Liquid crystal display panel line laser cutting machine

A liquid crystal panel and cutting machine technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of high equipment cost, fragile products, high raw material cost, etc., and achieve low equipment investment cost, intelligent and simple operation, The effect of low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

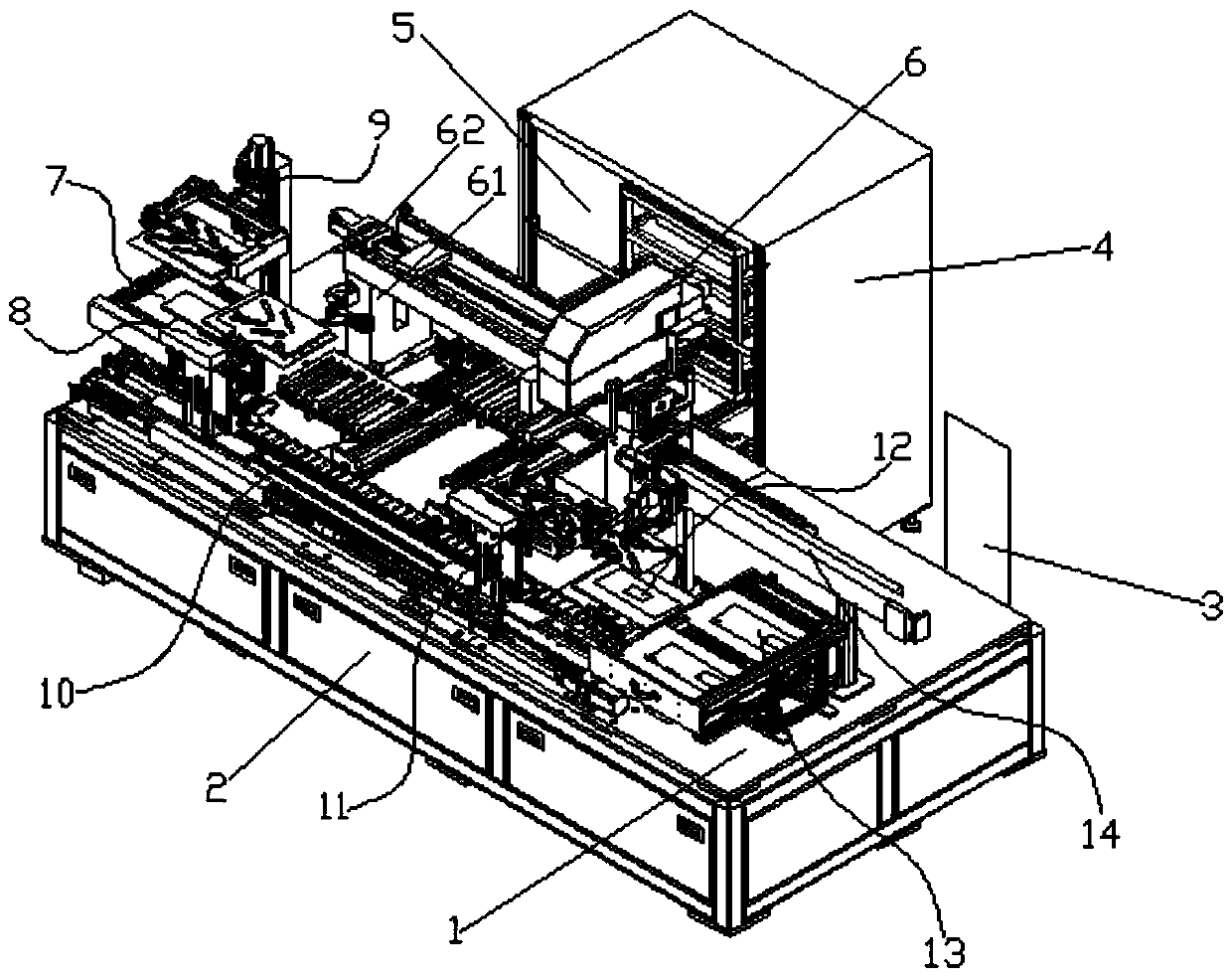

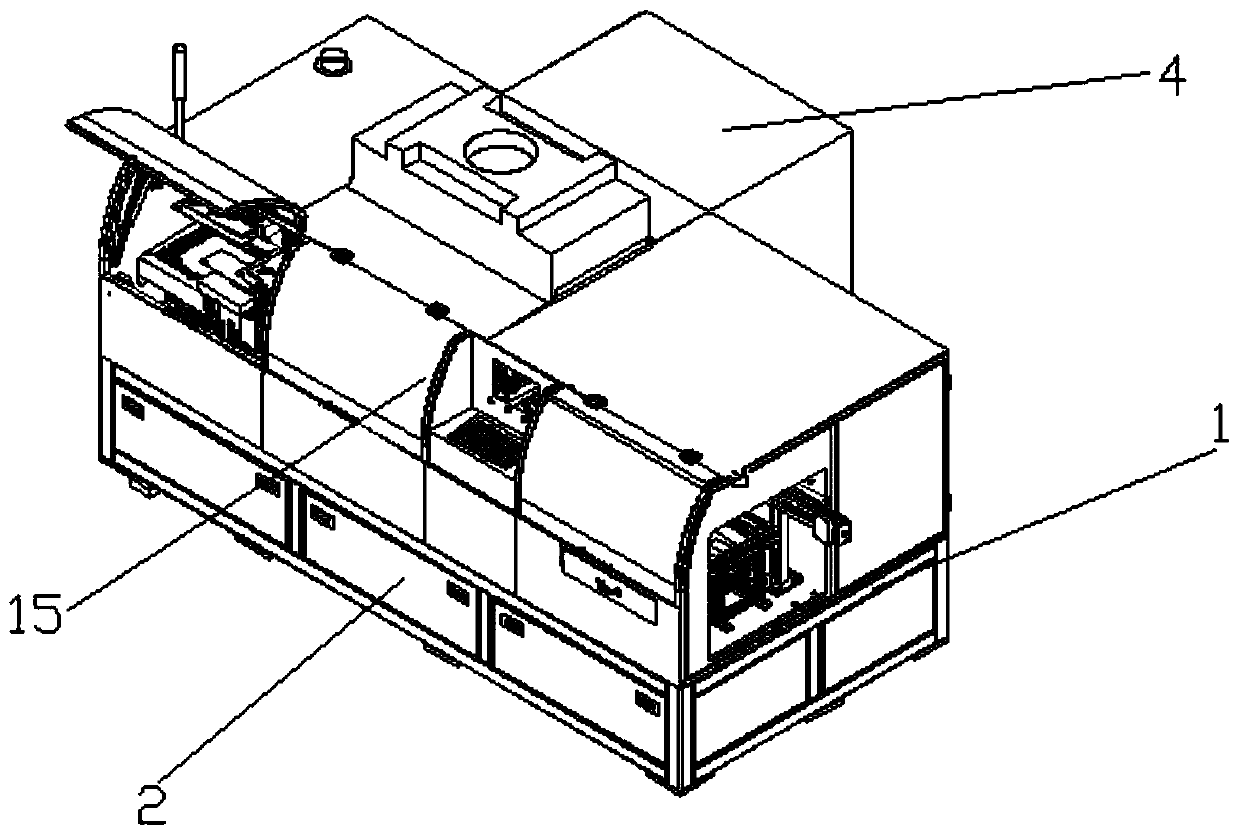

