Method of off-line repair and pressure test of 650 relief valve of blast furnace

A release valve, off-line technology, applied in the direction of mechanical valve testing, etc., can solve the problems of increasing maintenance costs, spending a long time, increasing labor intensity of workers, etc., to reduce the possibility of loose valve cover sealing, reduce labor intensity, and reduce The effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

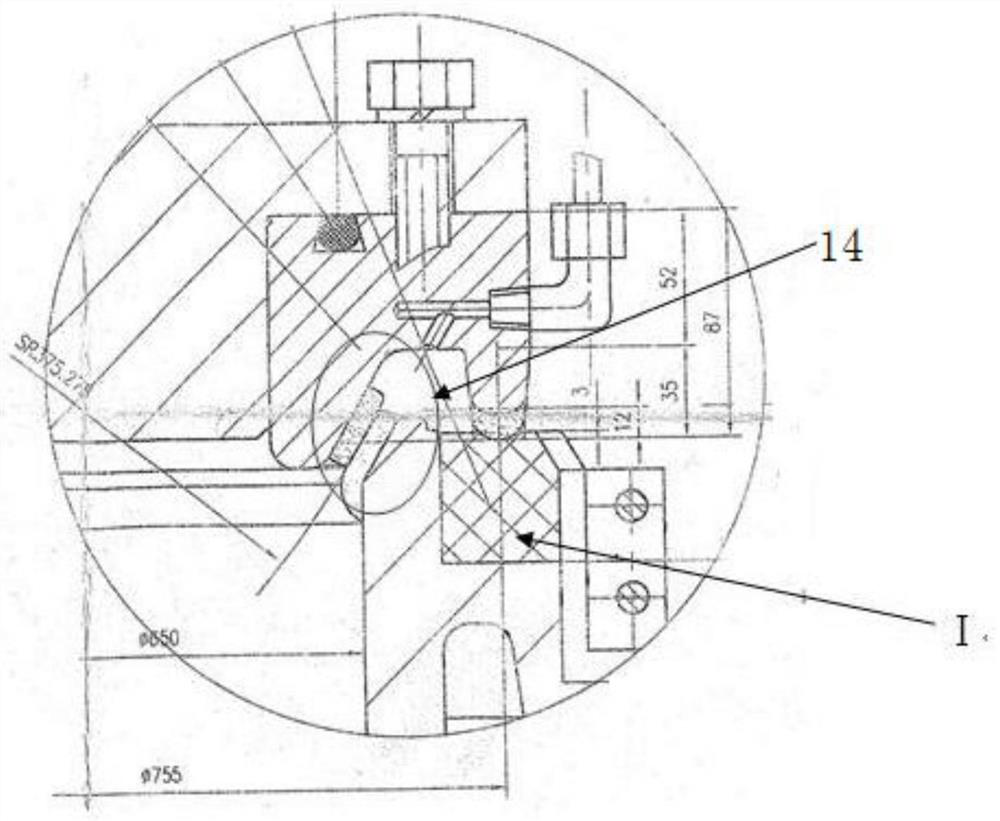

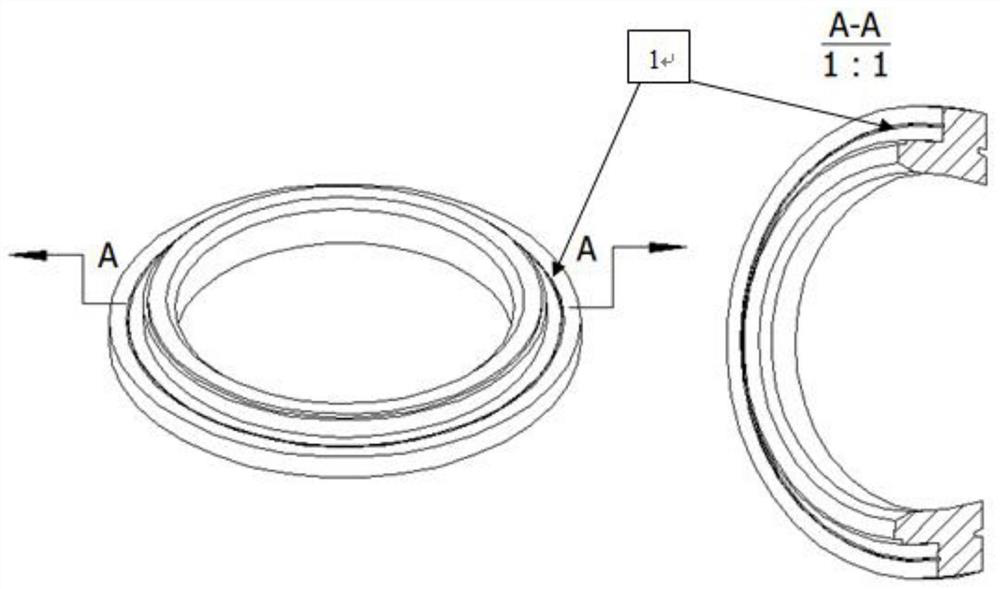

[0030] Embodiment 1: see figure 1 , figure 2 , figure 1 It is an enlarged drawing of the valve cover and seat assembly of the 650 relief valve, figure 2 It is the processing location map of the 650 relief valve seat. The seat of the 650 relief valve is processed. When