Vortex type water garbage sucking device

A water garbage and absorption device technology, applied in water conservancy projects, cleaning of open water surfaces, construction, etc., can solve problems affecting water quality and appreciation, accumulation of garbage on water surfaces, and inability to last for a long time, so as to achieve immediate saving of manpower and cost Low, good immediate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

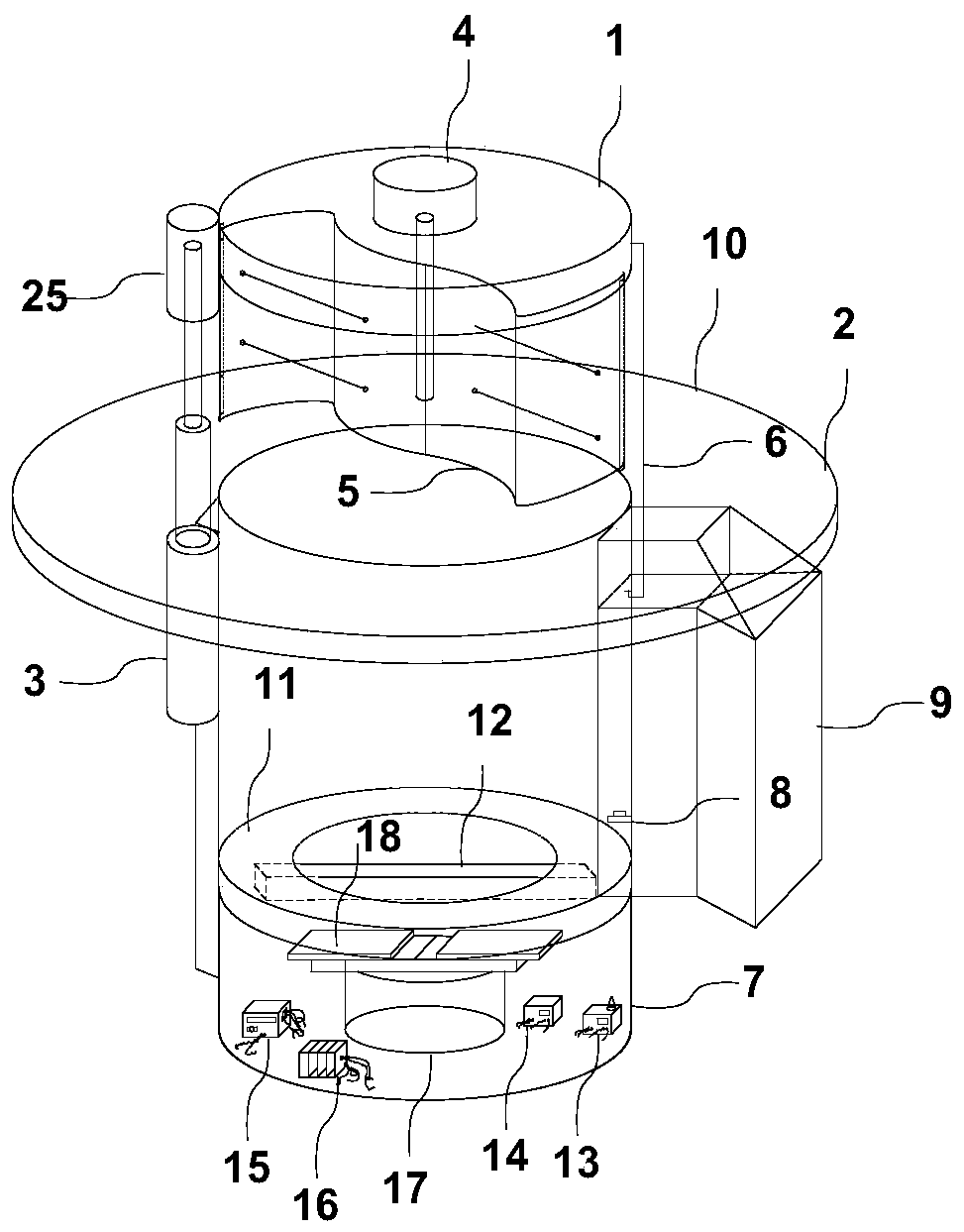

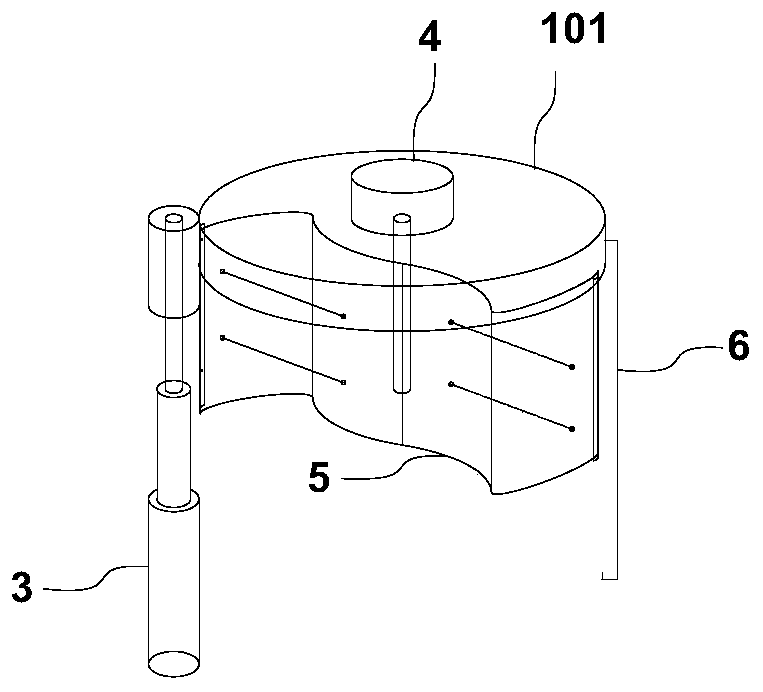

[0029] like figure 1 , figure 2 and image 3 As shown, the vortex type water garbage absorption device includes a bucket cover assembly 1, a bucket body assembly 2 and a control unit; a telescopic mechanism 3 is fixed between the bucket cover assembly 1 and the bucket body assembly 2;

