Method for preparing cannabidiol through high-speed countercurrent chromatography separation and purification

A high-speed countercurrent chromatography and cannabidiol technology, which is applied in the field of separation and purification of cannabidiol by high-speed countercurrent chromatography, can solve the problems of low CBD purity, complex composition, CBD loss and the like, and achieves optimized process parameters, simple preparation process, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Grind and dry 10kg industrial hemp, add it to 70% ethanol aqueous solution according to the ratio of material to liquid ratio of 1:5 (w / v, g / mL), mix thoroughly, and extract by ultrasonic for 120min, (control the temperature below 45°C, Protect from light), vacuum filter after the end of ultrasound, repeat the extraction of the obtained filter residue twice according to the above conditions, combine the filtrate, remove ethanol by vacuum rotary evaporation at 45 °C, concentrate to a relative density of 1.2, add 5-7 times of purified water, Under the condition of 5-8°C, sink in water for 24 hours, filter, and dry the precipitate under reduced pressure to obtain crude cannabis extract.

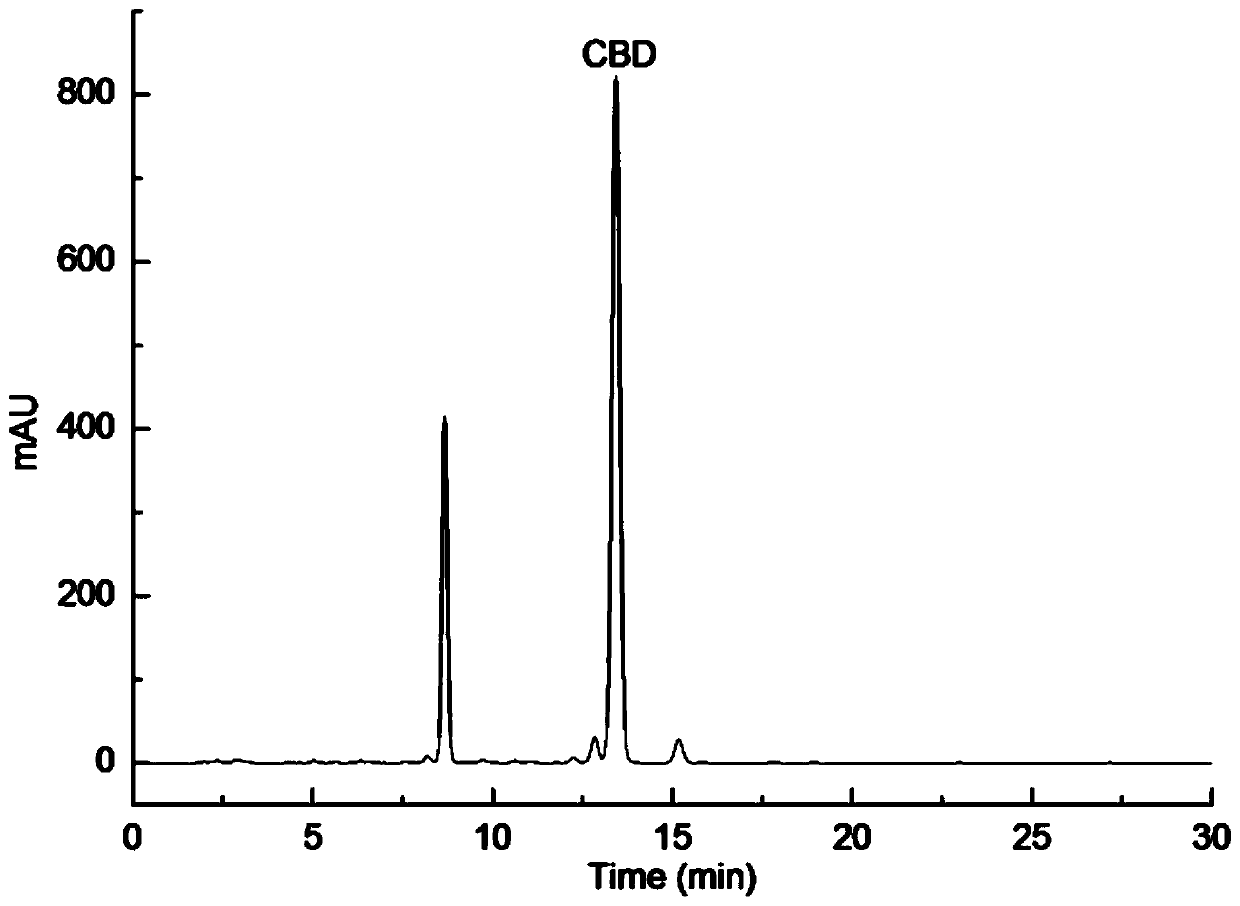

