Alignment ultraviolet meter

A technology of aligning ultraviolet rays and cavities, applied in nonlinear optics, conveyor objects, optics, etc., to achieve the effect of flexible product layout and increased production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

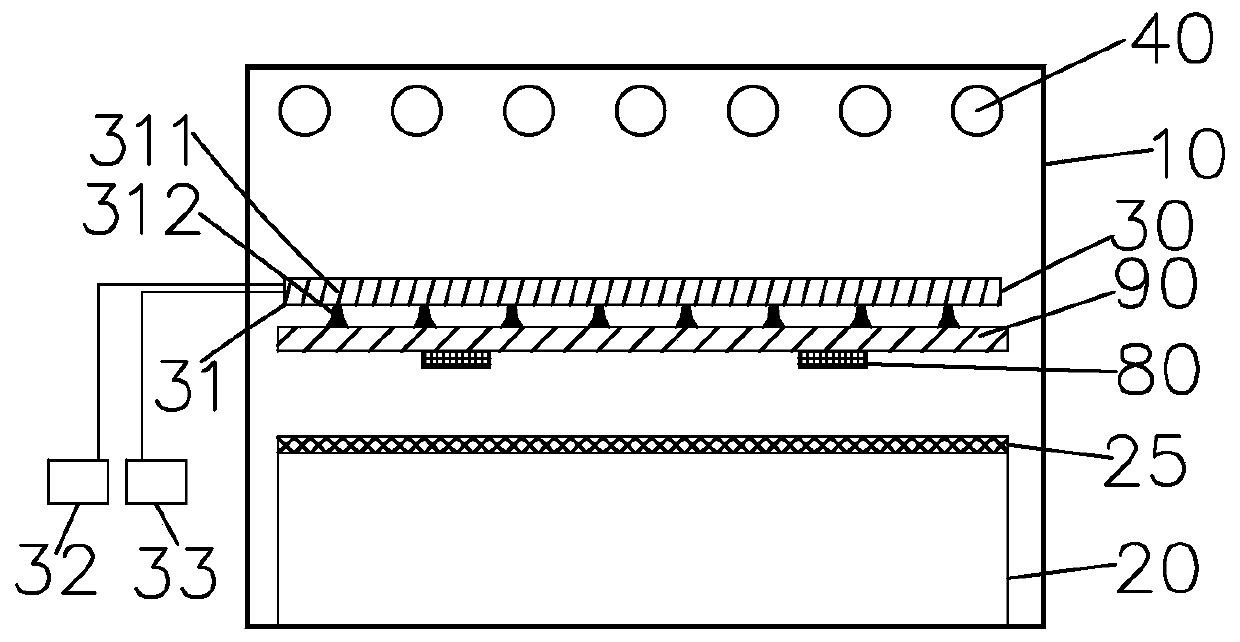

[0030] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

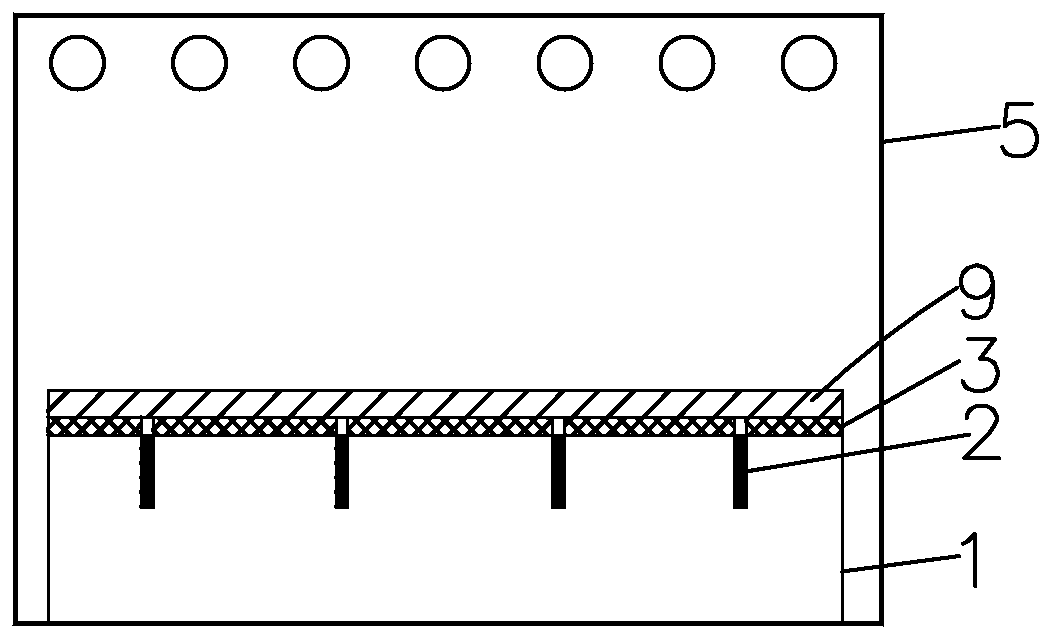

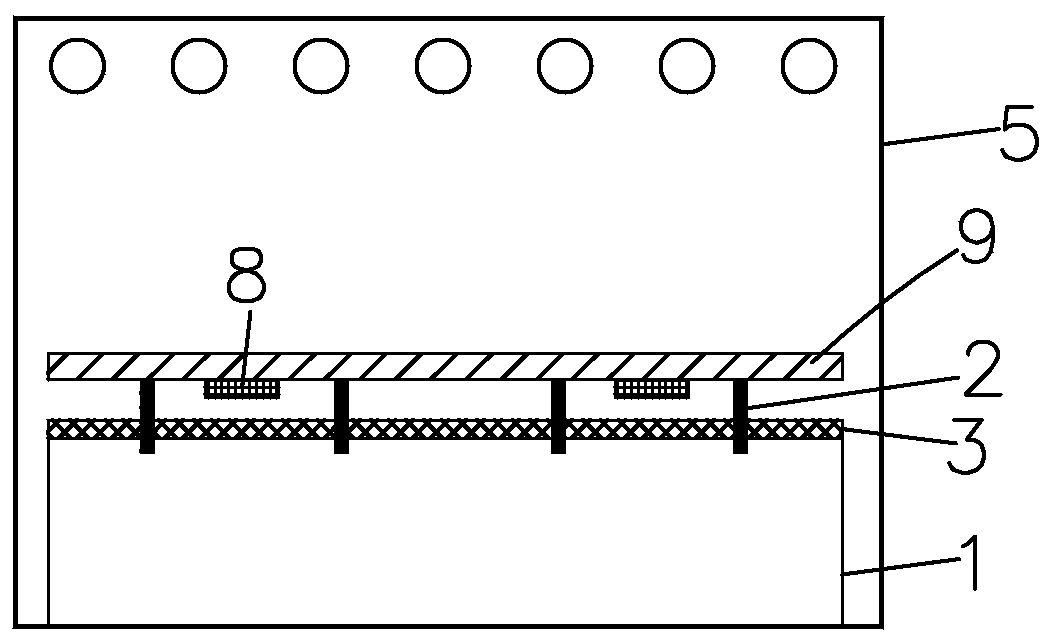

[0031] see Figure 3-4 , the present invention provides an aligned ultraviolet irradiation machine, comprising a cavity 10, an ultraviolet lamp group 40 disposed on the top of the cavity 10 for emitting ultraviolet light, and a heating device disposed in the cavity 10 below the ultraviolet lamp group 40 The platform 20, the heat conduction plate 25 for carrying the display panel 90 provided on the upper surface of the heating platform 20, the temperature control system (not shown) for controlling the temperature of the heating platform 20 and installed in the cavity 10 The outer side is used for the vacuum adsorption mechanism 30 for taking and placing the display panel 90 on the heat conducting plate 25 .

[0032] The vacuum suction mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com