Light diffusion layer and light diffusion sheet

A technology of light diffusing layer and light diffusing sheet, applied in the field of light diffusing, can solve the problems of inability to meet the requirements, the degree of reduction cannot reach direct detection, and the angle of incident light is highly dependent, so as to achieve the effects of suppressing noise, stabilizing color temperature, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

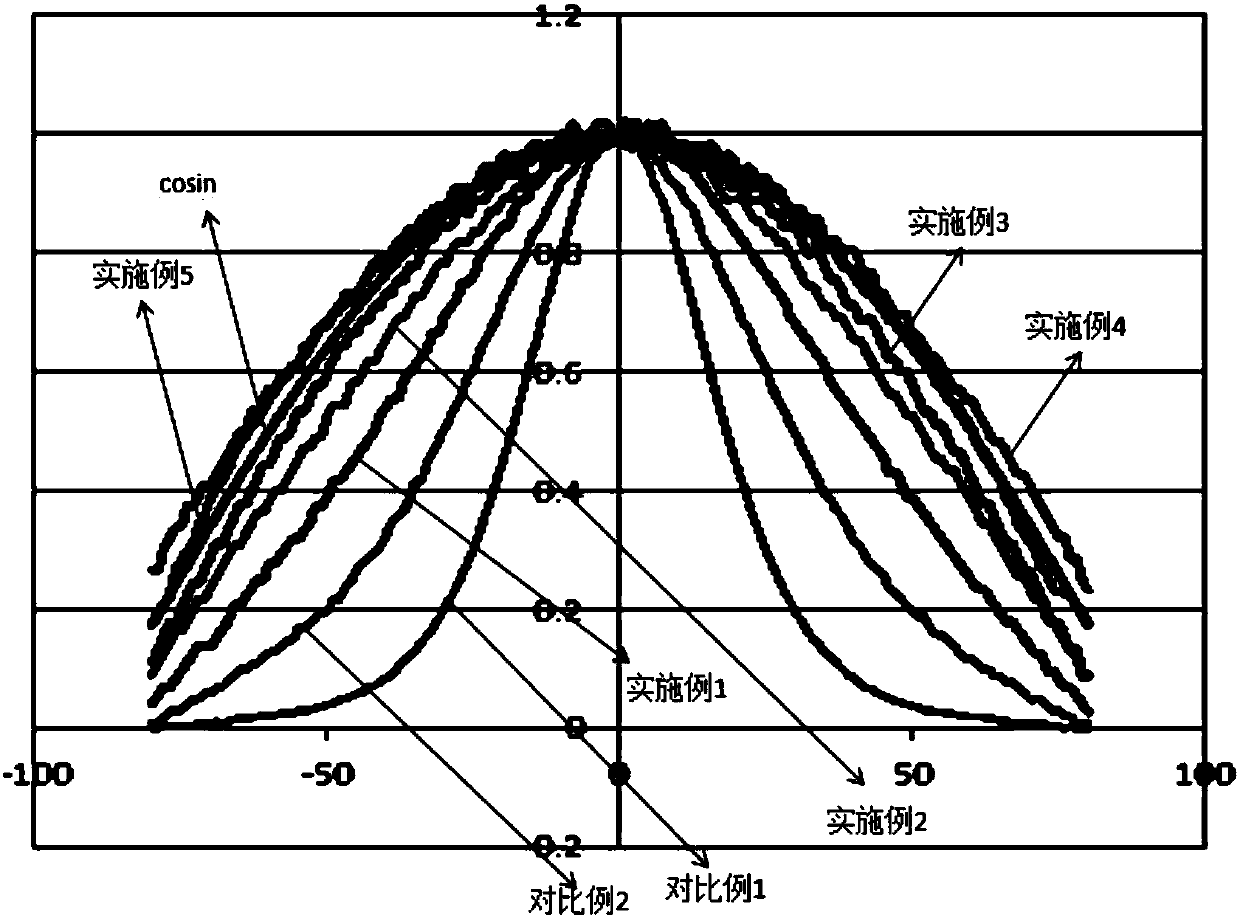

Embodiment 1

[0033] Formulation and preparation of coating liquid:

[0034]

[0035]

[0036] Mix and stir the above resin, additives, and solvent for 5 minutes, then add particles to disperse at high speed for 45 minutes, finally add curing agent and stir for 5 minutes, and apply the finished coating solution on both sides of the PET substrate with RDS 18# spatula superior.

Embodiment 2

[0038] Formulation and preparation of coating liquid:

[0039]

[0040] Mix and stir the above resin, additives, and solvent for 5 minutes, then add particles to disperse at high speed for 45 minutes, finally add curing agent and stir for 5 minutes, and apply the finished coating solution on both sides of the PET substrate with RDS 18# spatula superior.

Embodiment 3

[0042] Formulation and preparation of coating liquid:

[0043]

[0044]

[0045] Mix and stir the above resin, additives, and solvent for 5 minutes, then add particles and disperse at high speed for 45 minutes, finally add curing agent and stir for 5 minutes, and apply the finished coating solution on both sides of the PET substrate with RDS 50# spatula superior.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com