Heat pump drying system and control method

A heat pump drying and control method technology, applied in the direction of drying gas arrangement, drying, drying machine, etc., can solve the problems of unable to ensure indoor moisture at the same time, latent heat recovery and drying material heating requirements, etc., to avoid heat waste, avoid Uneven oil return, the effect of improving the energy efficiency of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

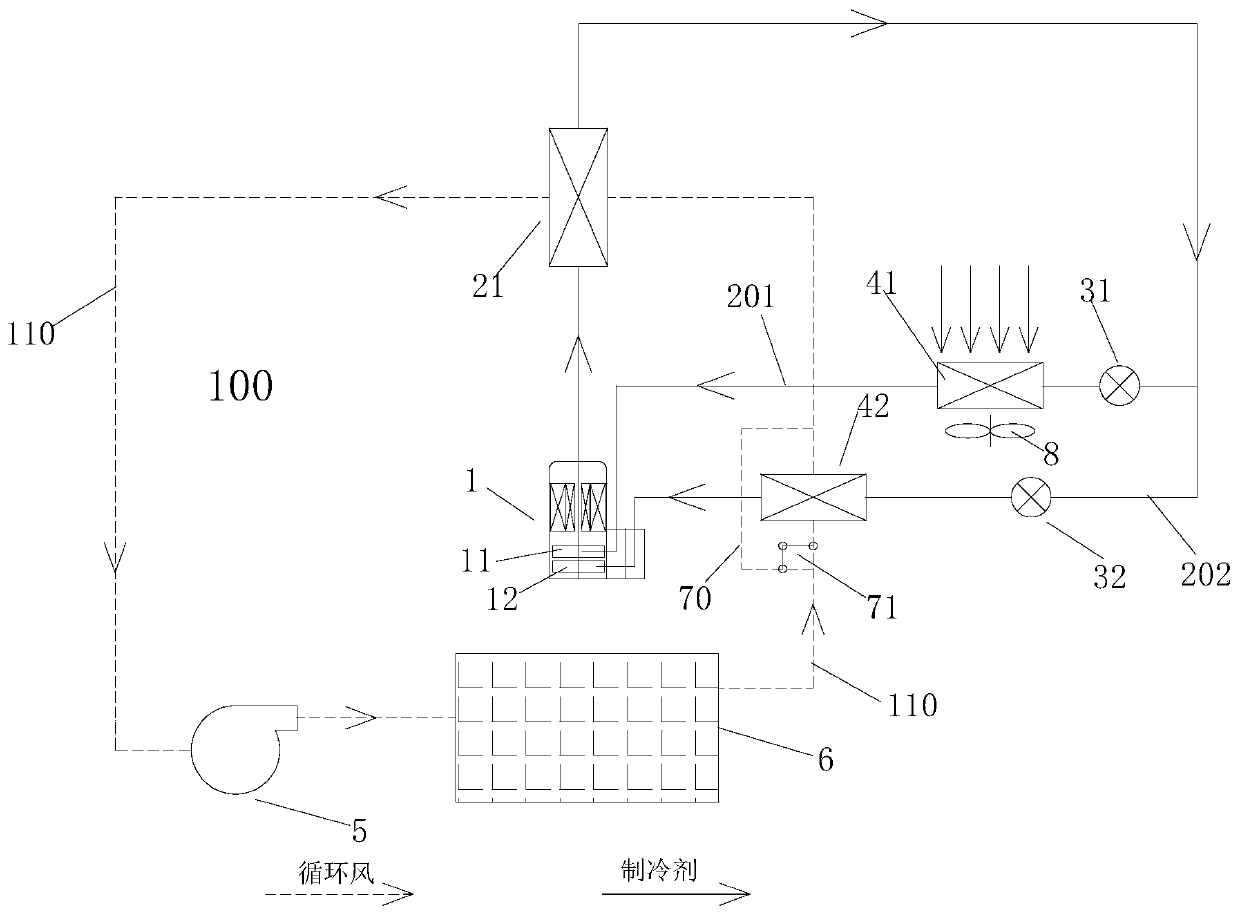

[0074] like figure 1 As shown, the present invention provides a heat pump drying system, which includes:

[0075] Compressor 1, drying device 100, drying condenser 21, outdoor evaporator 41 and indoor evaporator 42, the drying condenser 21 is connected with the exhaust end of the compressor 1, and can control the drying device 100 The outdoor evaporator 41 can be connected to the suction end of the compressor 1 to evaporate and absorb heat from the outside of the drying device 100, and the indoor evaporator 42 can also be connected to the The suction end of the compressor 1 is used to evaporate, absorb heat and dehumidify the air in the drying device 100 .

