A New Automobile Chassis Quick Change Robot Welding Station

A technology for robot welding and automobile chassis, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of long replacement time and low efficiency of products to be welded, and achieve space saving, fast replacement, and precision. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

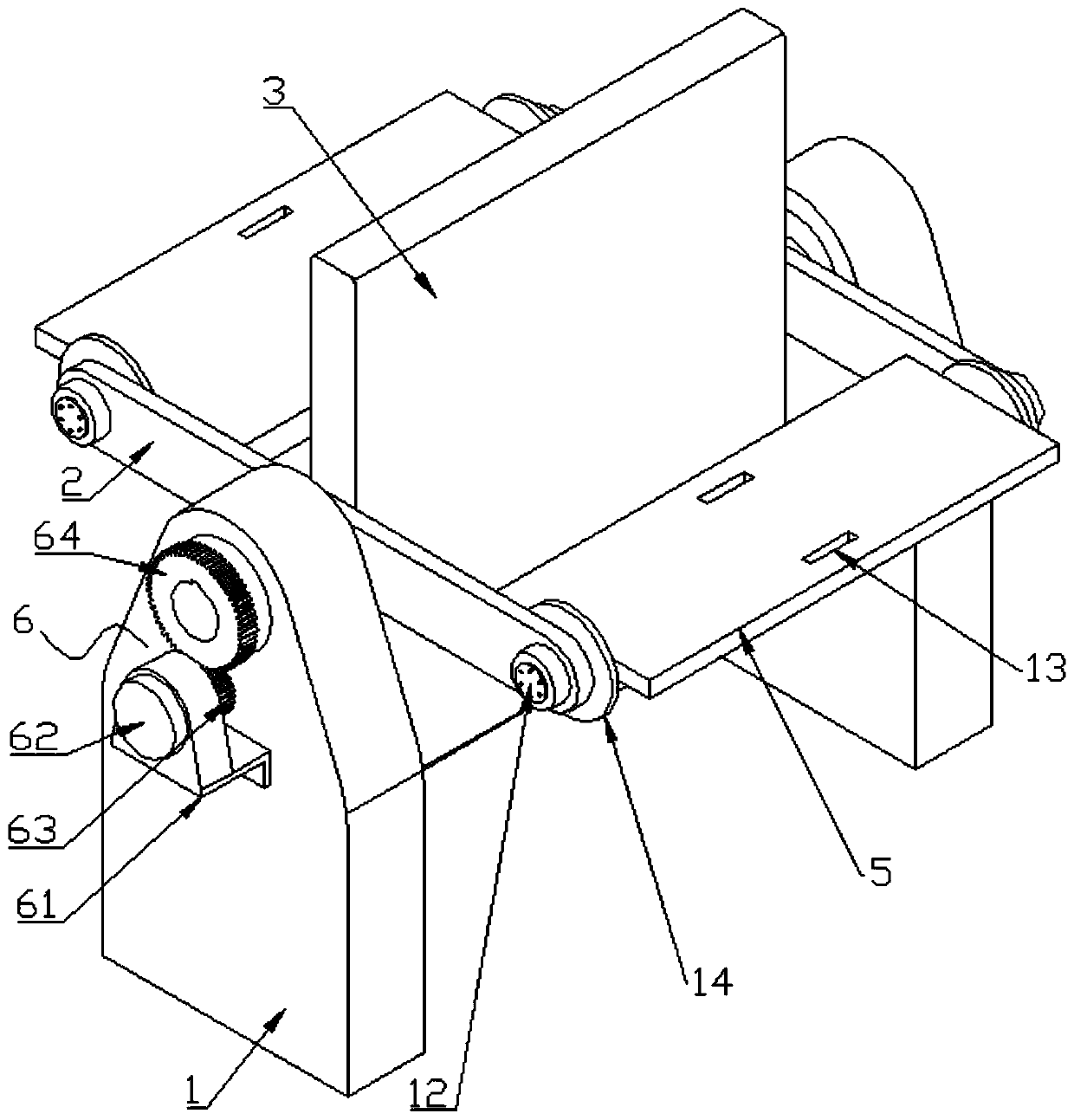

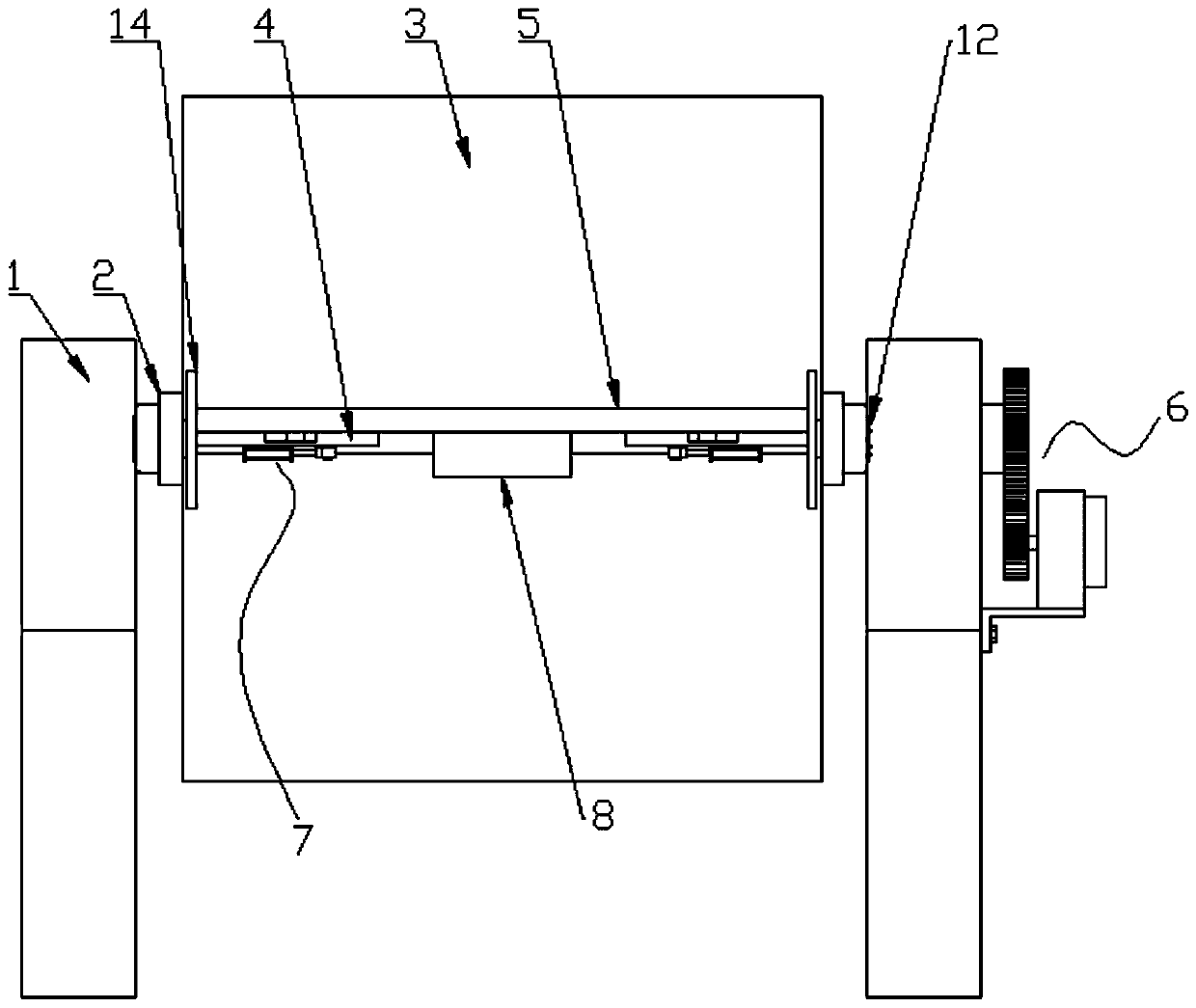

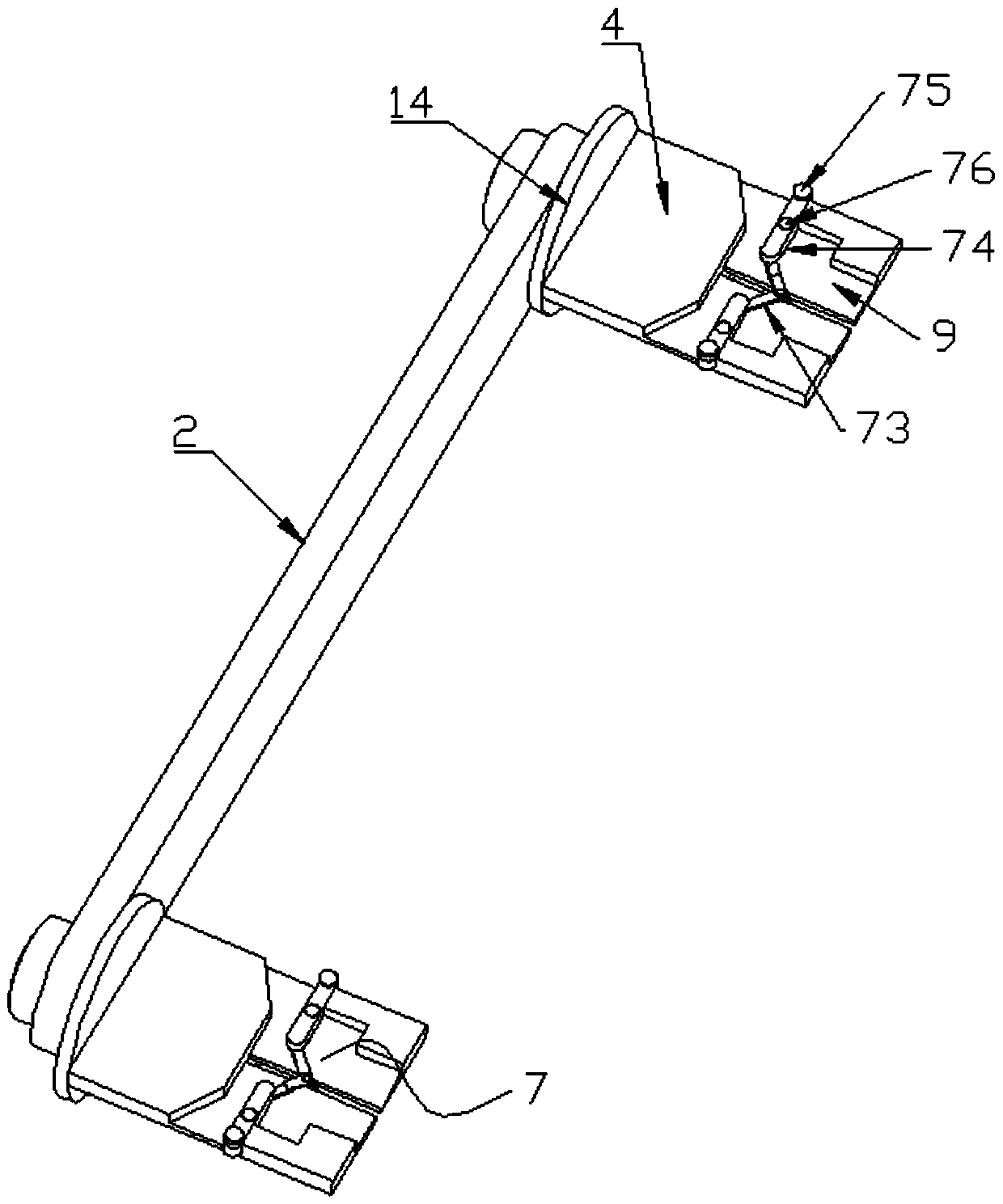

[0030] like Figure 1 to Figure 6 As shown, a new type of automobile chassis quick-change robot welding station includes a machine base 1, a rotary bracket 2, a partition 3, a support platform 4 and a clamp 5, and the said machine base 1 has two and is arranged symmetrically, and the said rotary bracket One end of 2 is rotatably connected to the base 1 through a