Intelligent double-sided switch cubicle for high-voltage reactive power compensation

An intelligent, switchgear technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation, busbar/line layout, etc., can solve the problems of large volume, high cabinet shape, high transportation cost, and improve the advanced , the effect of reducing the height and widening the protection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

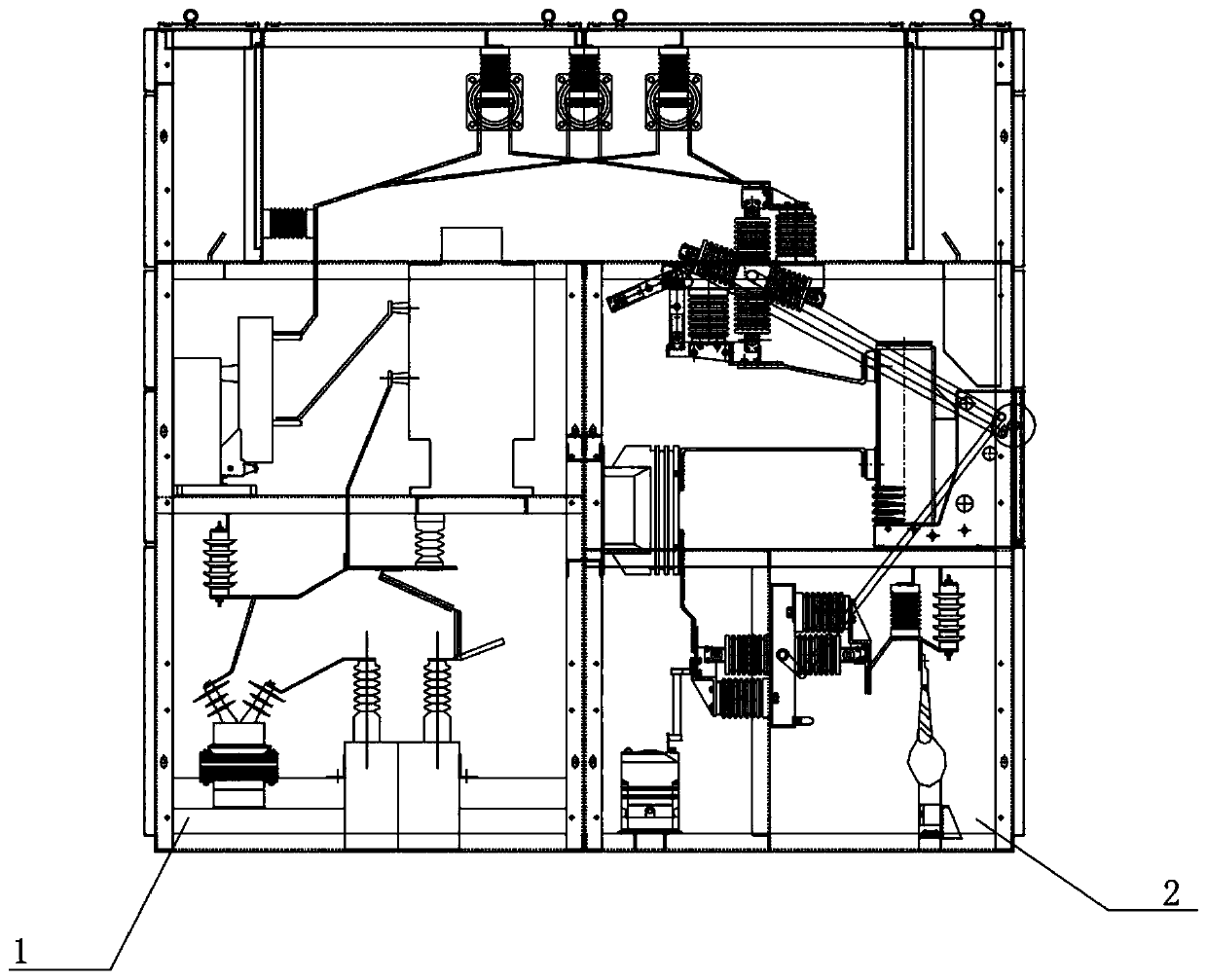

[0028] An intelligent high-voltage reactive power compensation double-sided switchgear, such as figure 1 and Figure 6 As shown, including compensation module power distribution cabinet 1 and incoming line module power distribution cabinet 2;

[0029] Both the compensation module power distribution cabinet 1 and the incoming line module power distribution cabinet in the intelligent high-voltage reactive power compensation double-sided switchgear of this embodiment adopt SZGW-12 type cabinets, and the size is 1100*1200*2300mm.