[0076] In the present invention, the evaporator is divided into an indoor evaporator and an outdoor evaporator, the indoor evaporator is arranged inside the air duct, and the outdoor evaporator is arranged in the environment outside the drying room, that is, one evaporator is respectively arranged inside and outside the d...

Embodiment 2

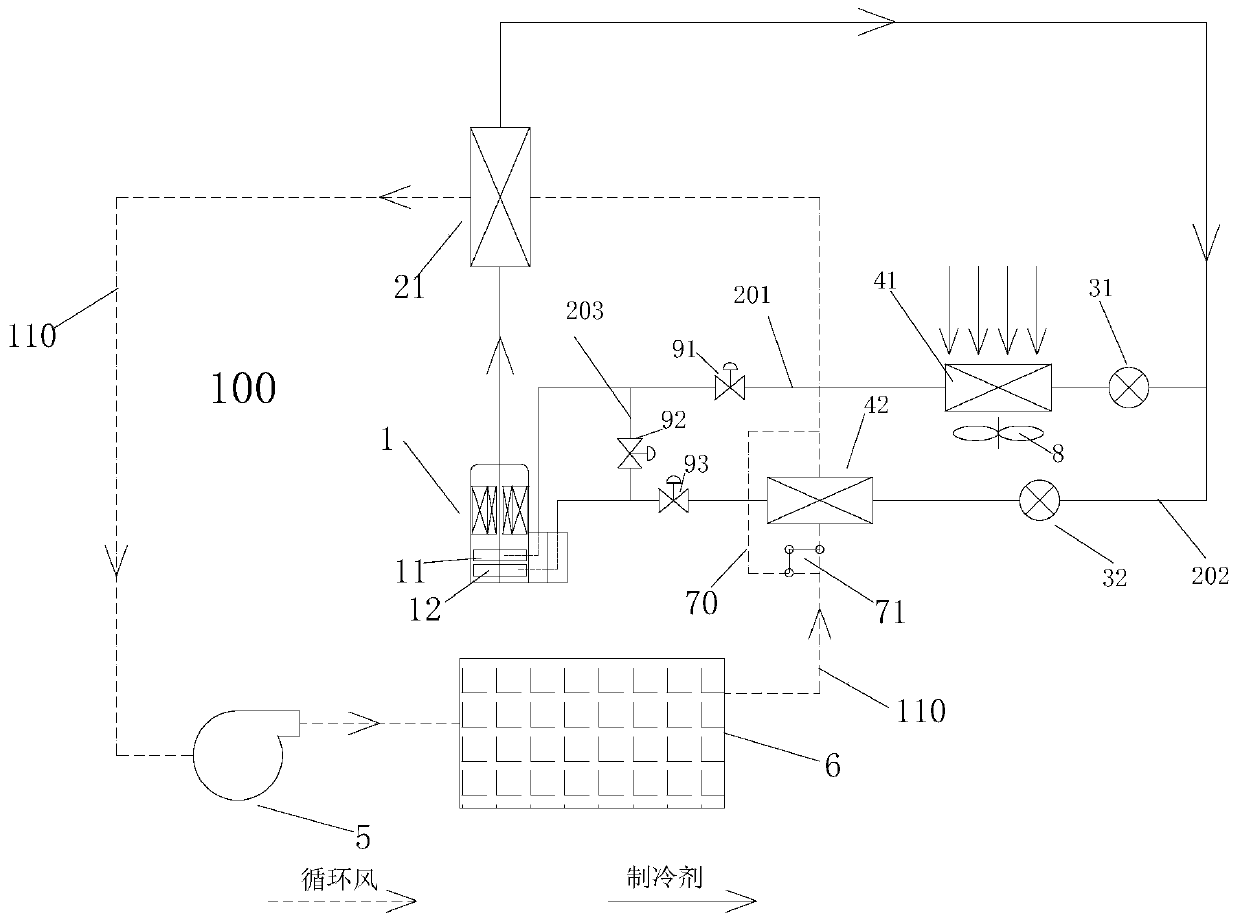

[0092] like figure 2 As shown, this embodiment is a further improvement made on the basis of Embodiment 1, and all the contents of Embodiment 1 are included in this embodiment, preferably,

[0093] A first two-way valve 91 is also provided on the first branch 201 and between the outdoor evaporator 41 and the suction end of the first compression cylinder 11 ;

[0094] A third two-way valve 93 is also provided on the second branch 202 and between the indoor evaporator 42 and the suction end of the second compression cylinder 12 ;

[0095] And the position between the first two-way valve 91 and the suction end of the first compression cylinder 11 and the position between the third two-way valve 93 and the suction end of the second compression cylinder 12 A third branch 203 is connected to the position, and a second two-way valve 92 is also arranged on the third branch 203 .

