Fiber laminate and manufacturing method of fiber laminate

A fiber laminate and manufacturing method technology, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of bloated movement, difficult to handle, occupying space, etc., and achieve good air permeability, easy storage, compact folding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The specific embodiment of the fiber laminated body for carrying out this invention, and the manufacturing method of this fiber laminated body is demonstrated based on drawing of an Example.

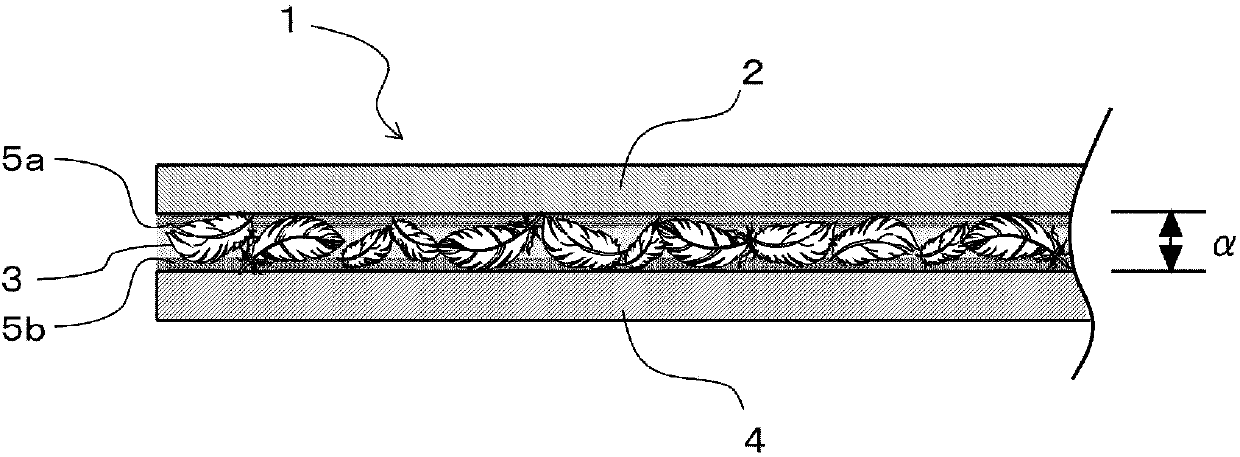

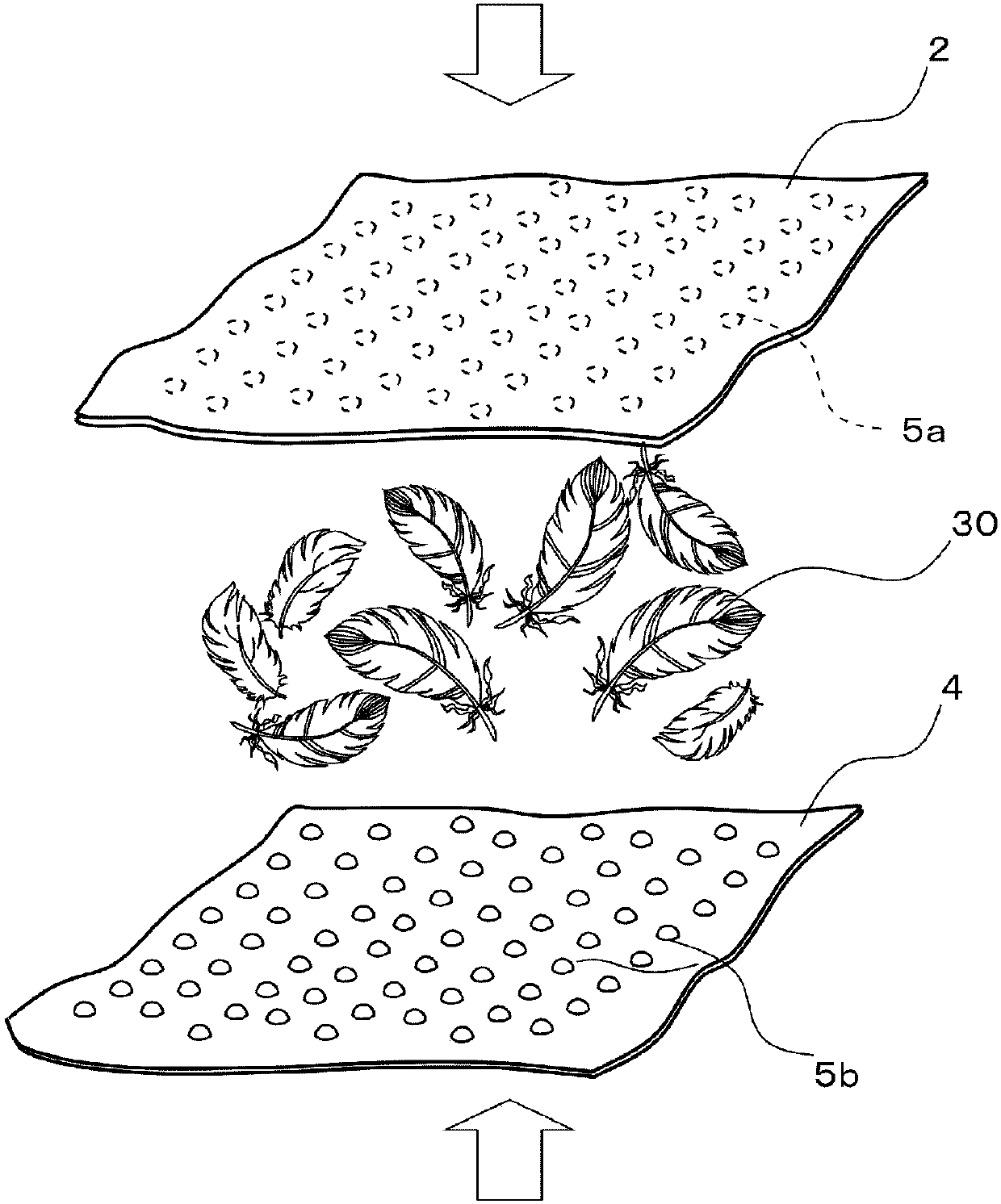

[0056] figure 1 is a cross-sectional view for explaining the fiber laminate of the present invention, figure 2 It is a perspective view for explaining the fiber laminated body of this invention.

