High-temperature fuel cell graphite bipolar plate stamping molding mold and method

A high-temperature fuel cell and stamping forming technology, applied in the field of high-temperature fuel cells, can solve the problems of affecting the performance and life of the fuel cell stack, destroying the surface structure of the graphite plate, rough and burr on the surface of the finished product, etc., so as to speed up the commercialization process and solve the problem of surface Corrosion and hydrogen permeation, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

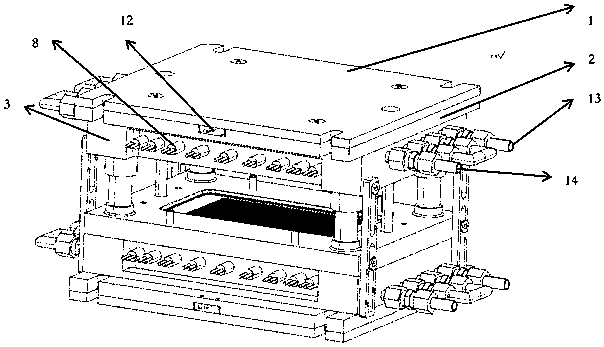

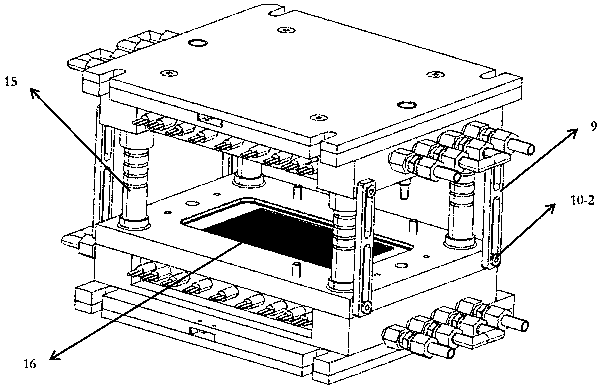

[0042] The installation of embodiment 1 mold

[0043] Fasten the thermal resistance upper plate 2 and the upper cover plate 1 of the mold to the upper end plate of the hydraulic press through four positioning hole bolts, and the upper mold 19 and the four corners of the heating and cooling plate 3 are used to fasten the heating and cooling upper plate. The plate 3 is fixed on the upper cover plate 1, so that the heating and cooling plate 3, the thermal resistance upper plate 2, and the upper cover plate 1 are fastened together by bolts and fixed with the upper end plate of the hydraulic press. The cooling water inlet 13 and the cooling water outlet 14 are respectively connected with stainless steel water pipes for the entry and exit of mold cooling circulating water.

[0044]The upper surface of the thermal resistance upper plate 2 is provided with a thermal resistance threading hole 20 and a thermal resistance threading groove 21, and two thermal resistances 18 pass through t...

Embodiment 2

[0049] Embodiment 2 molding process

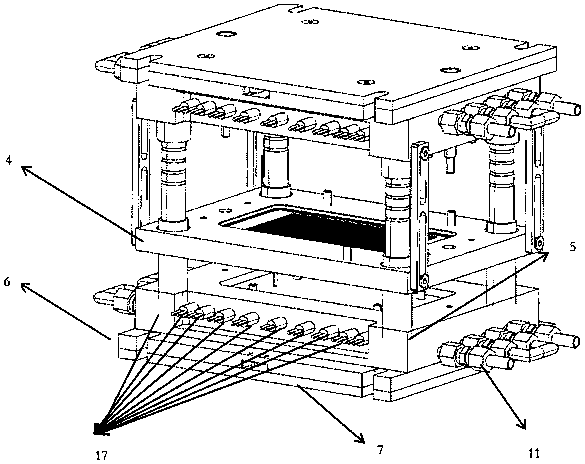

[0050] In the working state, first separate the upper mold 19 from the demoulding middle cavity 4 with a demoulding angle, fill the proportioned graphite and resin mixture into the demoulding middle cavity 4 and ensure that the material is sufficient and uniform. The upper end plate of the hydraulic press is fixed (that is, in the working state, the plate 3 on the heating and cooling plate, the plate 2 on the thermal resistance plate, and the upper cover plate 1 are all fixed), and the lower end plate of the hydraulic press is lifted upward at a uniform speed, driving the lower plate of the heating and cooling plate 5. The lower plate 6 and the lower cover plate 7 of the thermal resistance plate are raised upwards, so that the cavity of the mold demoulding is closed and the mixture of graphite and resin is extruded to complete the mold clamping process.

[0051] After the mold is closed, the temperature is rapidly raised to 300-340° C. by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com