Battery charging and discharging test method and system based on energy storage PCS (Power Conversion System) + BMS (Battery Management System)

A charge-discharge test, charge-discharge technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of high cost, low production capacity, and many testing equipment, and achieve small investment, reduced investment, and strong scalability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with embodiment the present invention is further described.

[0033] A battery charge and discharge test method based on energy storage PCS+BMS, comprising the following steps:

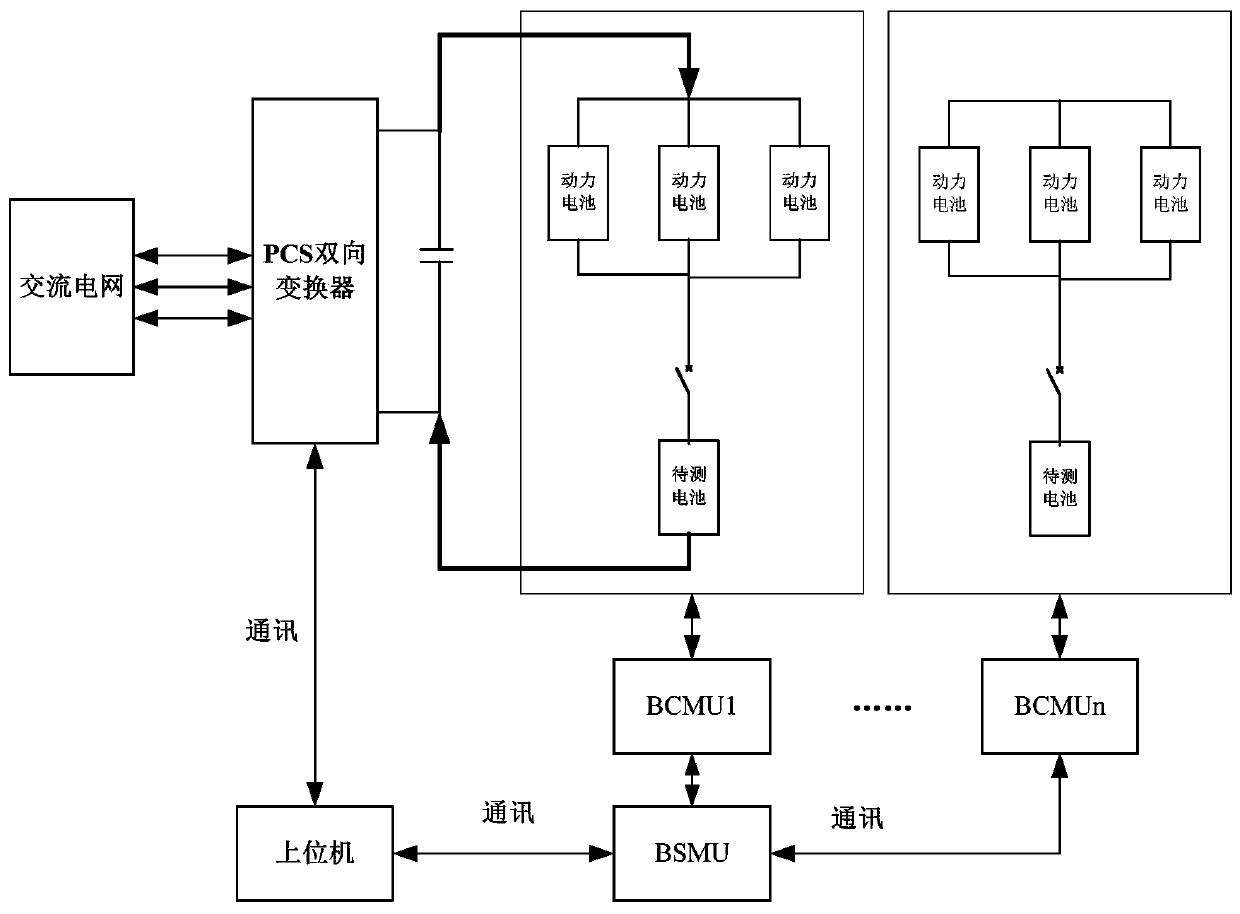

[0034] S1. Build the public DC bus required for battery charging and discharging through the energy storage PCS;

