Remote control car with simple servo control system

A servo control system, a technology for remote control cars, applied in the field of remote control cars, can solve problems such as the gap between the motor speed and the expected speed, inaccurate control speed, vehicle body offset, jumping, etc., to achieve accurate speed regulation, saving quantity, and twisting small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

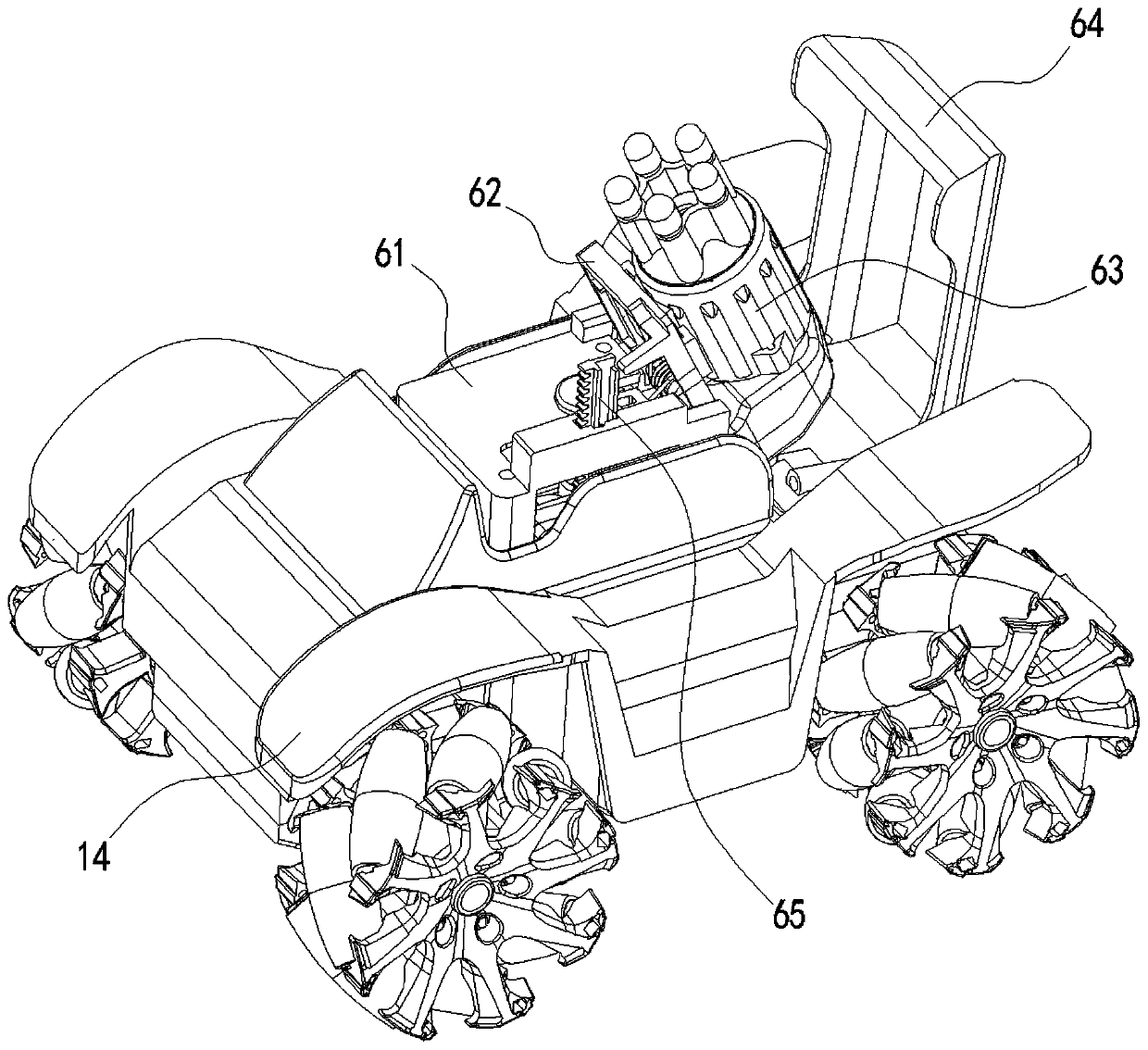

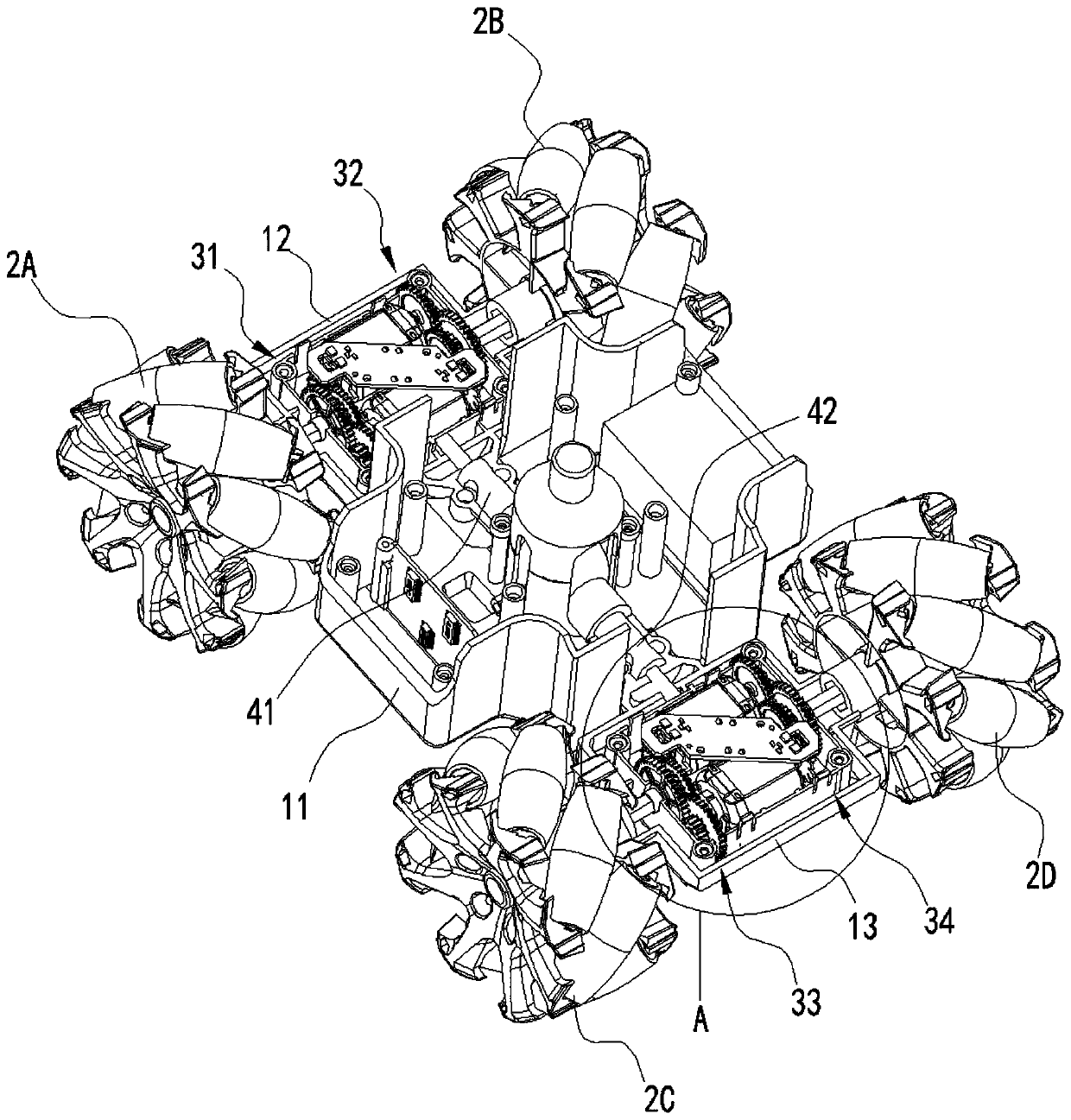

