Ceramic body defect inspecting device and defect inspecting method

一种缺陷检查、陶瓷体的技术,应用在端面的装置领域,能够解决凹凸部分误检测为缺陷、凹凸部分易产生阴影等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

[0079]

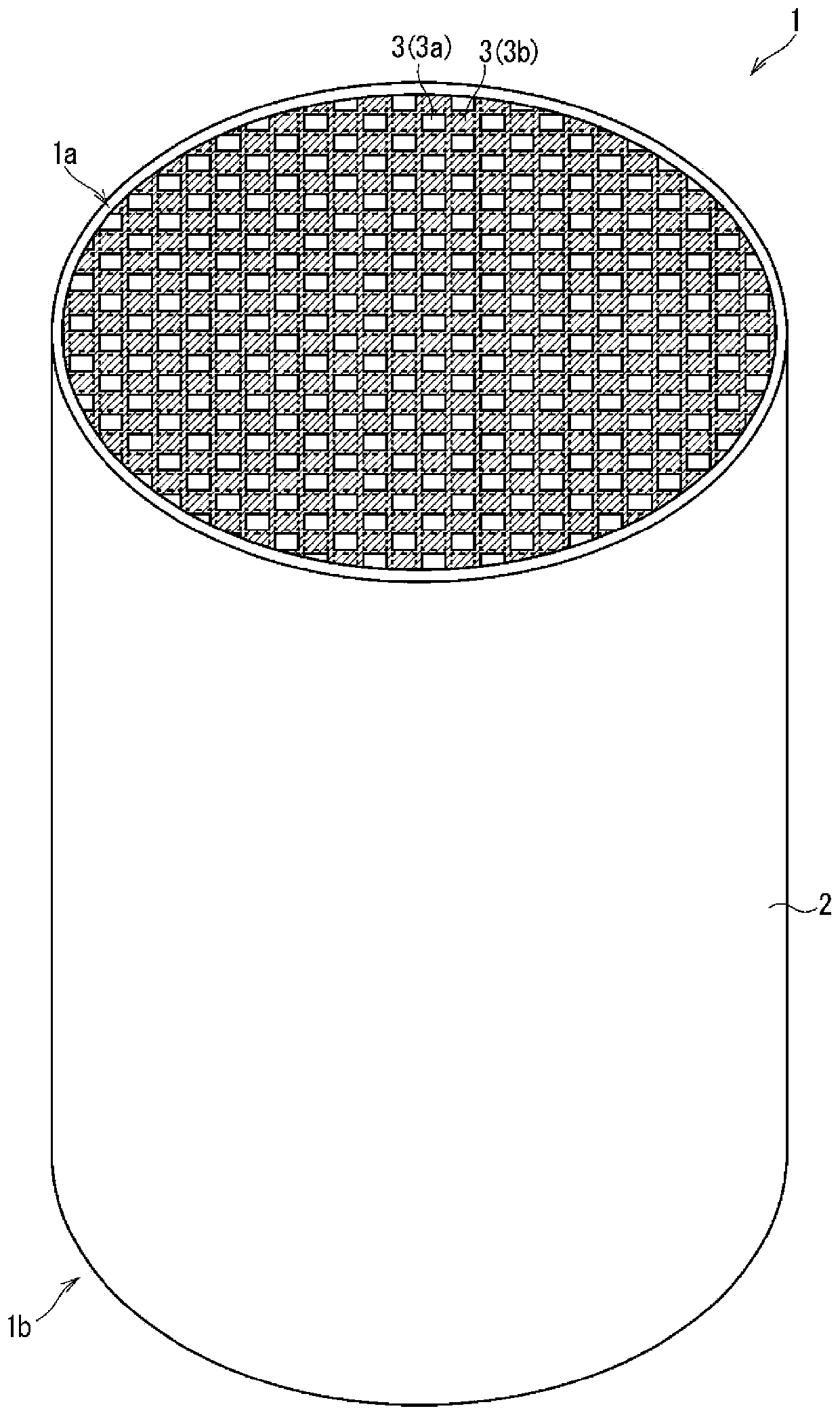

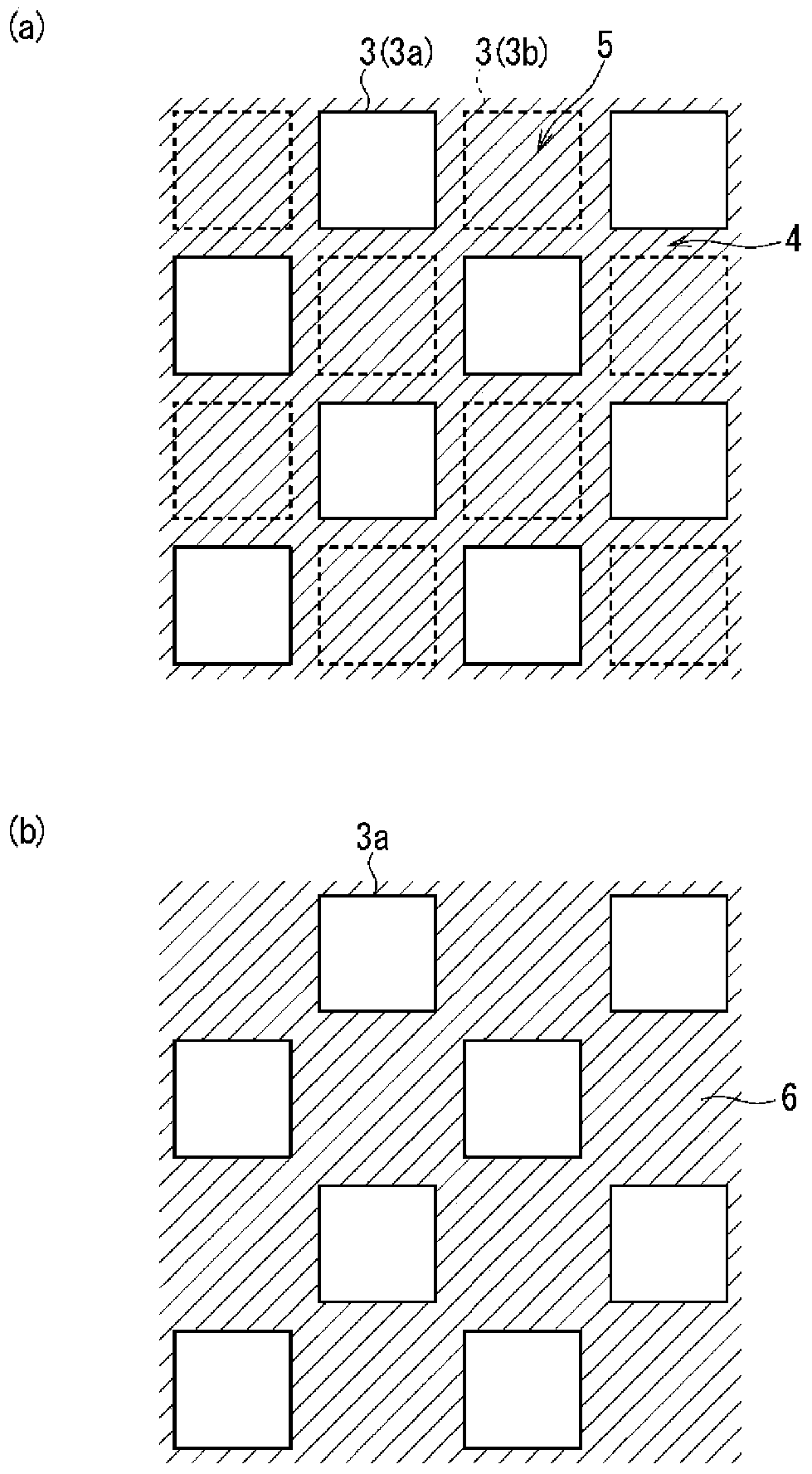

[0080] First, the honeycomb structure whose end surface is the object of defect inspection in this embodiment will be described. figure 1 It is a perspective view of the appearance of the honeycomb structure 1. figure 2 This is a partially enlarged schematic diagram of one end surface 1a of the honeycomb structure 1.