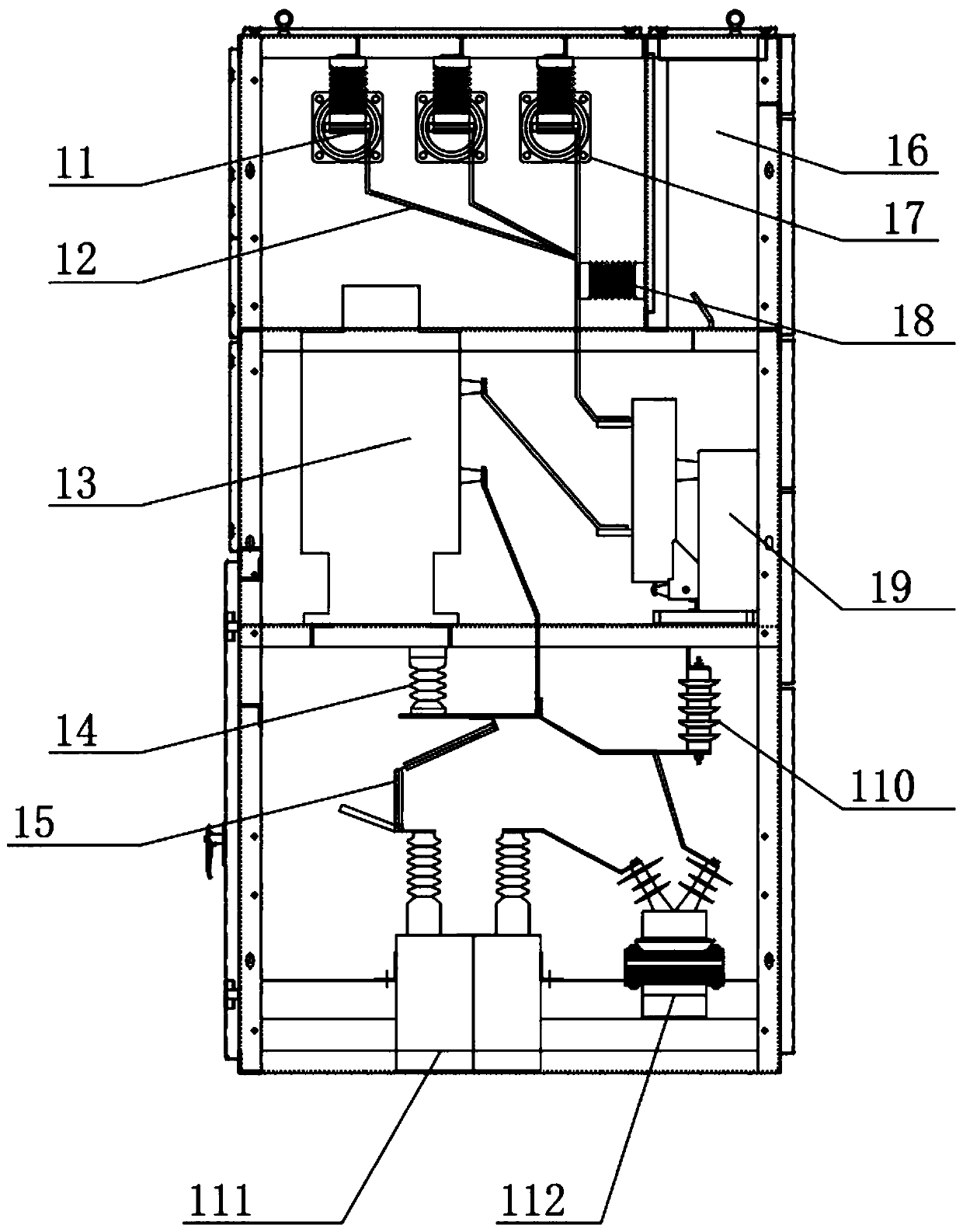

[0030] Further, such as figure 2 As shown, the compensation module power distribution cabinet 1 includes a first shell 113. The interior of the first shell 113 is divided into three layers. The top of the top layer is equipped with three wall-through bushings 17 that are evenly spaced and linearly arranged. A horizontal busbar 11 is installed in the bushing 17, and the upper branch line 12 is connected to the horizontal busbar 11. The first instrumen...

