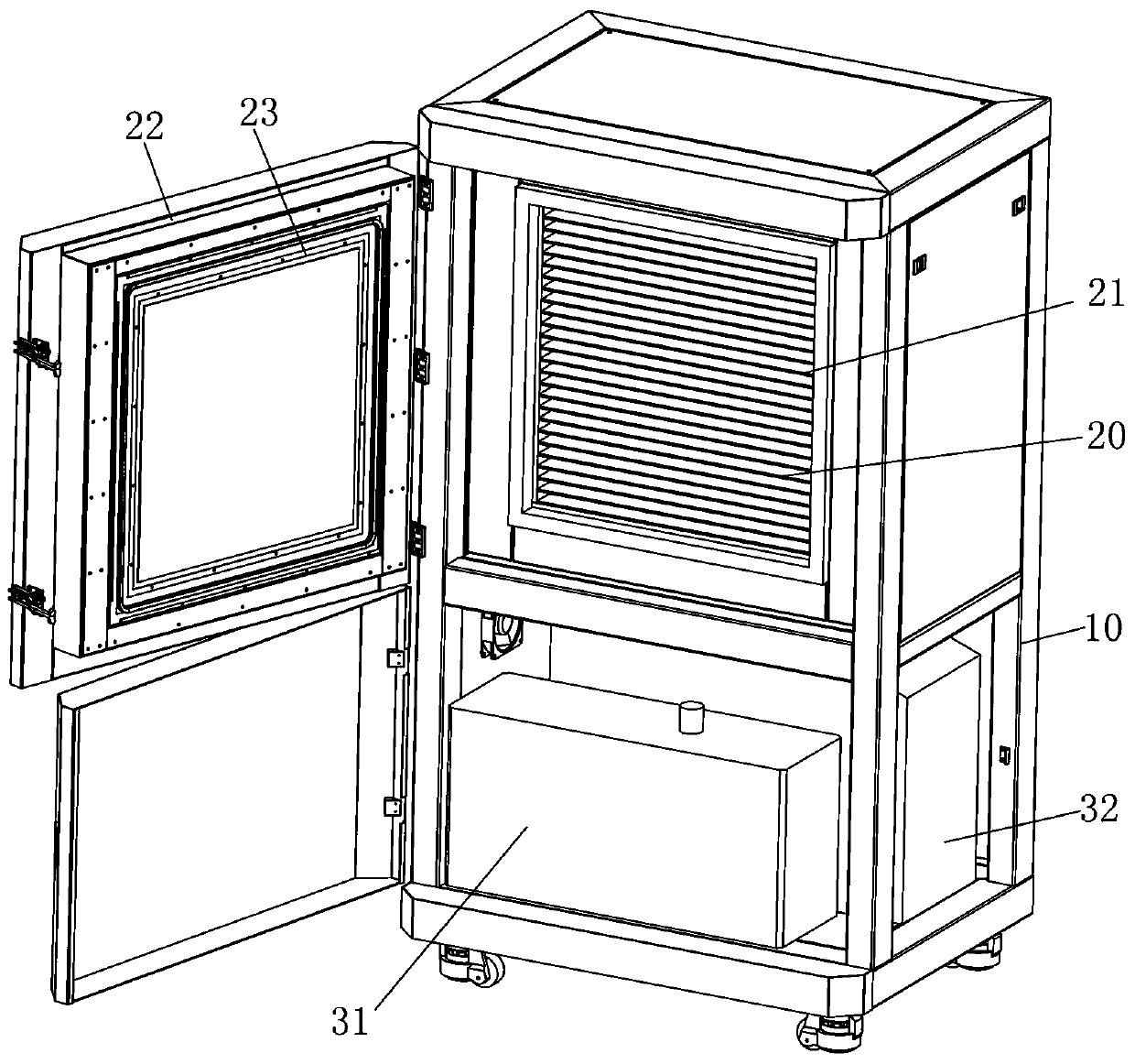

[0031] Such as Figure 1-3 As shown, the embodiment provided by the present invention is a high-vacuum micro-channel dewatering device for a pouch battery, which includes a frame 10 on which a high-vacuum chamber 20, a hot liquid tank 31 and a cold liquid tank 32 are arranged. .

