Isolated upper bridge bootstrap charge pump circuit for bridge driver and control method

A driver and isolation technology, applied in the field of semiconductor hybrid integrated circuits, can solve the problems of unsupplemented electric charge, application limitation, complex circuit structure, etc., and achieve the effects of improving assembly efficiency, strong scalability, and high isolation voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

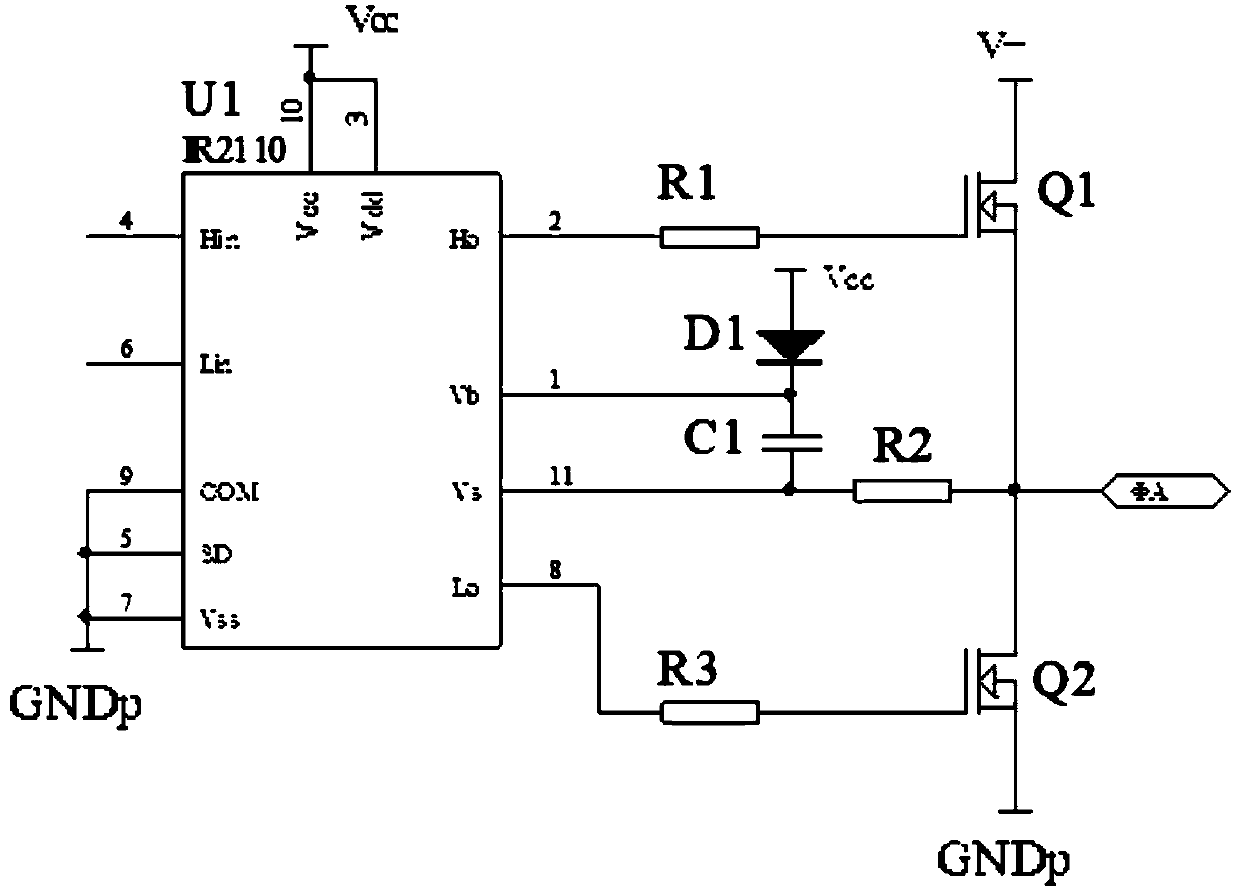

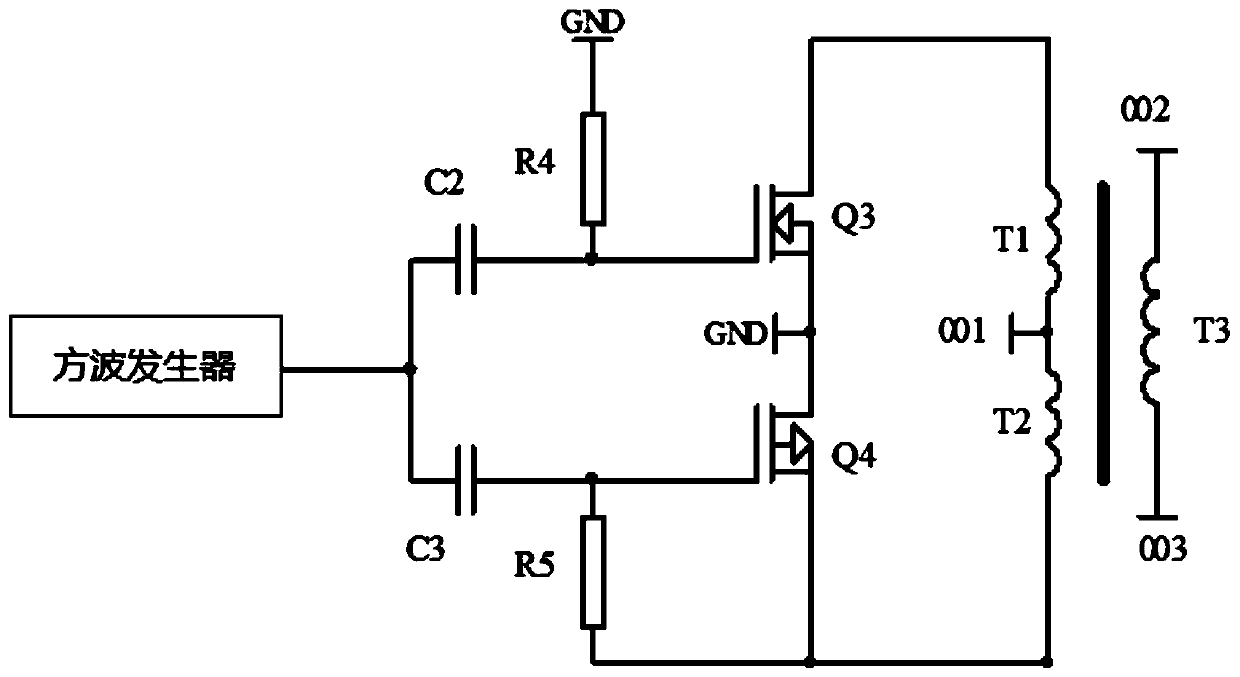

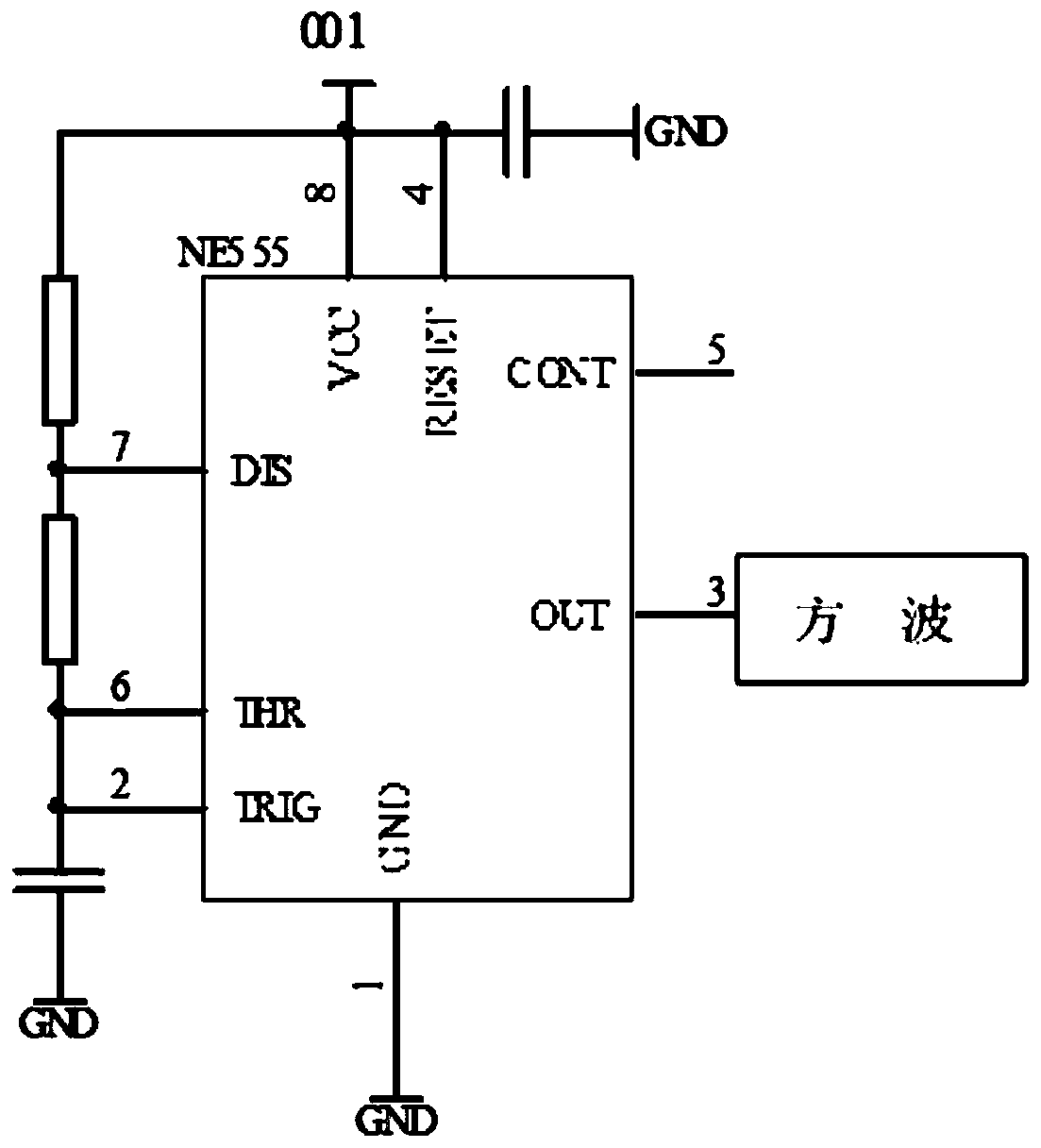

[0035] The invention relates to an isolated upper bridge bootstrap charge pump circuit for a bridge driver, comprising a square wave generator, two sets of pulse conversion circuits, a switch circuit and a transformer output circuit.

[0036] Among them, the square wave generator generates a square wave with a certain frequency and duty cycle, and connects capacitors C2 and C3 in parallel, the other end of capacitor C2 is connected in parallel with resistor R4 and the gate of N-type VDMOS Q3, and the other end of resistor R4 is grounded; The other end of the capacitor C3 is connected in parallel with the resistor R5 and the gate of the P-type VDMOS Q4, the other end of the resistor R5 is connected in parallel with the source of the P-type VDMOS Q4 and one end of the primary winding T2 of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com