Intelligent detection machine bench

An intelligent detection and machine technology, applied in the direction of optical testing defects/defects, can solve the problems of poor usability, poor universal type, cumbersome line change, etc., and achieve the effect of powerful function, strong versatility, and simple line change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

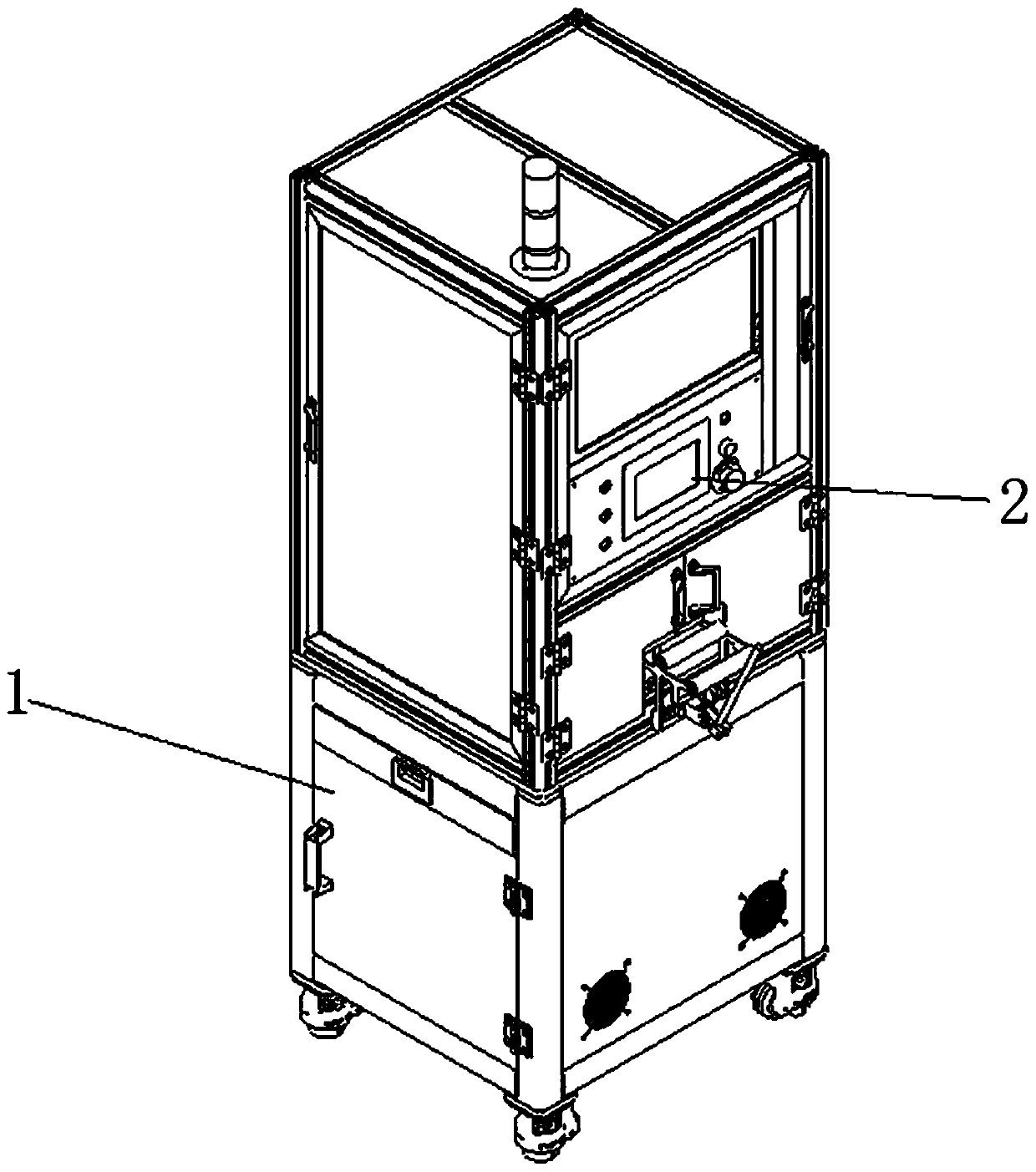

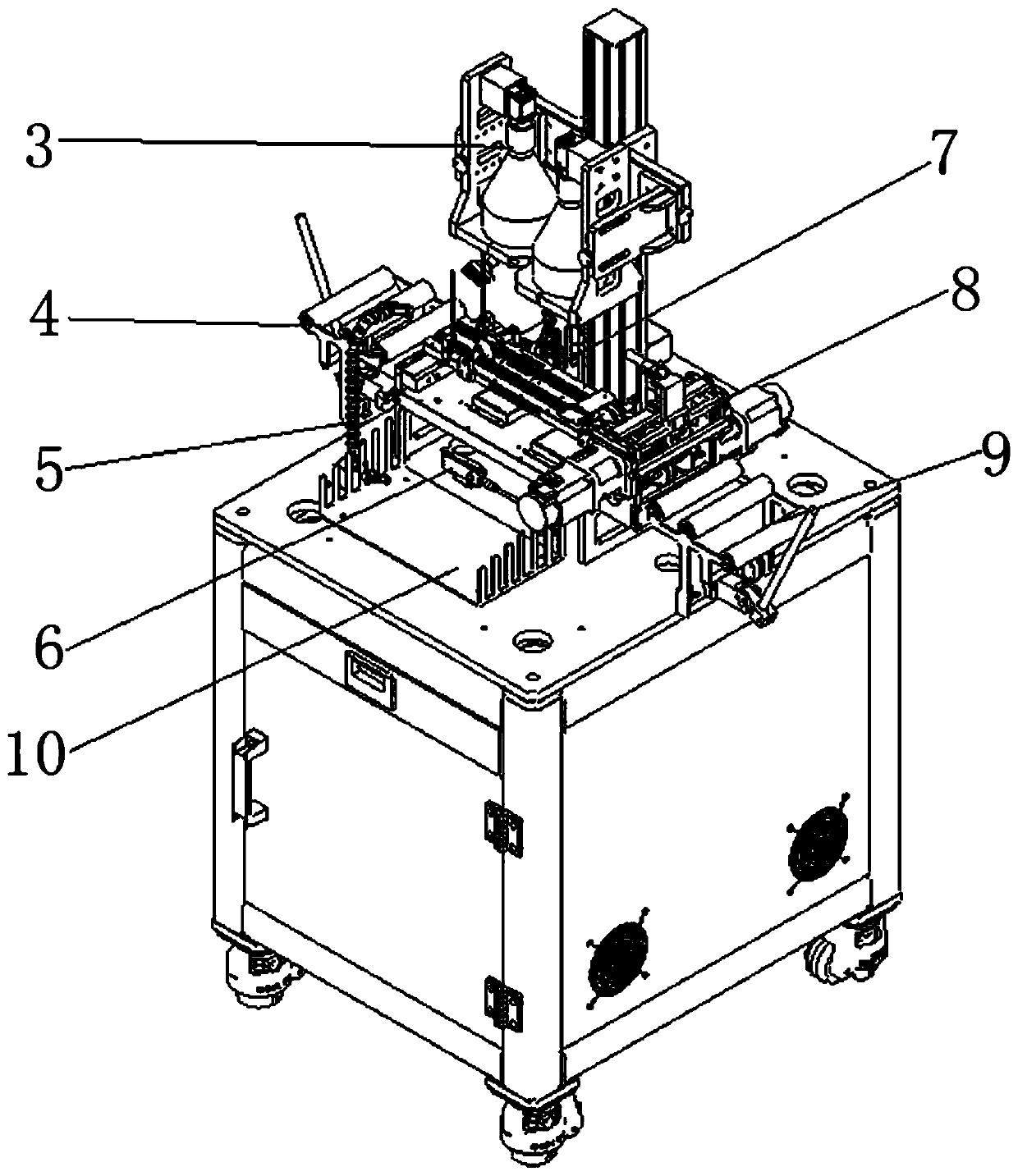

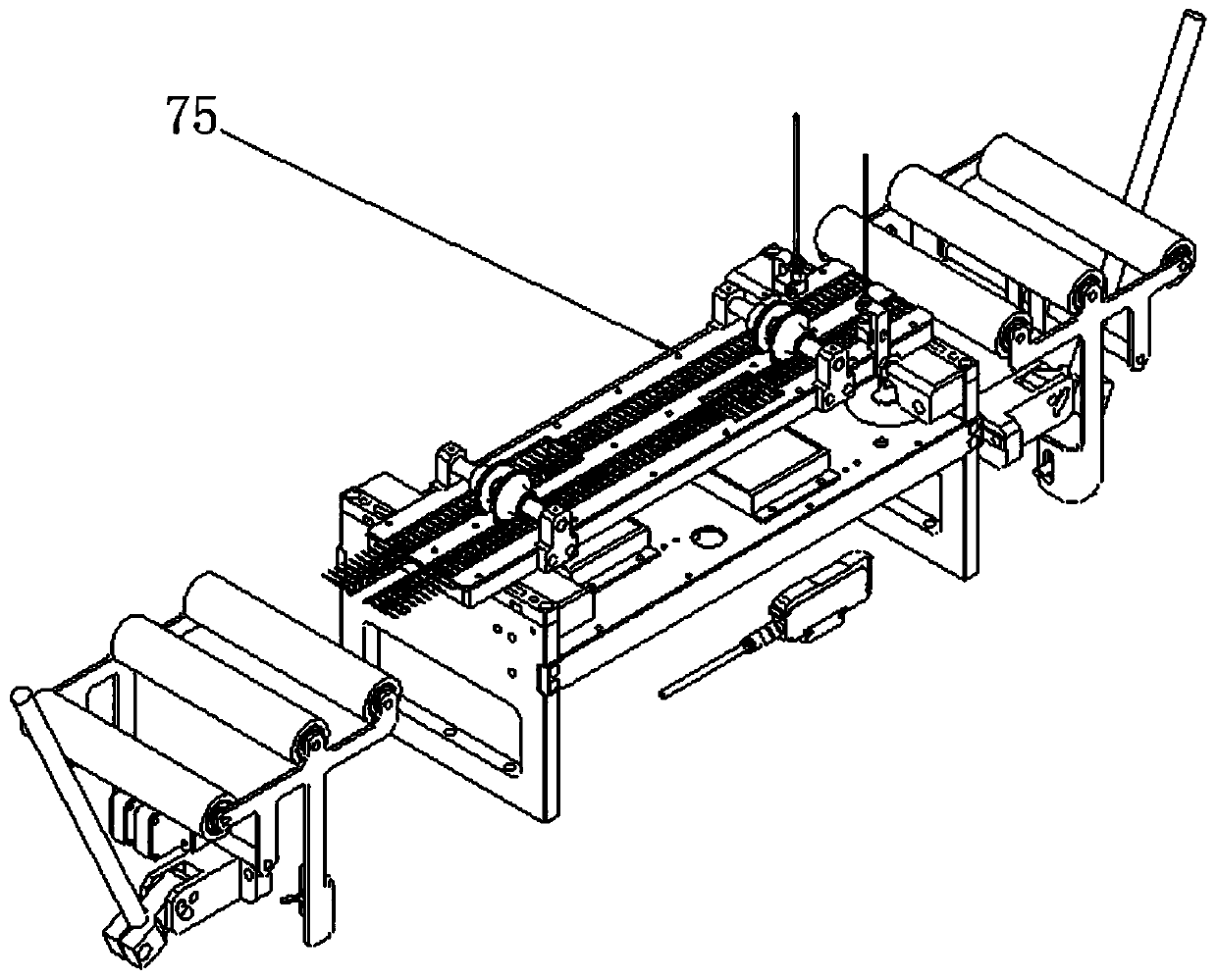

[0027] Embodiment: As shown in the accompanying drawings, this intelligent detection machine mainly includes a control cabinet 1 and a man-machine interface 2 installed above the control cabinet 1, a CCD system 3, a feeding end guide and induction mechanism 4, and an air blowing mechanism 5 , trigger optical fiber 6, quick-change flow channel module 7, material pulling mechanism 8, discharge end guide and induction mechanism 9, flow channel storage location 10, the continuous material tape produced by the punch press passes through the feed end guide and induction mechanism 4 Guided into the quick-change flow channel module 7, a blowing mechanism 5 is arranged beside the guide and induction mechanism 4 at the feed end, and the quick-change flow channel module 7 is connected to the pulling mechanism 8. The material belt moves forward in a straight line, and finally the trigger signal is given by the trigger optical fiber 6 below the quick-change runner module 7 to make the CCD s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com