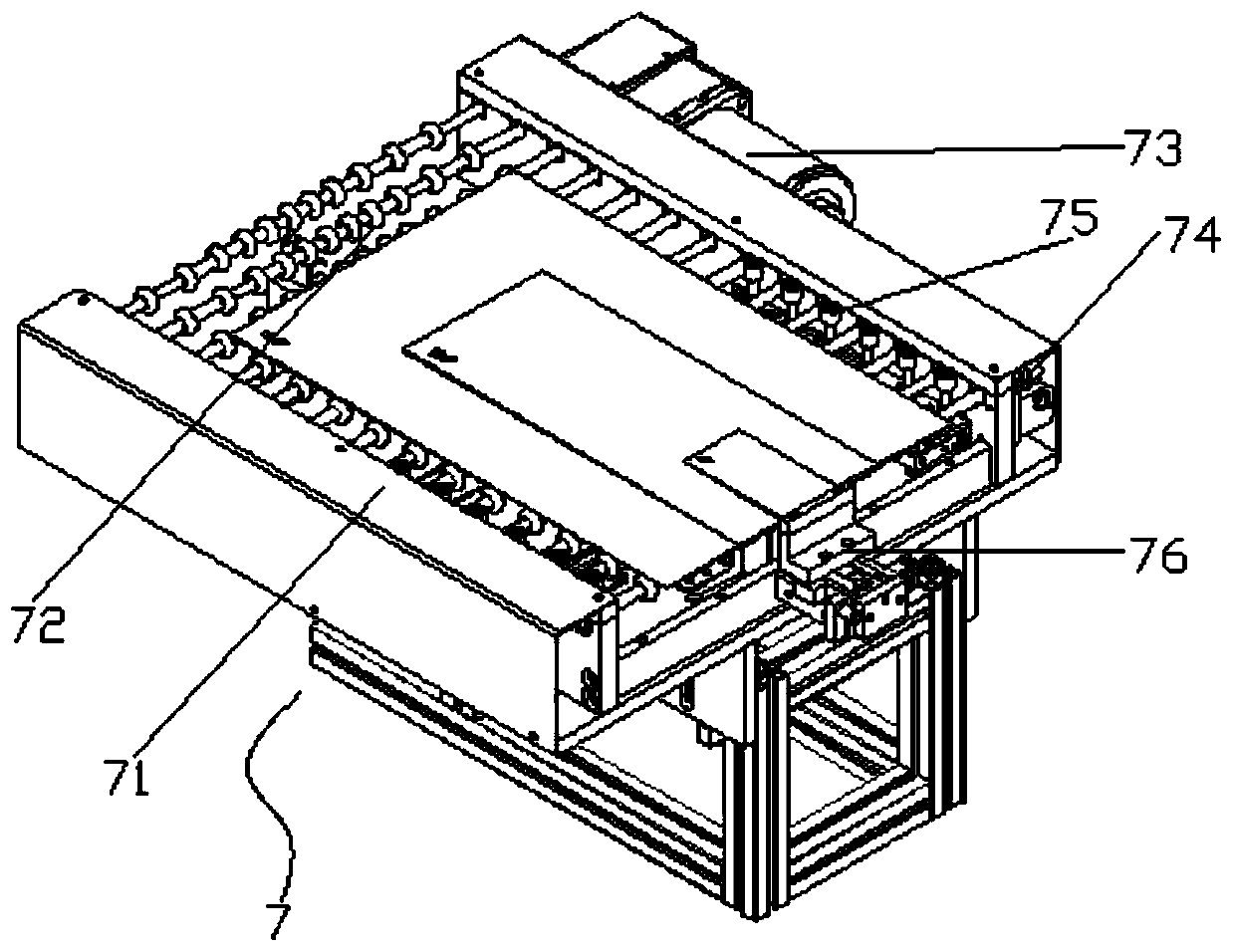

[0026] see figure 1 , a liquid crystal panel line laser cutting machine, including a frame 1, an electric control box 2, a man-machine interface 3, a laser generator box 4, an industrial computer 5, a laser head 6, a material receiving mechanism 7, a material feeding mechanism 8, Flipping mechanism 9, laser stage mechanism 10, unloading mechanism 11, transfer platform 12, NG slice module 13 and discharging mechanism 14, described electric control box 2 is arranged at the bottom of frame 1, and electric control box is used for all The electric equipment performs circuit control, the man-machine interface 3 is set on the side of the frame 1, the man-machine interface sets and adjusts the parameters of the servo motor and the cylinder, and the laser generator box 4 is equipped with a red laser generator. laser generator and a green laser genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com