Preparation method of white pure cerium oxide

A ceria, white technology, applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve the problems of large environmental pollution, high energy consumption, high production cost, and achieve good dispersibility and high synthesis yield. , the effect of small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

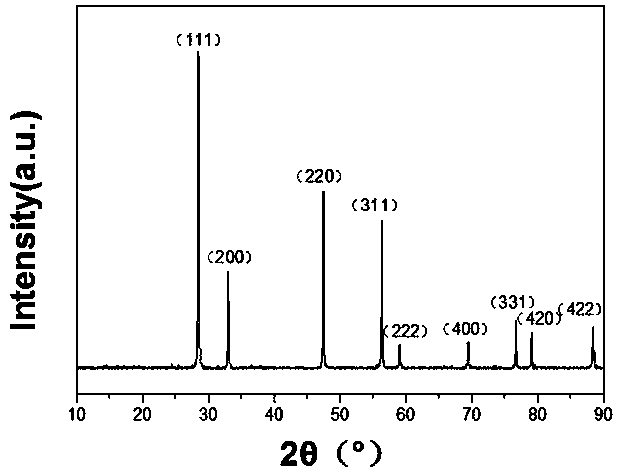

Image

Examples

Embodiment 1

[0022] A kind of preparation method of white cerium oxide, concrete steps are as follows:

[0023] (1) According to the mass volume ratio g:mL of yellow ceria and deionized water is 1:1, add yellow ceria to deionized water to obtain mixed solution A;

[0024] (2) Ultrasound the mixed liquid A in step (1) for 20 minutes and then add it into the reactor to check the airtightness of the reactor. The hydrogen pressure is 1MPa. The specific operation of the air tightness inspection is to pass 8MPa air into the reactor, and put it into the water for 20 minutes after the air is passed through. If there are no obvious bubbles on the surface, it means that the airtightness of the reactor is good, otherwise the airtightness If the performance is not good, check for air leakage;

[0025] (3) Put the reactor in step (2) into a sand bath fluid at 400°C, react for 1 hour, filter and wash after the reaction is completed, wash with deionized water and absolute ethanol for 3 times, and then p...

Embodiment 2

[0028] A kind of preparation method of white cerium oxide, concrete steps are as follows:

[0029] (1) According to the mass volume ratio g:mL of yellow ceria to deionized water is 1:1.1, add yellow ceria to deionized water to obtain mixed solution A;

[0030] (2) Ultrasound the mixed solution A in step (1) for 25 minutes and then add it into the reactor to check the airtightness of the reactor. The hydrogen pressure is 2MPa. The specific operation of the air tightness inspection is to pass 8MPa air into the reactor, and put it into the water for 20 minutes after the air is passed through. If there are no obvious bubbles on the surface, it means that the reactor is well airtight, otherwise it is airtight. If the performance is not good, check for air leakage;

[0031] (3) Put the reactor in step (2) into a sand bath fluid at 420°C and react for 0.5h. After the reaction is completed, filter and wash. The washing is to wash 4 times with deionized water and absolute ethanol, and...

Embodiment 3

[0033] A kind of preparation method of white cerium oxide, concrete steps are as follows:

[0034] (1) According to the mass volume ratio g:mL of yellow ceria and deionized water is 1:1.5, add yellow ceria to deionized water to obtain mixed solution A;

[0035] (2) Ultrasound the mixed solution A in step (1) for 40 minutes and then add it into the reactor to check the airtightness of the reactor. The hydrogen pressure is 1.5MPa. The specific operation of the air tightness inspection is to pass 8MPa air into the reactor, and put it into the water for 20 minutes after passing the air. If there are no obvious bubbles on the surface, it means that the airtightness of the reactor is good, otherwise the gas If the tightness is not good, check for air leakage;

[0036] (3) Put the reactor in step (2) into a sand bath fluid at 450°C and react for 0.5h. After the reaction is completed, filter and wash. The washing is to rinse five times with deionized water and absolute ethanol, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com