[0035] S2. When the battery is charging, the energy storage PCS extracts energy from the grid side. When the battery is discharging, the energy storage PCS feeds back the power on the DC bus to the grid;

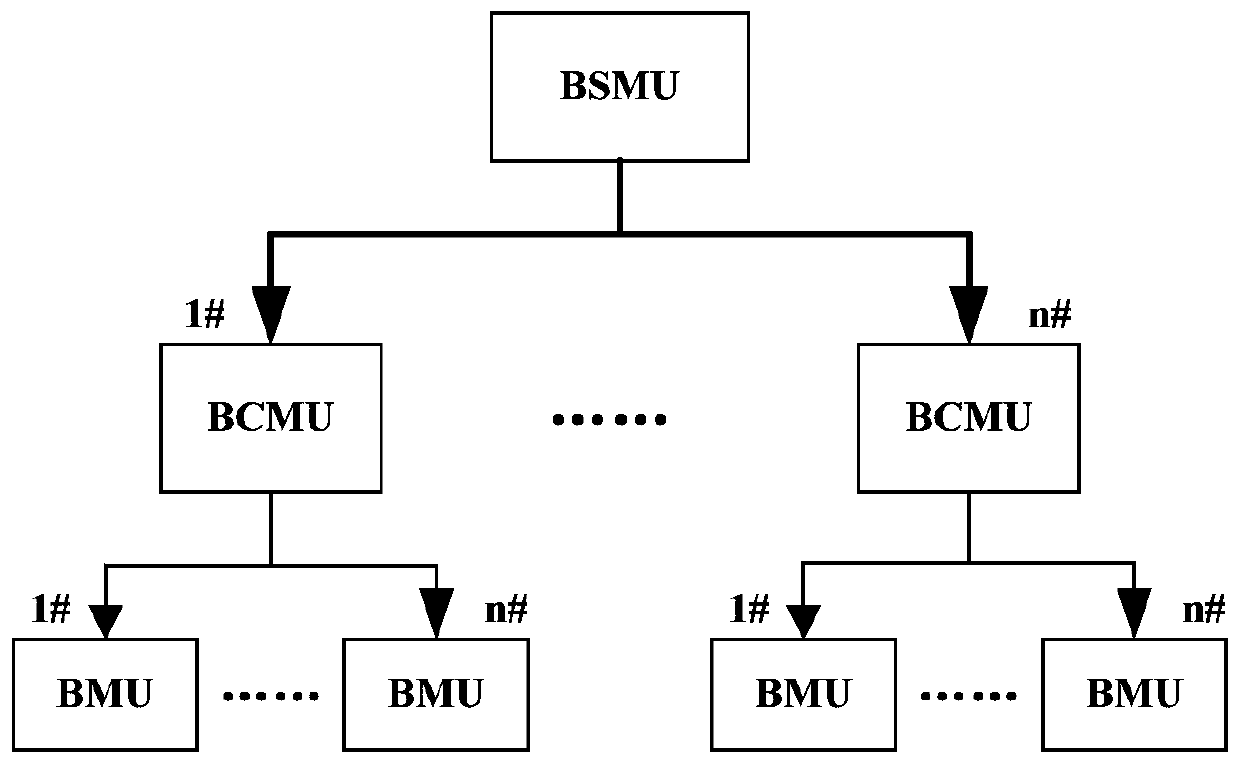

[0036] S3. The battery to be tested is connected to the DC bus, and each group of batteries to be tested is equipped with a set of BCMU. The BCMU is used to monitor the state of the battery to be tested, and to control the input and removal of the battery to be tested in the charging and discharging circuit;

[0037] S4. All the battery branches to be tested summarize the battery charge and discharge information through the BSMU, complete the battery charge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com