Catalyst for nitrobenzene-to-aniline, and preparation method thereof, and method for preparing aniline

A technology for producing aniline and catalysts from nitrobenzene, which is applied in the direction of catalyst activation/preparation, preparation of amino compounds, chemical instruments and methods, etc. It can solve problems such as easy poisoning, and achieve the effects of improving service life, avoiding deactivation, and reducing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

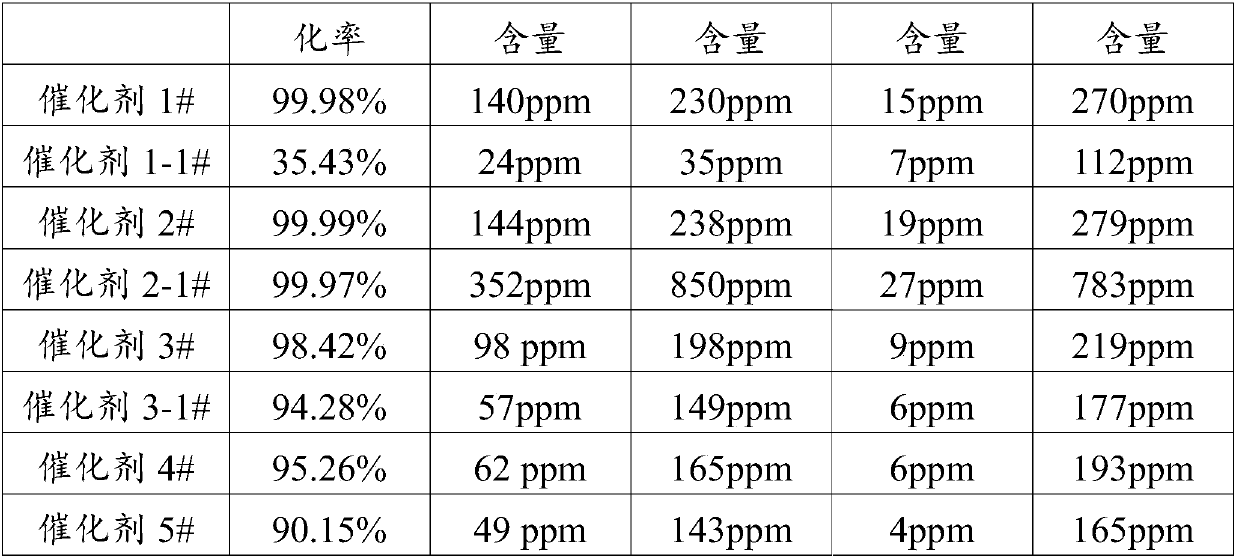

Examples

Embodiment 1

[0037] 24.5gAlCl 3 , 21.4gZn (NO 3 ) 2 Dissolve in 1L of deionized water, then add 28.1g of cetyltrimethylammonium chloride into the above salt solution, raise the temperature of the salt solution to 30°C in a water bath, adjust the pH to 8 by adding ammonia water dropwise, and form a condensation after stirring for 1 hour. The glue precipitated and aged at 90°C for 12h. Then take it out to cool, filter, and wash with a large amount of deionized water to remove the template agent to obtain a white solid powder. After that, put the solid powder in a muffle furnace and roast it, raise it to 500 °C at 1 °C / min, and continue roasting for 6 hours to further remove the template agent, and you can get mesoporous Al 2 o 3 And ZnO composite carrier. Take 0.13gH 2 PtCl 6 ·6H 2 O, 1.95gCoCl 2 ·6H 2 O, 0.64g (NH 4 ) 2 MoO 4 Dissolved in deionized water, the mesoporous Al 2 o 3 and ZnO composite carrier were added to the above salt solution, and then dried under electromagne...

Embodiment 2

[0041] 27.7gAlCl 3 , 16.4gZn (NO 3 ) 2 Dissolve in 1L of deionized water, then add 26.9g of cetyltrimethylammonium chloride to the above salt solution, raise the temperature of the salt solution to 30°C in a water bath, adjust the pH to 8 by adding ammonia water dropwise, and form a gel after stirring for 1 hour. The glue precipitated and aged at 90°C for 12h. Then take it out to cool, filter, and wash with a large amount of deionized water to remove the template agent to obtain a white solid powder. After that, put the solid powder in a muffle furnace and roast it, raise it to 500 °C at 1 °C / min, and continue roasting for 6 hours to further remove the template agent, and you can get mesoporous Al 2 o 3 And ZnO composite carrier. Take 6.1gH 2 PtCl 6 ·6H 2 O, 16.2gCoCl 2 ·6H 2 O, 5.6g (NH 4 ) 2 MoO 4 Dissolved in deionized water, the mesoporous Al 2 o 3 and ZnO composite carrier were added to the above salt solution, and then dried under electromagnetic stirring ...

Embodiment 2-1

[0043] Compared with Example 2, the difference is that the AlCl 3 and Zn(NO 3 ) 2 Zn(NO 3 ) 2 Replaced with AlCl of the same quality 3 , to obtain catalyst 2-1#, after determination, measured by BET method, its specific surface area is 189m 2 / g and the average pore diameter were 15 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com