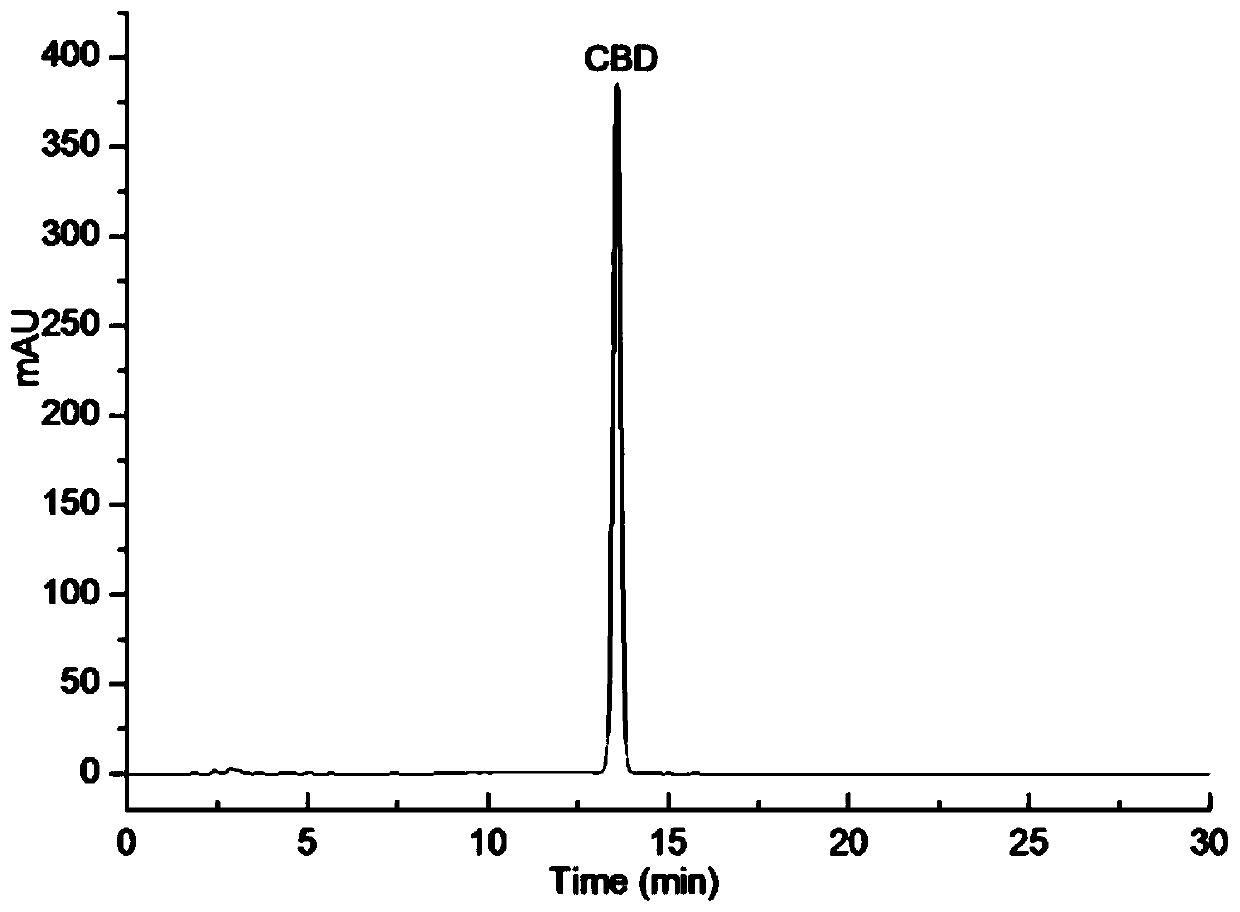

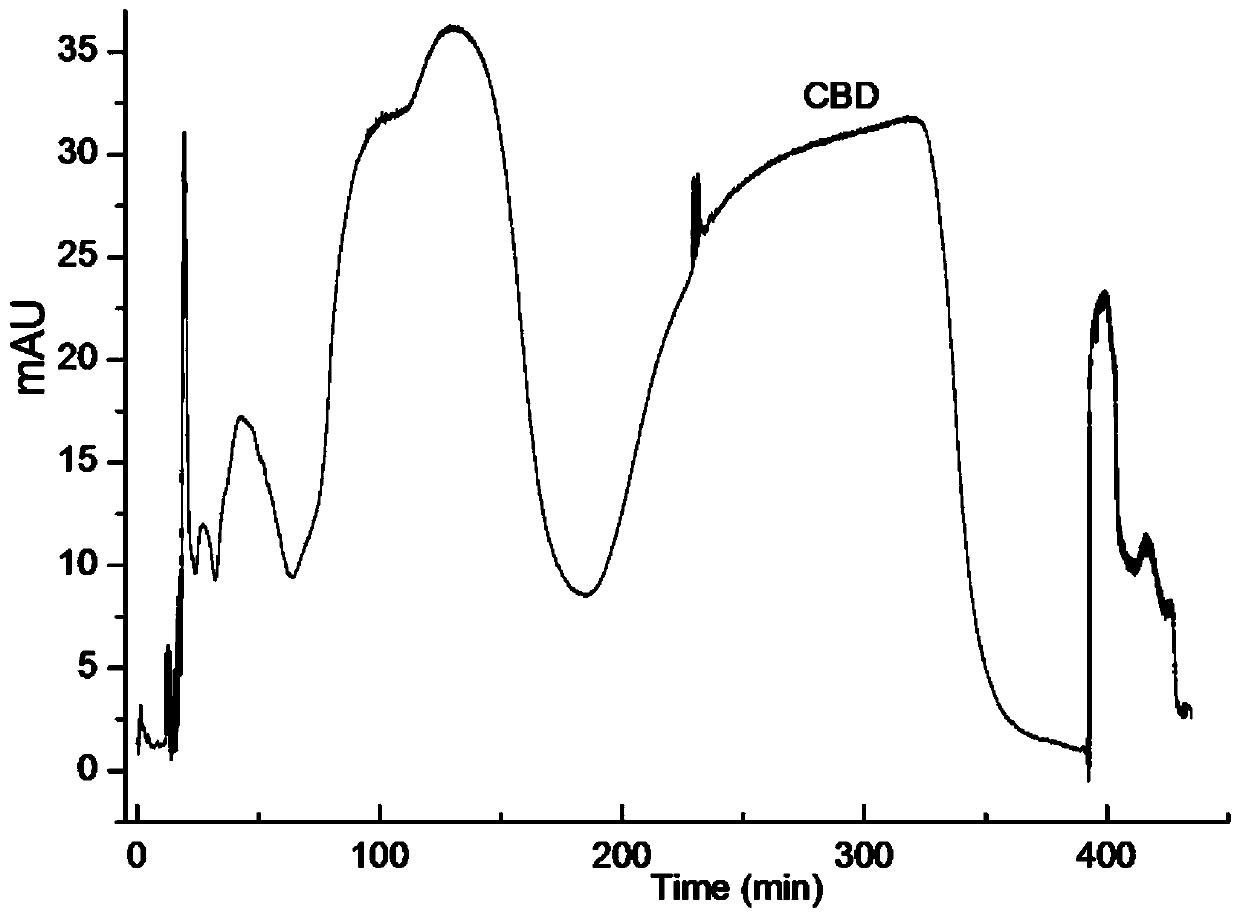

[0034] (2) Soak the AB-8 macroporous resin in ethanol for 24 hours, put it into a chromatographic column, and wash it with ethanol until the eluate plus an equal volume of deionized water becomes a transparent solution. Then wash with deionized water until the effluent is neutral; dis...

Embodiment 2

[0037] (1) Grind and dry 10kg of industrial hemp, add it to 80% ethanol aqueous solution according to the ratio of material to liquid ratio of 1:10 (w / v, g / mL), mix thoroughly, and extract by ultrasonic for 100min, (control the temperature below 45°C, Protect from light), vacuum filter after the end of ultrasound, repeat the extraction of the obtained filter residue twice according to the above conditions, combine the filtrate, remove ethanol by vacuum rotary evaporation at 45 °C, concentrate to a relative density of 1.2, add 5-7 times of purified water, Under the condition of 5-8°C, sink in water for 24 hours, filter, and dry the precipitate under reduced pressure to obtain crude cannabis extract.

[0038](2) Soak the D101 macroporous resin in ethanol for 24 hours, put it into a chromatographic column, and wash it with ethanol until the eluate plus an equal volume of deionized water becomes a transparent solution. Then wash with deionized water until the effluent is neutral; ...

Embodiment 3

[0041] (1) Grind and dry 10kg of industrial hemp, add it to 80% ethanol aqueous solution according to the ratio of material to liquid ratio of 1:8 (w / v, g / mL), mix thoroughly, and extract by ultrasonic for 120min, (control the temperature below 45°C, Protect from light), vacuum filter after the end of ultrasound, repeat the extraction of the obtained filter residue twice according to the above conditions, combine the filtrate, remove ethanol by vacuum rotary evaporation at 45 °C, concentrate to a relative density of 1.2, add 5-7 times of purified water, Under the condition of 5-8°C, sink in water for 24 hours, filter, and dry the precipitate under reduced pressure to obtain crude cannabis extract.

[0042] (2) Soak the AB-8 macroporous resin in ethanol for 24 hours, put it into a chromatographic column, and wash it with ethanol until the eluate plus an equal volume of deionized water becomes a transparent solution. Then wash with deionized water until the effluent is neutral; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com