[0096] The two branches can be controlled separately through the first two-way valve set on the first ...

Embodiment 3

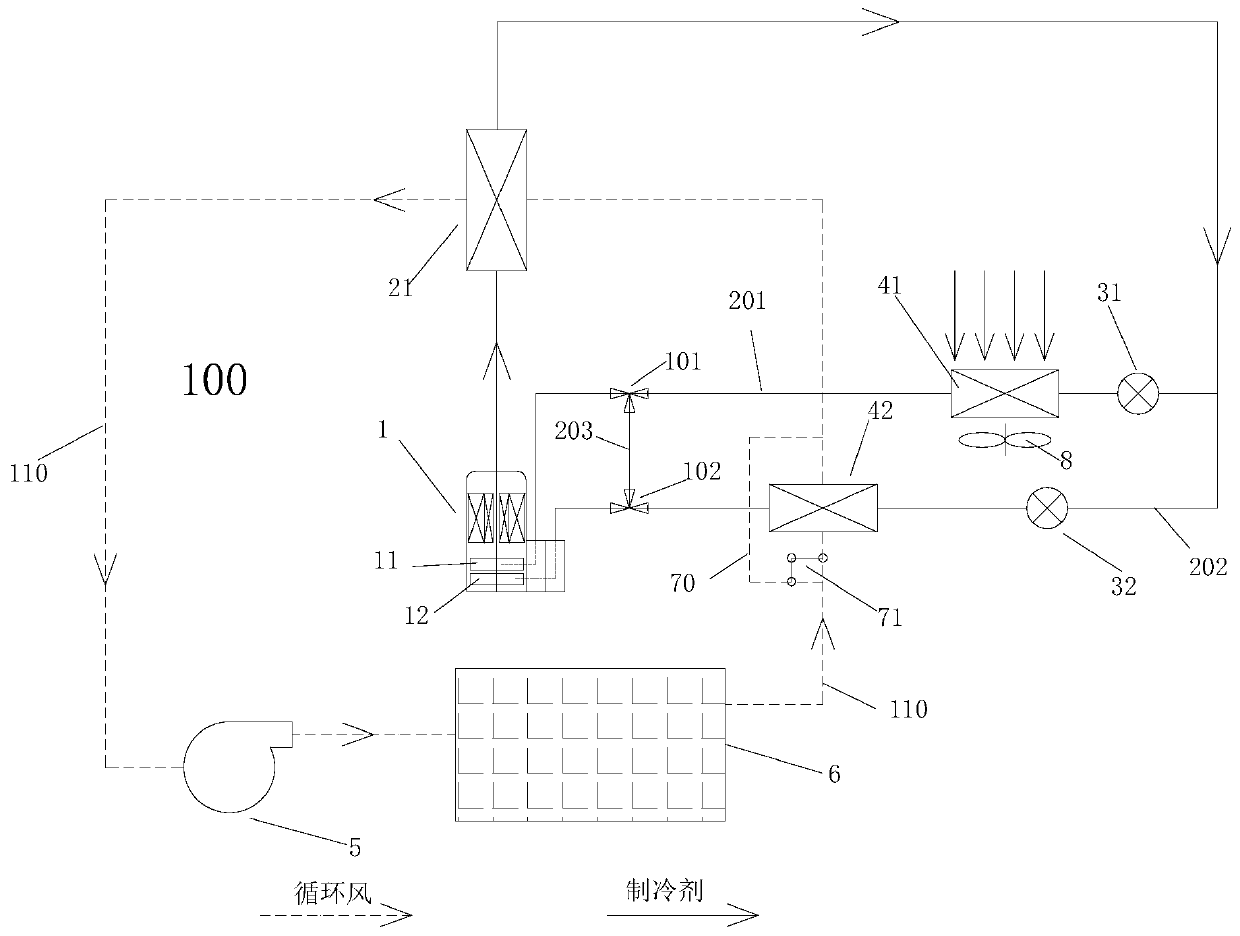

[0104] like Figure 4 As shown, this embodiment is a further improvement made on the basis of Embodiment 1, and all the contents of Embodiment 1 are included in this embodiment, preferably,

[0105] The heat pump drying system also includes an outdoor condenser 22, one end of the outdoor condenser 22 can communicate with the indoor evaporator 42, and the other end can communicate with the second compression cylinder 12; at this time, the drying condenser One end of 21 communicates with the outdoor evaporator 41 , and the other end communicates with the first compression cylinder 11 . By setting an outdoor condenser, part of the high-pressure and high-temperature refrigerant compressed by the compressor can flow through the outdoor condenser to release heat, so that part of the refrigerant flows through the drying condenser to heat the drying device or there is no refrigerant Enter the drying condenser to heat the drying device, so that the effect of constant temperature dehum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com