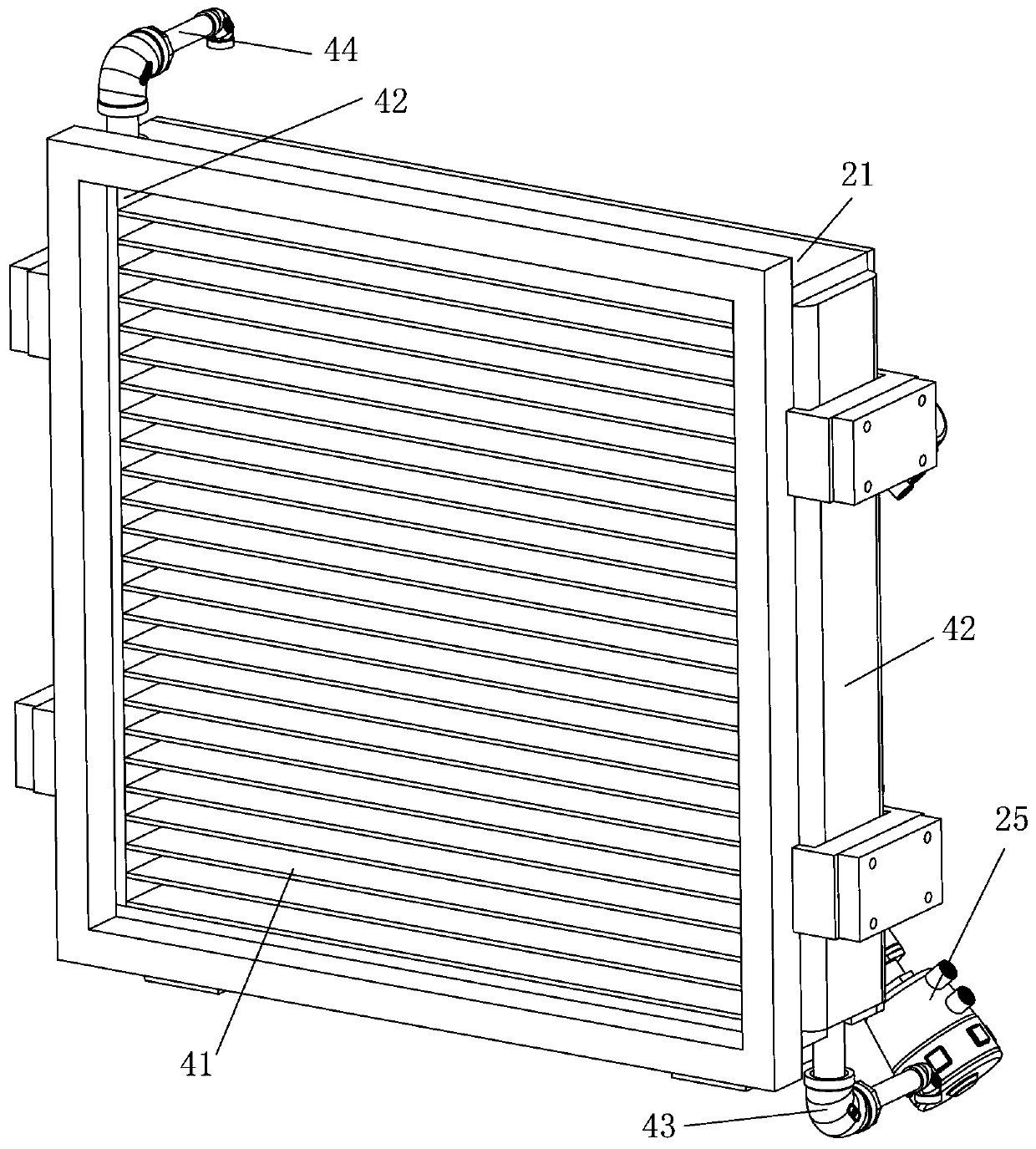

[0032] Microchannel flat tubes 41 and collectors 42 are arranged in the high vacuum cavity 20, and a plurality of microchannel flat tubes 41 distributed up and down are arranged between the two collectors 42, and the collectors 42 and the microchannel flat tubes 41 in communication; the hot liquid tank 31 and the cold liquid tank 32 are in circulation communication with the two headers 42 through water pumps, valves and pipelines. Wherein, the hot liquid tank 31 is provided with a heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com