A pressure relief joint and a liquid cooling assembly using the pressure relief joint

A component and liquid cooling technology, which is applied in the direction of engine components, cooling/ventilation/heating modification, valve device, etc., can solve problems such as the inability to guarantee the sealing of liquid cooling components in the box, and the decrease of spring elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

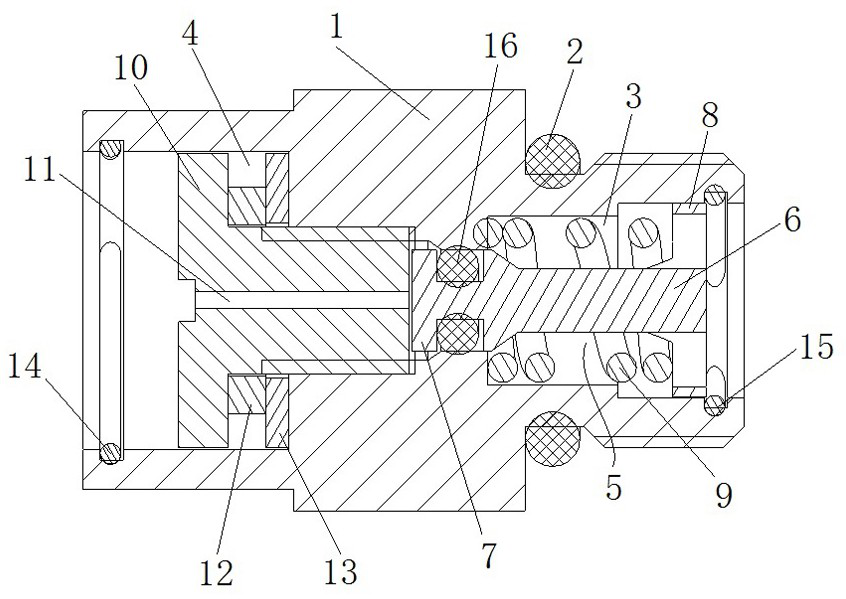

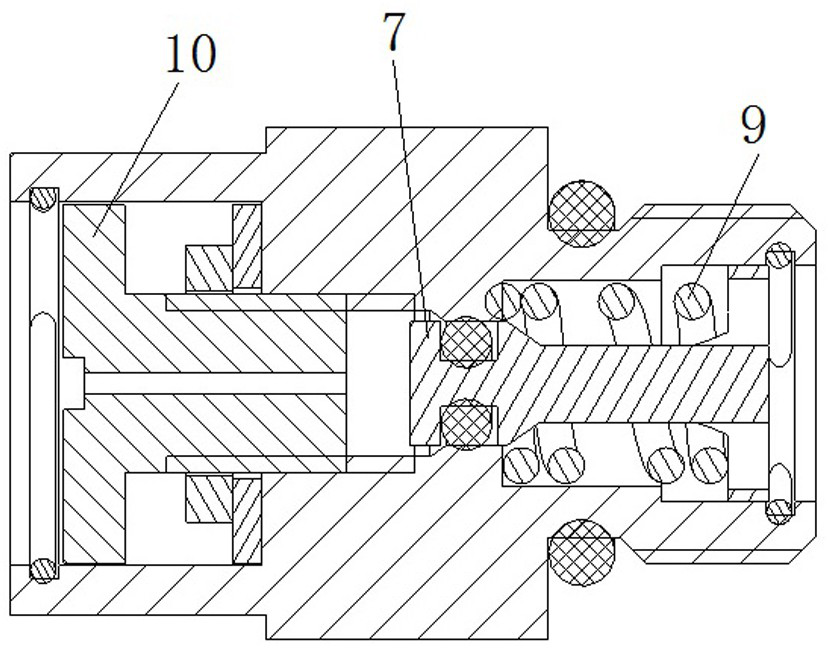

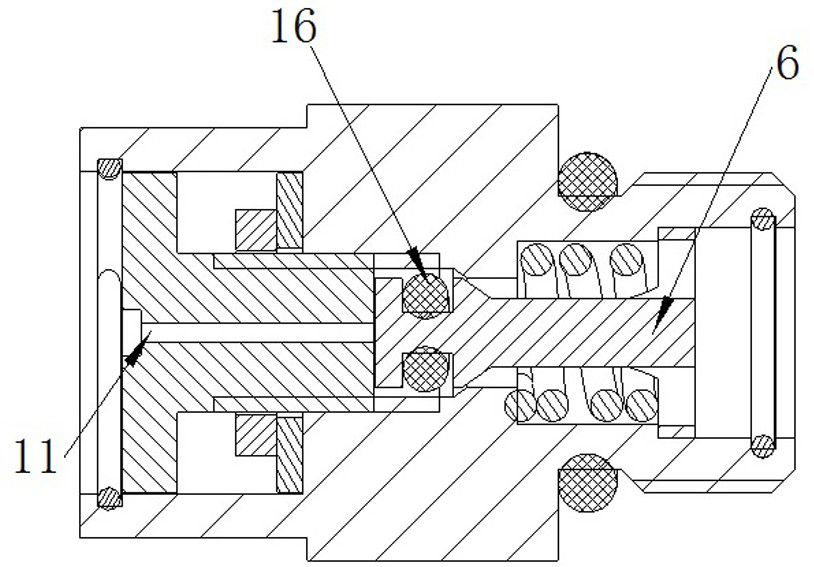

[0027] Such as Figure 1 to Figure 3 As shown, the pressure relief joint includes a joint seat 1, and the outside of the right end of the joint seat 1 along the axial direction is provided with threads for assembling on the coolant cavity, and a housing sealing ring 2 is installed on the joint seat 1 to prevent the coolant from The coolant in the cavity flows out through the pressure relief joint to ensure the airtightness of the coolant cavity.

[0028] The joint seat 1 has an axial through hole for communicating with the coolant cavity, and the axial through hole includes a valve core installation section 3 for installing a valve core and a screw installation section 4 for installing a locking screw. The spool installation section 3 includes a spring installation section with a larger aperture and a spool sealing section with a smaller aperture. A pressure relief spool 5 is installed along the axial movement guide in the spool installation section 3. The pressure relief spoo...

specific Embodiment 2

[0036] Such as Figure 4 As shown, the difference from Embodiment 1 is that in this embodiment, a blocking rod 17 is installed radially on the joint seat 1, and the way that the blocking rod 17 is assembled on the joint seat 1 can be threaded installation or other activities. way of installation. Figure 4 In the process, the blocking rod 17 and the pressure relief valve core 5 stop and cooperate to prevent the pressure relief valve core 5 from continuing to move to the left for pressure relief. When debugging or transporting the liquid-cooled component, or when the liquid-cooled component is in a high-temperature working environment, in order to prevent the pressure of the coolant inside the liquid-cooled component from increasing sharply and not being released. The retaining rod 17 is removed from the left end of the pressure relief spool 5, and the pressure relief spool 5 can perform normal pressure relief and blocking.

[0037] In this embodiment, the blocking rod 17 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com