[0030] The lid assembly 1 includes a lid 101, a lid motor 4, a scraper 5 and a limit switch 6; the lid motor 4 is placed in the center area of the top of the lid 101; the scraper 5 is placed longitudinally in the lid 101; the power output end of the lid motor 4 is fixedly connected to the power input end of the scraper 5; the limit switch 6 is vertically arranged on the lid assembly 1;

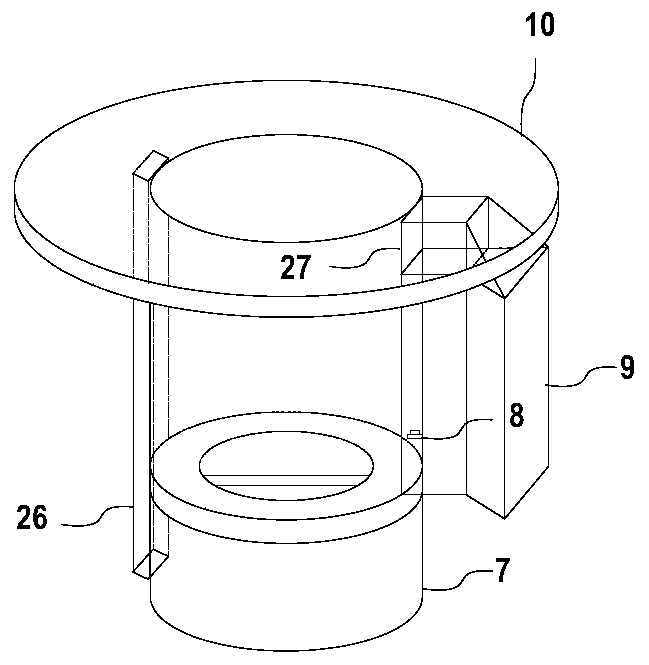

[0031] The bucket body assembly 2 includes a bucket body 7, a limit contact 8, a garbage temporary storage device 9, a buoyancy plate 10, a rotor support frame 11, a rotor 12, a rotor drive assembly and a control unit; the buoyancy plate 10 and the bucket body The upper ports of 7 are connected horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com