Embodiment 2

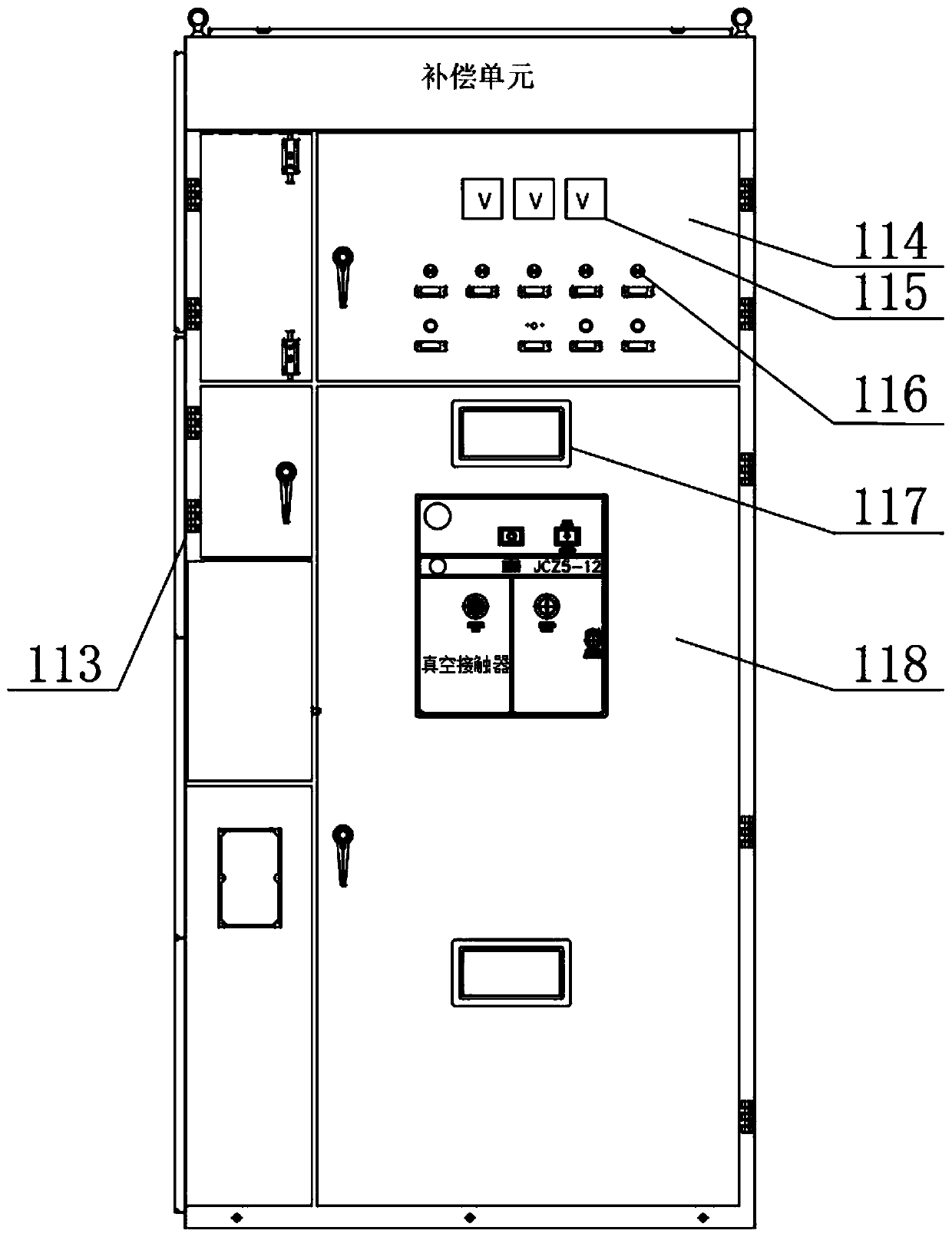

[0039] As a second preferred embodiment of the present invention, such as image 3 As shown, the topmost outer wall of the first housing 113 is provided with a first instrument door 114, and the first instrument door 114 is provided with three voltmeters 115 and a plurality of first indicator lights 116 arranged evenly and equidistantly. The middle layer and the bottom layer share a first lower door 118, and two first observation windows 117 are installed on the surface of the first lower door 118.

[0040] Further, one side edge of the first instrument door 114 and the first lower door 118 is connected to the first shell 113 through a hinge.

[0041] In addition, if Figure 5 As shown, the topmost outer wall of the second housing 215 is provided with a second instrument door 217, and three ammeters 218, an automatic compensator 216, several second indicator lights 219 and a microcomputer protector 222 are installed on the second instrument door 217. The middle layer and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com