all the repaired dimensions of the valve seat meet the requirements, a 1.5mm wide by 1.5mm is machined at the center of the seat on the part that is in contact with the seal. The deep groove, when the seal is stressed, will make a small part of the soft seal squeeze into the notch of 1.5mm*1.5mm, which is beneficial to the sealing of the 650 relief valve.

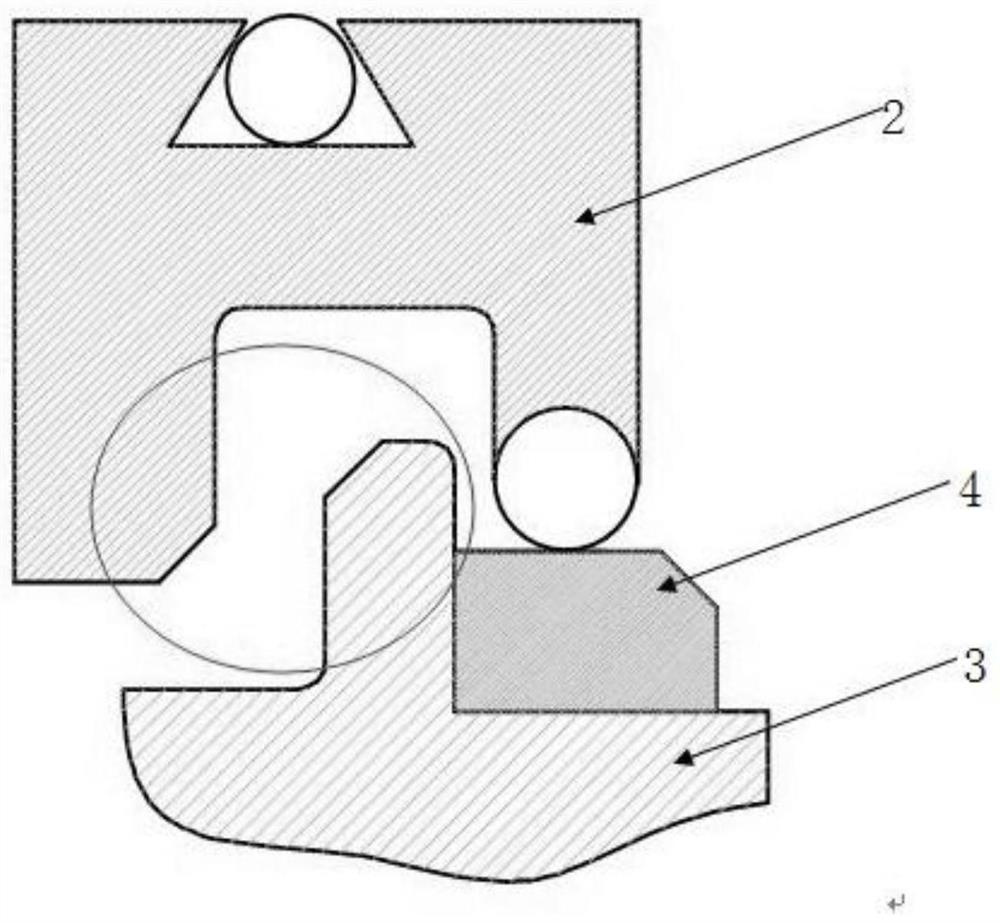

[0031] Please see image 3 , image 3 It is a schematic diagram of the modification of the valve cover and valve seat. Retrofit the hard sealing position of the original bonnet and valve seat (such as figure 1 with image 3 As shown), the hard seal between the bonnet and the valve seat is processed by vertical lathe, and the slope of the car is change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com