Efficient reaction kettle with convenient sampling function

A reactor and high-efficiency technology, applied in the field of high-efficiency reactors, can solve problems such as inability to collect sample liquids, achieve good mixing effects, facilitate sampling operations, and facilitate discharge effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

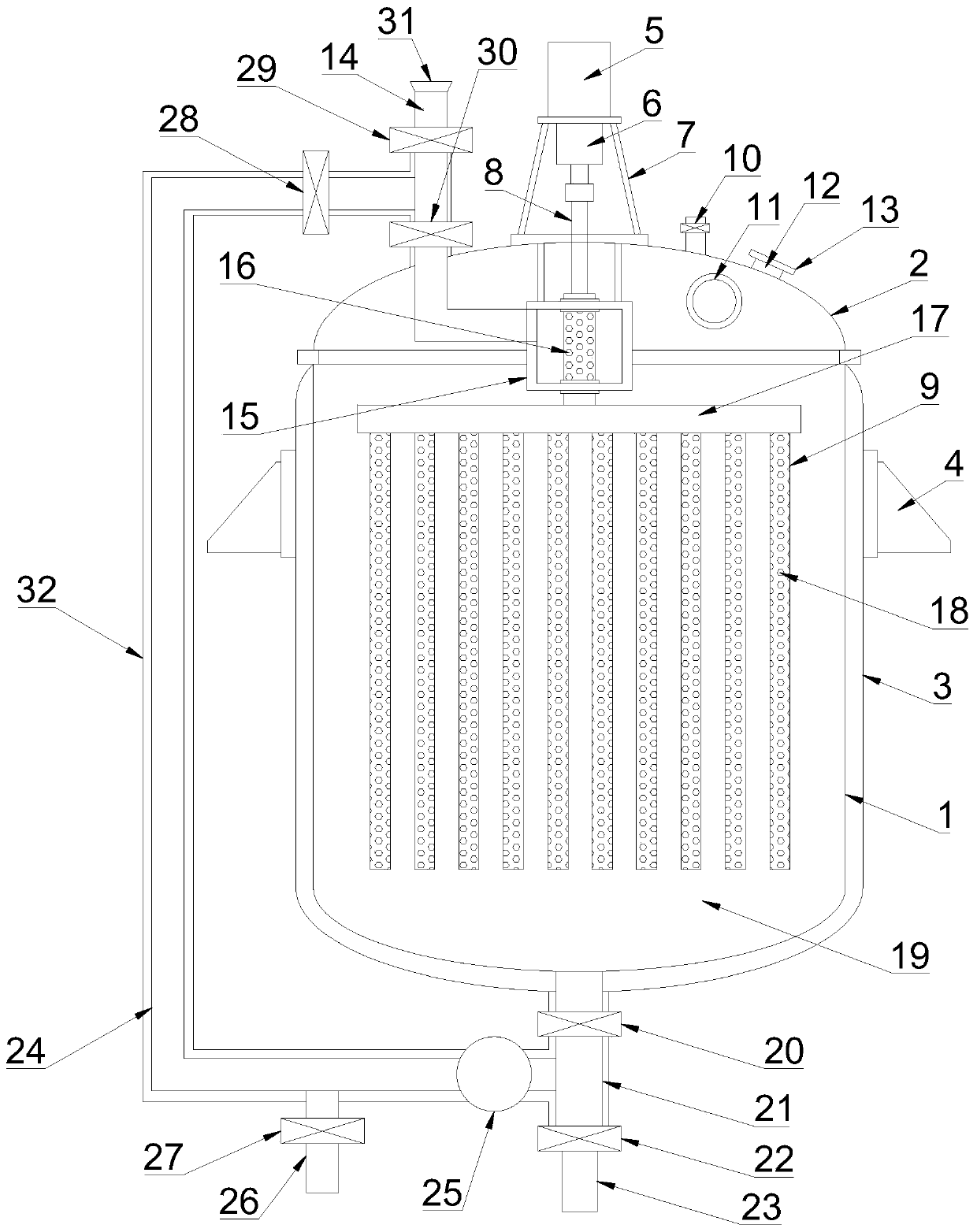

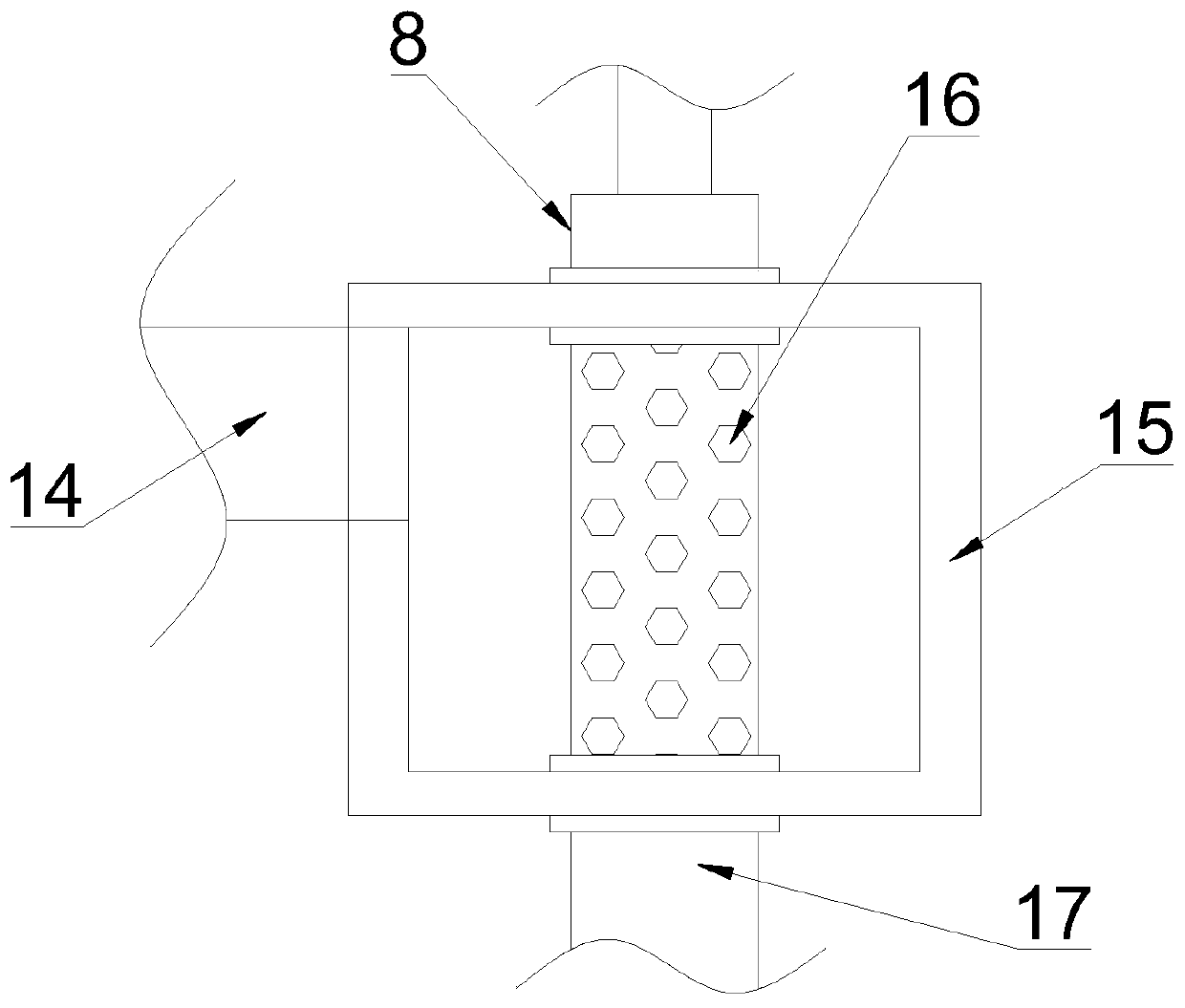

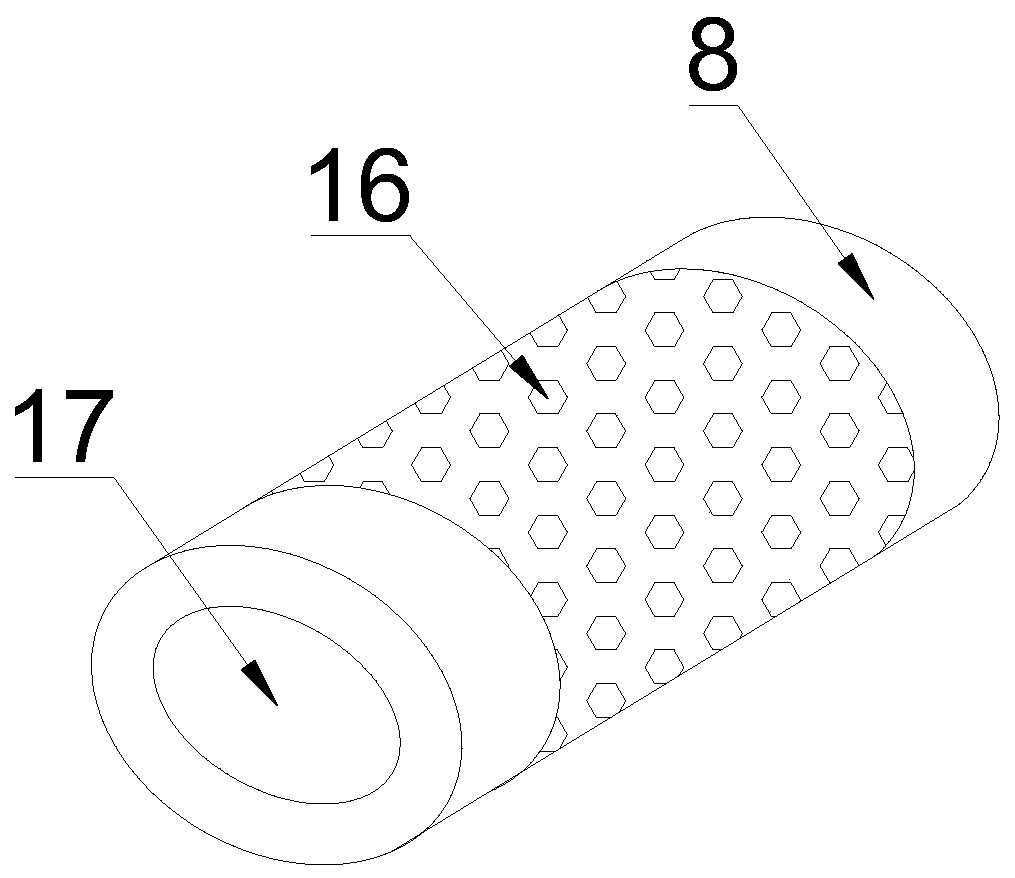

[0028] see Figure 1 ~ Figure 3 , a high-efficiency reactor for convenient sampling, comprising a reactor body 1 and a reactor cover 2, the reactor body 1 is connected to the reactor cover 2 to form reactor equipment, and the reactor body 1 is provided with an insulating layer 3 for use To insulate the reactor body 1 to reduce heat loss; preferably, in the embodiment of the present invention, heating devices and / or cooling devices can also be installed in the insulation layer 3, and the heating devices include but are not limited to known electric heating , steam heating and other heating