Method for preparing fat substitute by using cassava starch to regulate and control oil drop accumulation in emulsion

A fat substitute, cassava starch technology, applied in food science and other fields, can solve the problems of low-fat food audience acceptance and commercial success rate limitations, changes, and unsatisfactory problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

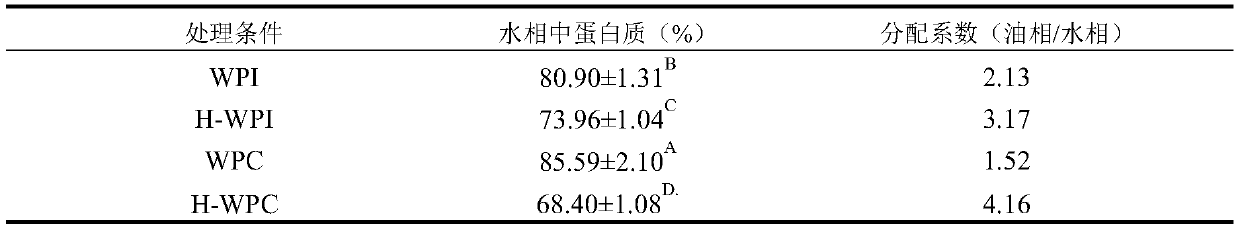

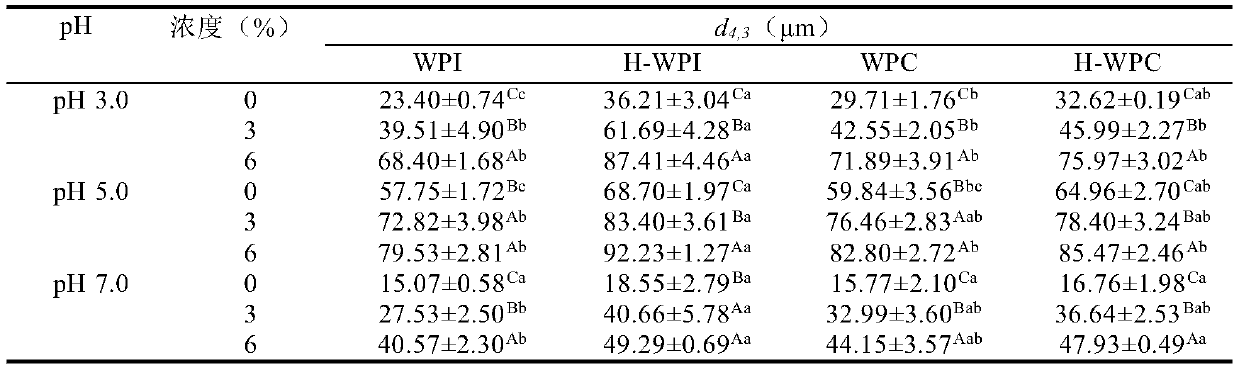

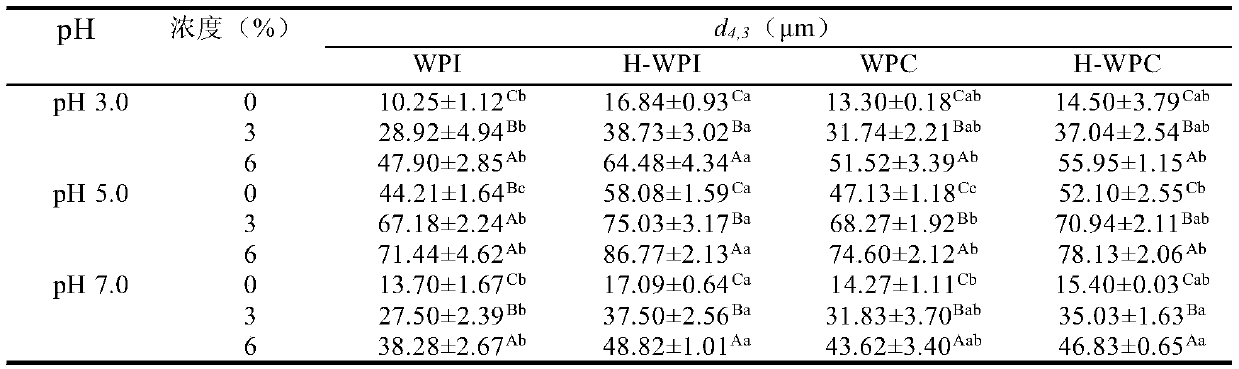

[0008] Embodiment 1: Step 1. Weigh a certain amount of whey protein isolate (WPI) powder and disperse it in deionized water. Stir it with a magnetic stirrer at room temperature for at least 1 hour to fully dissolve it, and prepare it into 4% (w / v ) protein dispersion. The WPI protein dispersion was divided into two equal volumes, one of which was heated in a water bath at 90°C for 5 minutes, and then quickly cooled to room temperature after being taken out, which was expressed as Pre-heated whey protein isolate (H-WPI ). Whey protein concentrate (WPC) and pre-heated whey protein concentrate (Pre-heated wheyproteinconcentrate, H-WPC) dispersion were prepared by the same method. Mix 90 mL of these four protein dispersions with 10 mL of rapeseed oil respectively, and use an Ultra-Turrax homogenizer to homogenize at 13,500 rpm for 2 min to obtain a coarse emulsion. The obtained coarse emulsion was homogenized under the condition of 40 MPa, and the homogeneous liquid (fresh emuls...

specific Embodiment approach 2

[0009] 1. Embodiment two: the difference between this embodiment and embodiment one is that the cassava modified starch concentration is 0, 1.5, 3, 4.5, 6%, w / v in the cassava modified starch-emulsion mixture.

specific Embodiment approach 3

[0010] 2. Specific embodiment three: the difference between this embodiment and specific embodiment one is that tapioca modified starch concentration is 0,1.5,3,4.5,6% in cassava modified starch-linseed gum (0.01%, w / v) mixture , w / v.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com