High-strength and corrosion-resistant black titanium clock ornament and production process thereof

A high-strength, anti-corrosion technology, applied in the field of watches, can solve the problems that the anti-corrosion ability of the electroplated black surface cannot meet the requirements of high standards and high-quality products of the enterprise, increase the cost of the enterprise, and the instability of the electroplating layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

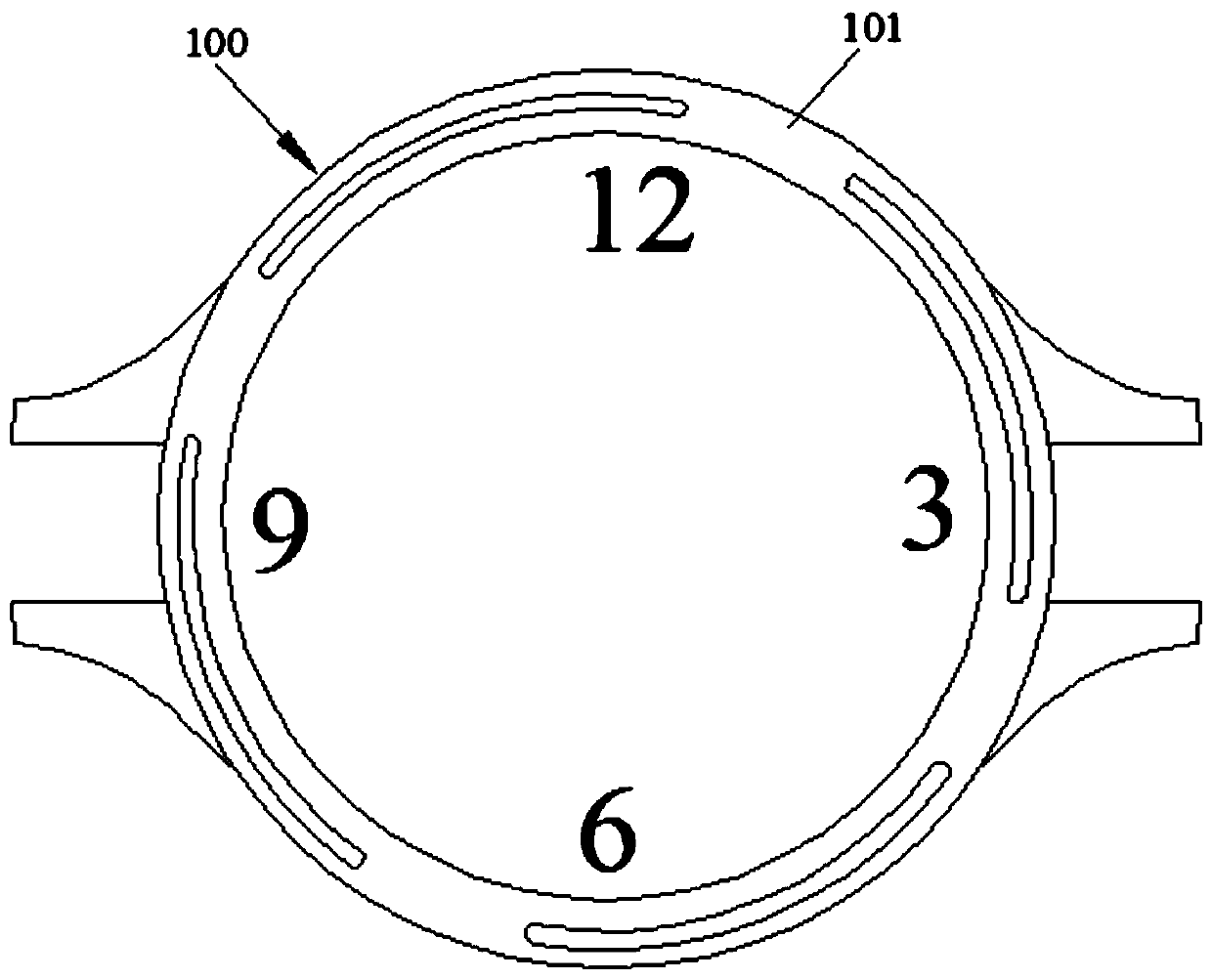

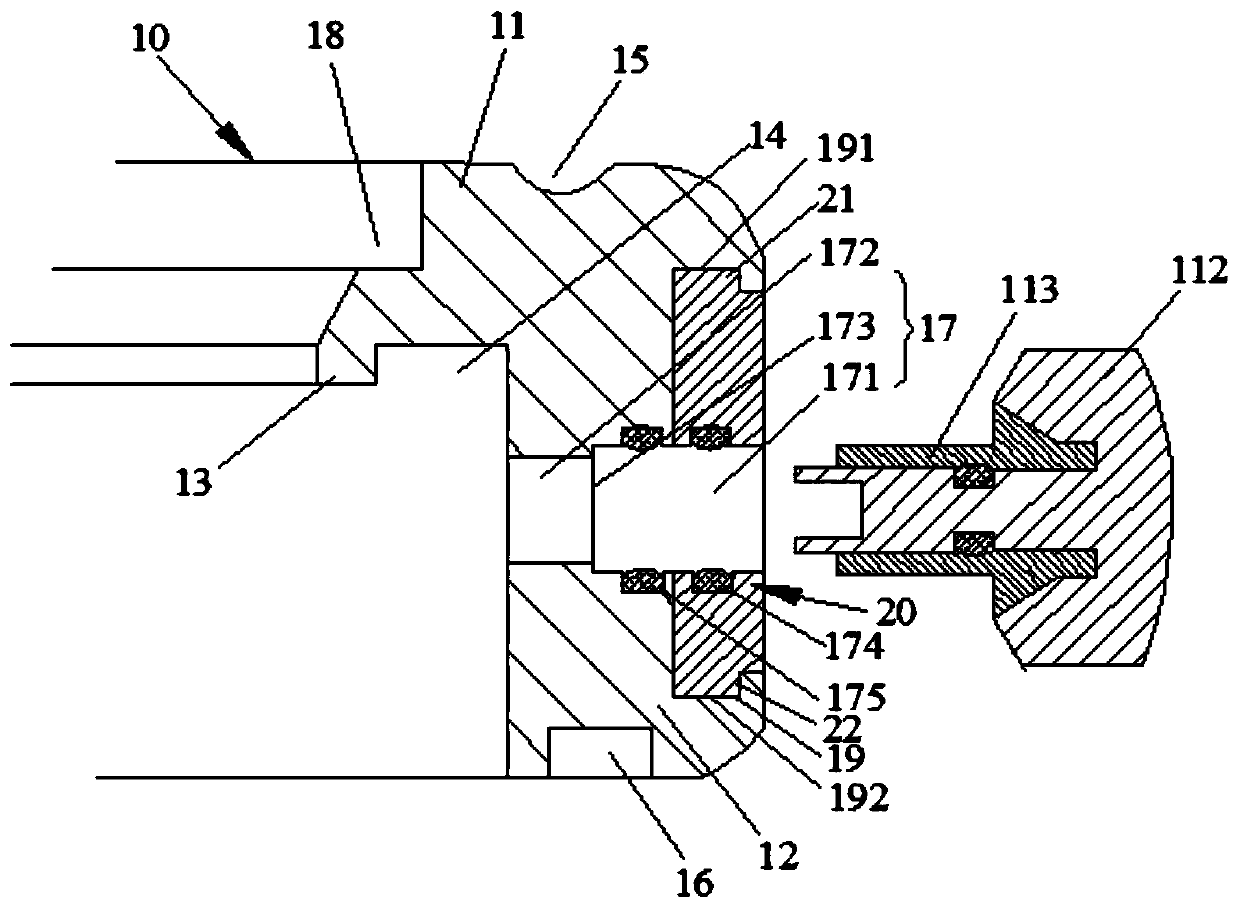

[0056] Please refer to Figure 1 to Figure 3 As shown, it shows the specific structure of the preferred embodiment of the present invention, which is a high-strength anti-corrosion black titanium watch ornament, which is applied to the watch. in, figure 1 is a watch 100, the black titanium watch trim of the present invention is applied to figure 1 Shown on the watch 100.