devices, cooling devices include but are not limited to known cooling devices or devices such as water cooling or air cooling, so as to achieve heat preservation and also facilitate the adjustment of the temperature of the reactor body 1 .

[0029] The top of the reaction kettle cover 2 is welded with a frame 7, and a motor 5 is installed on the frame 7. The motor 5 is connected to the reduce...

Embodiment 2

[0042] A high-efficiency reactor for convenient sampling, including a reactor body 1 and a reactor cover 2, the bottom of the reactor body 1 is connected to a drain pipe 21, and the return pipe 24 connected to the drain pipe 21 is arranged on the insulation layer outside the reactor body 1 3, the top of the return pipe 24 is connected to the liquid inlet pipe 14, and the circulating pump 25 and the sampling pipe 26 connected to the return pipe 24 are still arranged outside the reaction kettle body 1. Such a setting can save the setting of the heat preservation jacket 32 on the return pipe 24 ,cut costs.

[0043] The rest of the structure of this embodiment 2 is the same as that of embodiment 1.

Embodiment 3

[0045] see Figure 4 As shown, a high-efficiency reactor for convenient sampling includes a reactor body 1 and a reactor cover 2, the bottom of the reactor body 1 is connected to a drain pipe 21, and the return pipe 24 connected to the drain pipe 21 is directly connected to the inside of the reactor body 1. The reaction chamber 19 is connected, and the extracted material liquid can be directly returned to the reaction chamber 19, and the circulation flow efficiency is higher; at the same time, the installation of the fourth solenoid valve 28 and the sixth solenoid valve 30 can be reduced.

[0046] Further, the return nozzle of the return pipe 24 is arranged along the tangential direction of the inner wall of the reaction kettle body 1, and the feed liquid flowing back to the reaction chamber 19 flows in a vortex shape along the inner wall of the reaction kettle body 1, and with the agitation of the stirring rod 9, the mixing effect is improved. better.

[0047] The rest of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com