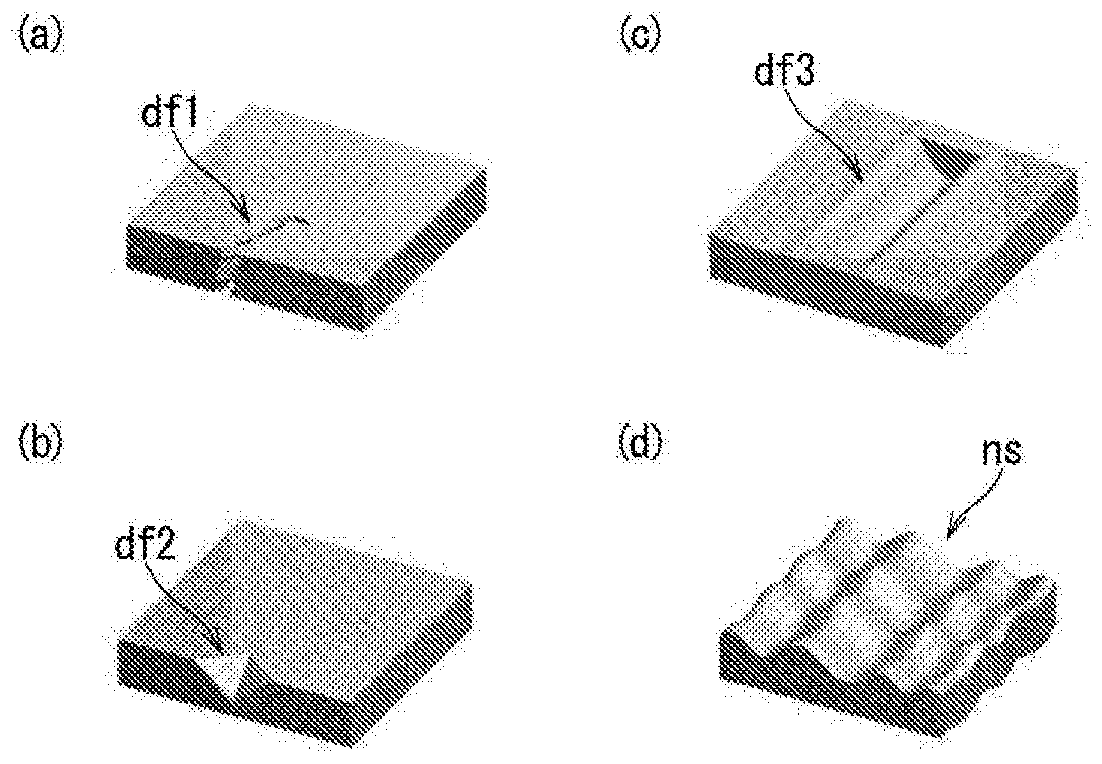

[0081] The honeycomb structure 1 is a cylindrical ceramic structure (ceramic body) having a so-called honeycomb structure inside. The honeycomb structure 1 has a plurality of cells 3 in the shape of a quadrangular prism (square in cross section) in the inside surrounded by an outer wall 2 having a cylindrical shape. Each cell 3 is divided by the partition wall 4 (refer to figure 2 (A)) is divided into sections and is along the direction (axial direction) of the central axis of the honeycomb structure 1. However, the cells 3 may be formed in an oblique prism shape whose longitudinal direction is inclined with respect to the central axis of the honeycomb s...

no. 2 approach >

[0270]

[0271] In the method of defect inspection using the defect inspection apparatus 1000 or 2000 described in the first embodiment, in principle, the size of the honeycomb structure 1 to be inspected is not limited. That is, as long as the imaging execution unit 100 (especially the first lighting unit 120 and the second lighting unit 130) of the defect inspection device 1000 or 2000 is configured to match the size of the honeycomb structure 1, no matter what size the honeycomb structure 1 is , It should be able to perform defect inspection based on the method of the first embodiment. Alternatively, even when the inspection target area is smaller than the size of the end face 1a of the honeycomb structure 1, by repeating the defect inspection multiple times while moving the inspection target area, it is possible to perform the defect inspection of the entire end face 1a.

[0272] In this case, the inspection target area becomes larger. Specifically, as the field of view (imag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com