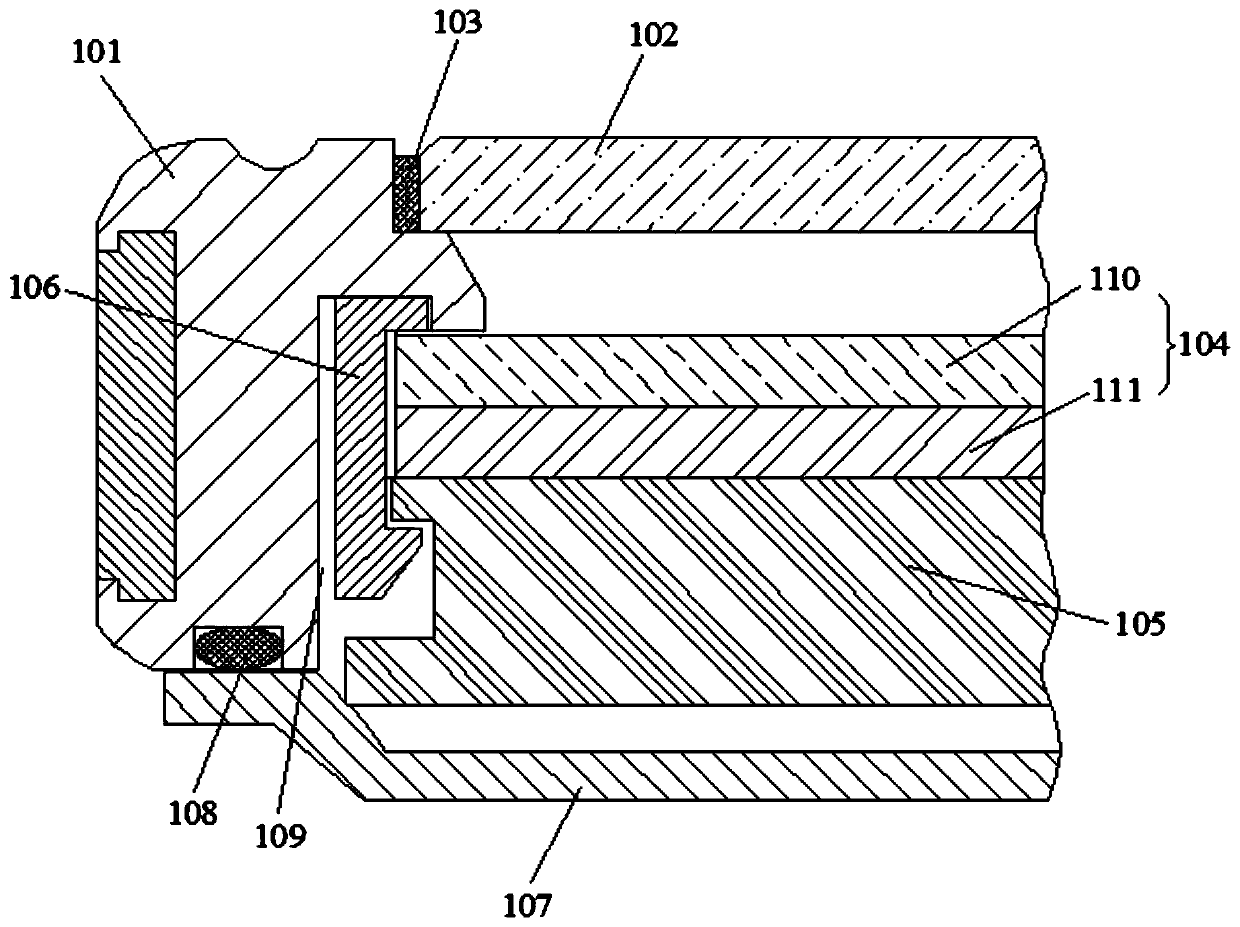

[0057] figure 2 is an enlarged cross-sectional view of a main part of the internal structure of a watch 100 . The watch 100 includes a watch case 101 . A glass cover 102 is mounted on the upper portion of the watch case 101 through a gasket 103 . A watch dial 104 and a watch module 105 are accommodated in the watch case 101 and thus attached to an inner frame 106 . A bottom cover 107 is attached to the lower surface of the watch case 101 via a waterproof gasket 108 .

[0058] The watch module 105 has at least an analog function out of both an analog function and a digital function. The watch module ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com