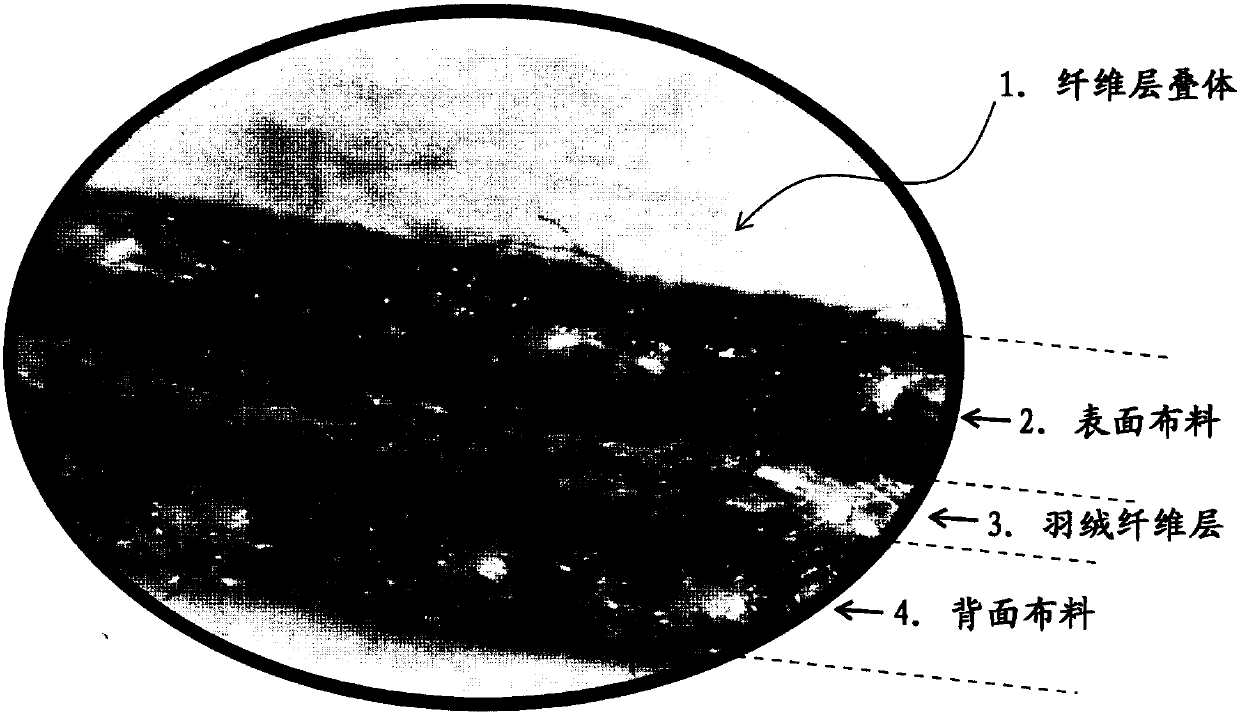

[0057] In the drawings, 1 is a fiber laminate, 2 is a surface fabric, 3 is a down fiber layer, 4 is a back fabric, and 5, 5a, 5b are adhesives.

[0058] exist figure 1 with figure 2 In the form of the embodiment of the fiber laminated body shown, the fiber laminated body 1 is constituted by sequentially laminating the surface fabric 2, the down fiber layer 3 and the back fabric 4, and the above-mentioned down fiber layer 3 is bonded to the fabric by adhesives 5a, 5b. The surface cloth 2 and the back cloth 4 are integrally formed.

[0059] In this embodiment, the surface cloth 2 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com