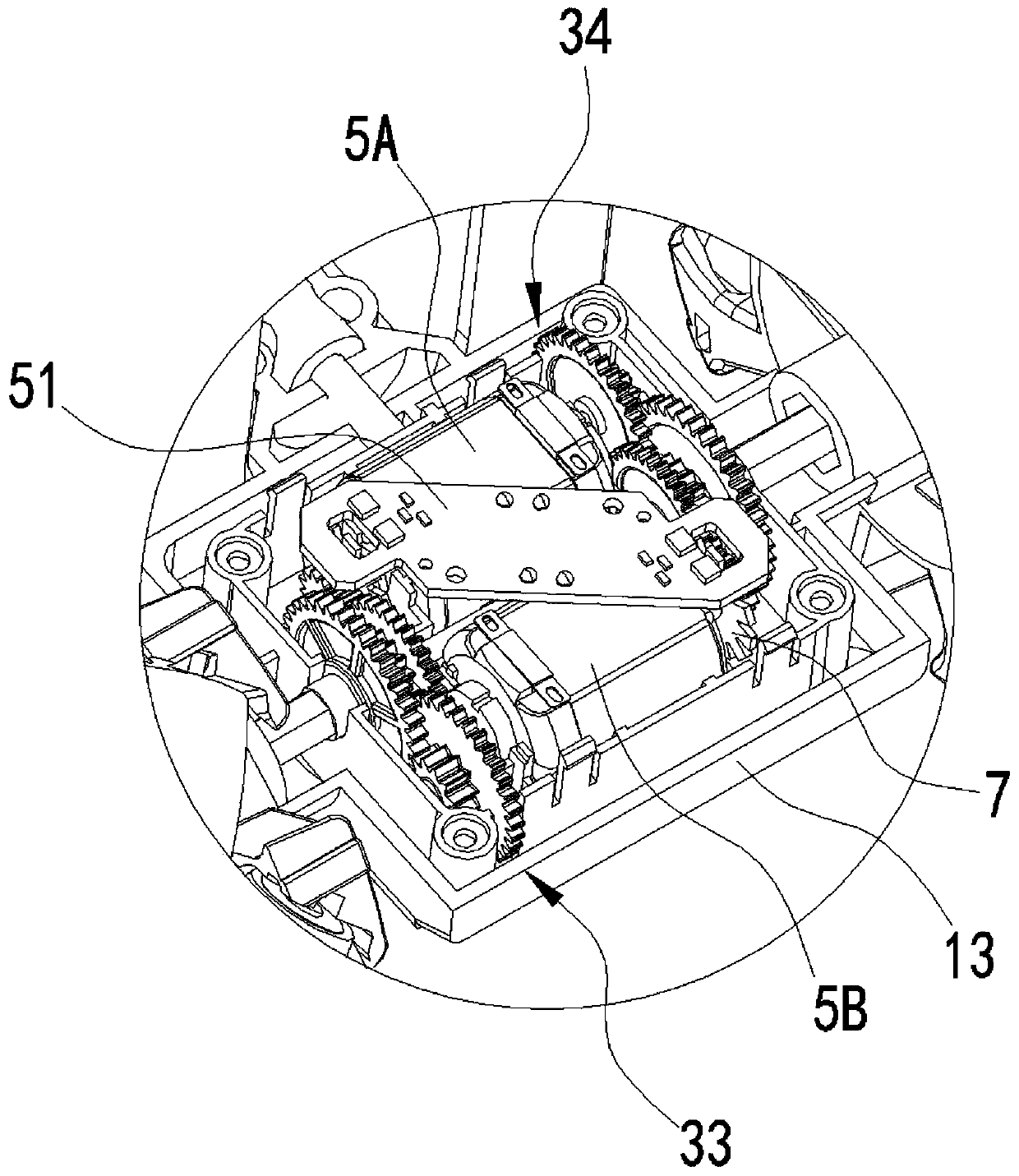

[0045] In order to make the purpose of the present invention, technical solutions and advantages clearer, the following will combine figure 1 - Figure 12 The accompanying drawings describe the present invention in further detail.

[0046] refer to figure 1 - Figure 12 As shown, a remote control car with a simple servo control system includes a vehicle body, a driving wheel that is rotated on the vehicle body, a reduction gear set that is installed in the vehicle body and is connected to the drive wheel, and a reduction gear set that is installed in the vehicle body and connected The motor connected by the transmission, when the motor is energized and rotates at high speed, the linkage reduction gear set rotates, and the reduction gear set converts the rotation of the motor at high speed and low torque into the rotation of low speed and high torque, and then the linkage drive wheel rotates.

[0047] The vehicle body can be an integral fixed vehicle body or a split type veh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com