Hoop with self-lubricating capacity

A clamp and capacity technology, applied in the field of clamps with self-lubricating ability, can solve the problems of affecting the application effect of V-type clamps, uneven distribution of clamping force, increase in use cost, etc., and achieve an increase in axial clamping force. , the clamping force is uniform, and the effect of reducing the problem of loose sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

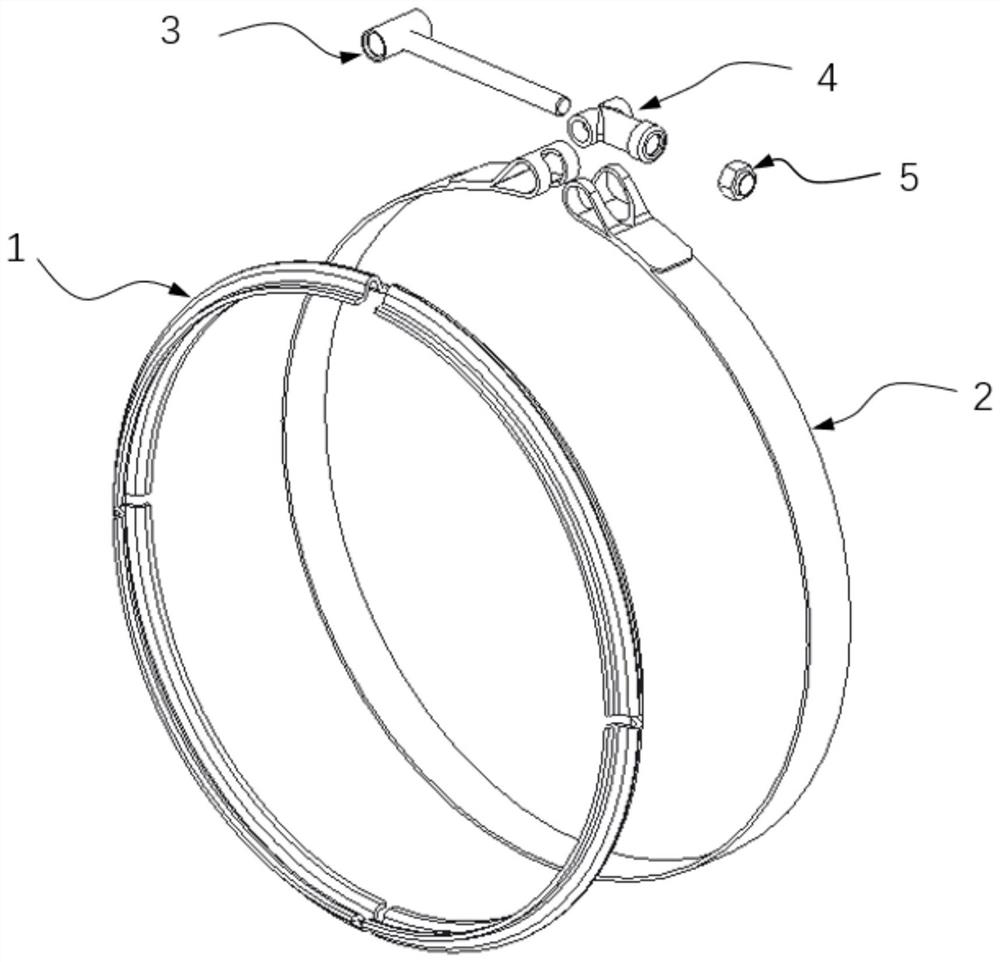

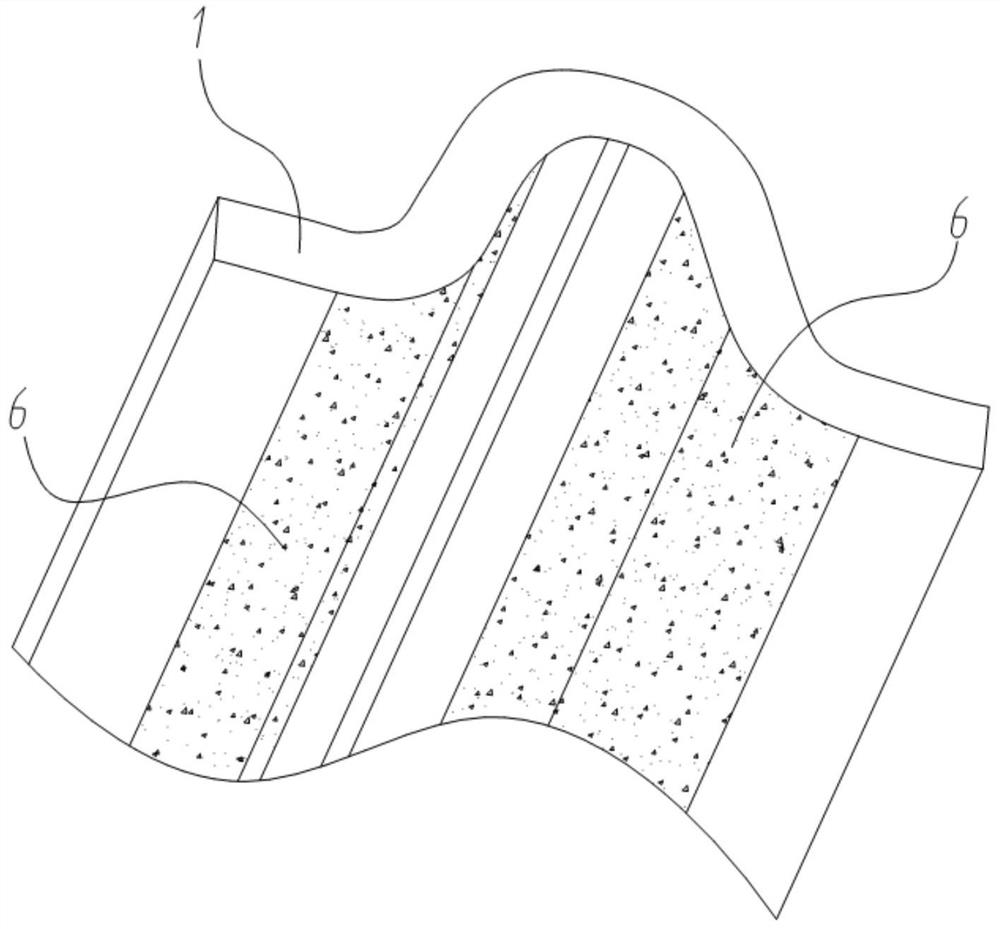

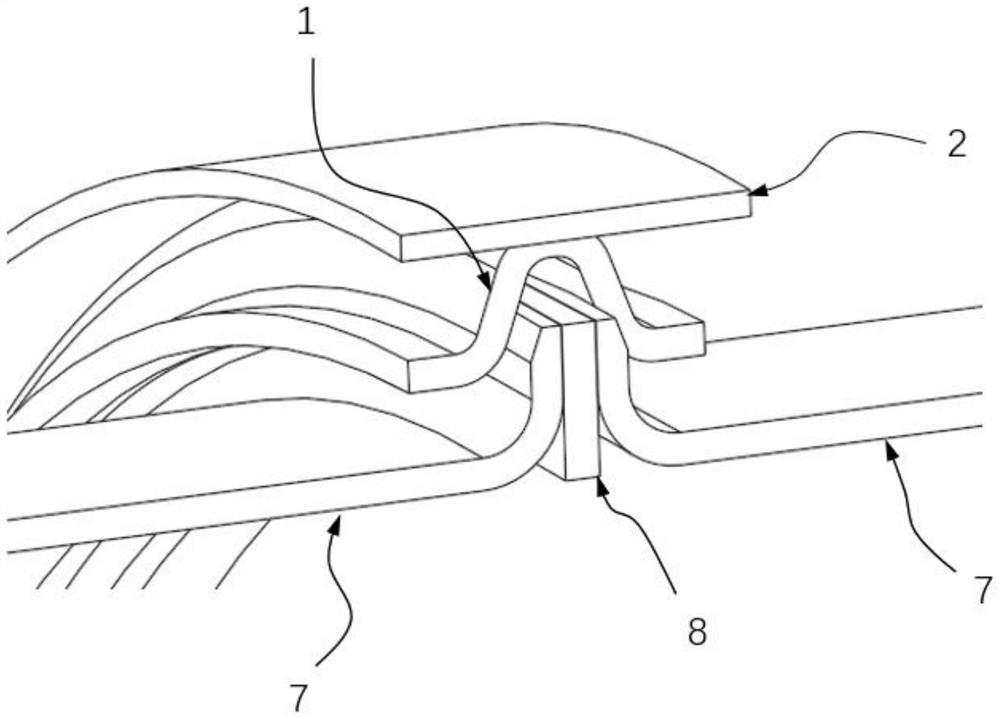

[0027] as attached figure 1 to attach Figure 8 Shown:

[0028] The invention provides a clamp with self-lubricating ability, which includes an outer clamping part 2; the outer clamping part 2 is an arc-shaped strip structure; The pressing parts 1 in the group are arranged in a circular array inside the outer clamping part 2, and the inner pressing part 1 and the outer clamping part 2 are connected by spot welding, and the inner pressing part 1 is a V-shaped structure; the V-shaped groove connection Welding spot 17, V-groove connection welding spot 17 is the spot welding connection point between inner compression part 1 and outer clamping part 2, and V-shaped groove connection welding spot 17 is evenly arranged in inner compression part 1 and outer clamping part 2; the strip ear 19, the strip ear 19 is arranged at the two ends of the outer clamping part 2, and the strip ear 19 is bent and formed and welded at the two ends of the outer clamping part 2; the ear welding point 1...

Embodiment 2

[0043] as attached Figure 8 Shown:

[0044] The present invention provides a clamp with self-lubricating ability. The difference between the second embodiment and the first embodiment is that the connection assembly further includes: a through-hole trunnion 20, which is a circular shaft structure. A group of through holes are provided in the middle of the side of the through hole trunnion 20, and the through hole trunnion 20 is rotatably connected to a group of strip roll ears 19 on the left side; the trunnion 21 with internal thread is Round shaft structure, a group of threaded holes are opened in the middle of the side of the trunnion 21 with internal thread; the trunnion 21 with internal thread is rotatably connected in a group of strip ear 19 on the right side; ordinary bolt 22, ordinary bolt 22 The through hole passing through the through-hole trunnion 20 is threadedly connected with the trunnion 21 with internal thread, and in use, two sets of strip rolling lugs are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com