Explosion-proof conjunction box for electric heating

An explosion-proof junction box, electric heating technology, applied in the direction of electrical components, etc., can solve the problems of heat accumulation and future maintenance difficulties, small wiring area, difficult to operate, short service life, etc., to achieve simple and reasonable structure, simple assembly, and easy manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

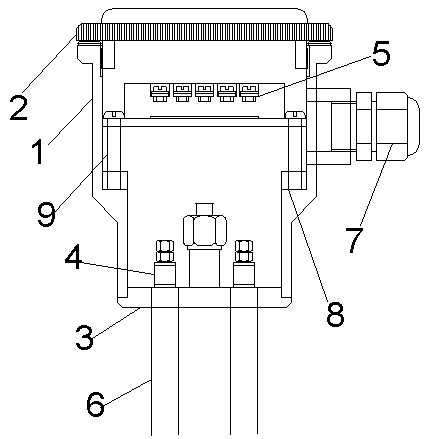

[0011] Such as figure 1 As shown, an explosion-proof junction box for electric heating, the explosion-proof junction box includes a cylindrical shell 1 with a cavity, an end cover 2 on the top of the cylindrical shell, a flange 3 is provided at the bottom of the explosion-proof junction box, The flange plate is provided with a connecting post 4 for connecting the electric heating tube; the explosion-proof junction box is provided with a connecting line terminal row 5, and the bottom of the flange plate is connected with an insulating sleeve 6, and the terminal post of the power supply heating tube is inserted through, so The explosion-proof junction box is provided with a cable inlet clamping head 7; the cylindrical shell is provided with a boss 8, and the connecting wire terminal row is installed on the boss through bolts 9.

[0012] The insulation sleeve is welded and sealed with the flange.

[0013] The explosion-proof junction box is made of 304 or 316L stainless steel. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com