bearing, and a drive assembly 6 is installed on one of the base 1 and can drive the slewing bracket 2 to rotate 360 degrees. The two ends of the slewing bracket 2 are also rotatably connected to the The support platform 4, a circular plate 14 is also connected between the support platform 4 and the rotary support 2, perpendicular to the support platform 4, used to separate the support platform 4 from the rotary support 2, and also play the role of the clamp 5 The function of positioning, a locking mechanism 7 is installed on the support platform 4, the clamp 5 is arranged on the support platform 4 and locked and posi...

Embodiment 2

[0038] like Figure 7 As shown, a new type of automobile chassis quick-change robot welding station includes a machine base 1, a rotary bracket 2, a partition 3, a support platform 4 and a clamp 5, and the said machine base 1 has two and is arranged symmetrically, and the said rotary bracket One end of 2 is rotatably connected to the base 1 through a bearing, and a drive assembly 6 is installed on one of the base 1 and can drive the slewing bracket 2 to rotate 360 degrees. The two ends of the slewing bracket 2 are also rotatably connected to the A support platform 4, a circular plate 14 is also connected between the support platform 4 and the rotary support 2, perpendicular to the support platform 4, used to separate the support platform 4 from the rotary support 2, and also play the role of the clamp 5 The function of positioning, a locking mechanism 7 is installed on the support platform 4, the clamp 5 is arranged on the support platform 4 and locked and positioned by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com