Composite welding method for different-strength jointed connectors of Q370qE and Q690qE bridge structural steel

A q690qe, composite welding technology, applied in the field of steel bridge manufacturing, can solve the problems of great difficulty, large welding deformation, insufficient welding strength, etc., to achieve the advantages of control, reduce the cross-sectional area of the weld, and ensure operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

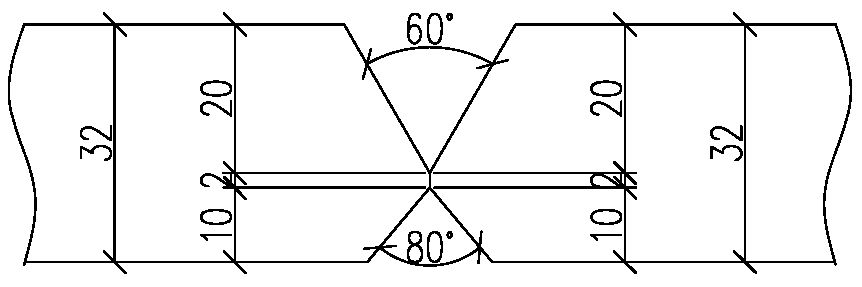

[0055] The thickness of the welded steel plate is 32mm, and the materials are Q370qE and Q690qE respectively. Follow the steps below when welding:

[0056] (1) if figure 1 The schematic diagram of the opposite groove structure is shown, the groove is processed on both sides of the two steel plates, and the two sides of the groove are X-shaped as a whole; The groove forms an included angle of 60° as a whole, the large-angle groove angle on the other side is 40°, the large-angle groove between the two steel plates forms an included angle of 80° overall, and the blunt side is 2mm; the small-angle slope The ratio of the depth of the groove to the depth of the large-angle groove is 2:1, the depth of the small-angle groove is 20mm, and the depth of the large-angle groove is 10mm.

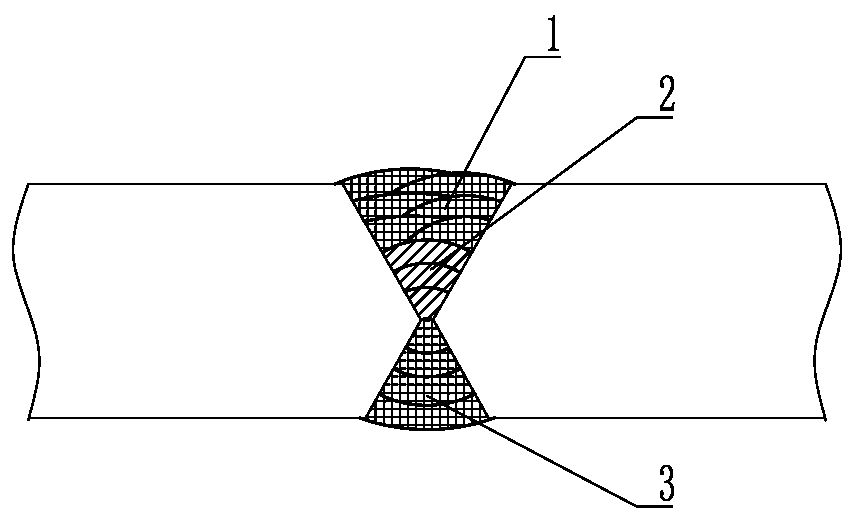

[0057] (2) Electromagnetic induction heating equipment is used to heat before welding, and the heating temperature is 70-80°C, such as figure 2 As shown, first use gas shielded welding to weld 3 backin...

Embodiment 2

[0090] The composite welding method of spliced joints with different strengths for Q370qE and Q690qE bridge structural steels with a plate thickness of 50 mm, includes the following steps in sequence:

[0091] (1) Groove is processed on both sides at the joint of two steel plates made of Q370qE and Q690qE respectively. The mouth angle is 41 °, and the blunt edge is 2.5mm; the depth ratio of the small-angle groove and the large-angle groove is 2.5:1;

[0092] (2) First use gas shielded welding to weld 3 times on the side of the small-angle groove to form a bottom weld, and preheat the steel plate to 70-80°C before welding;

[0093] (3) After the bottoming weld is completed, the welding heat raises the temperature of the steel plate to 115-155°C, and the welding groove is fully welded by submerged arc automatic welding on the same side of the small-angle groove, and the welding heat input is controlled at 30-35KJ / cm, using multi-layer and multi-pass welding method for weldin...

Embodiment 3

[0125] The composite welding method of spliced joints with different strengths for Q370qE and Q690qE bridge structural steels with a plate thickness of 50 mm, includes the following steps in sequence:

[0126] (1) Groove is processed on both sides at the joint of two steel plates made of Q370qE and Q690qE respectively. The double sides of the groove are X-shaped as a whole; The angle of the large-angle groove is 39°~41°, and the blunt edge is 2.5mm; the depth ratio of the small-angle groove to the depth of the large-angle groove is 2.5:1;

[0127] (2) First use gas shielded welding to weld 3 times on the side of the small-angle groove to form a bottom weld, and preheat the steel plate to 70-80°C before welding;

[0128] (3) After the bottoming weld is completed, the welding heat raises the temperature of the steel plate to 115-155°C, and the welding groove is fully welded by submerged arc automatic welding on the same side of the small-angle groove, and the welding heat inpu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com