A Parametric Modeling Method of Flat Finite Element Mesh for High Energy Beam Machining Rhombus Pattern

A grid parameterization and modeling method technology, applied in design optimization/simulation, etc., can solve problems such as low precision, error-prone, cumbersome steps, etc., and achieve the effects of good end-face consistency, fast response speed, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below with reference to the accompanying drawings and examples.

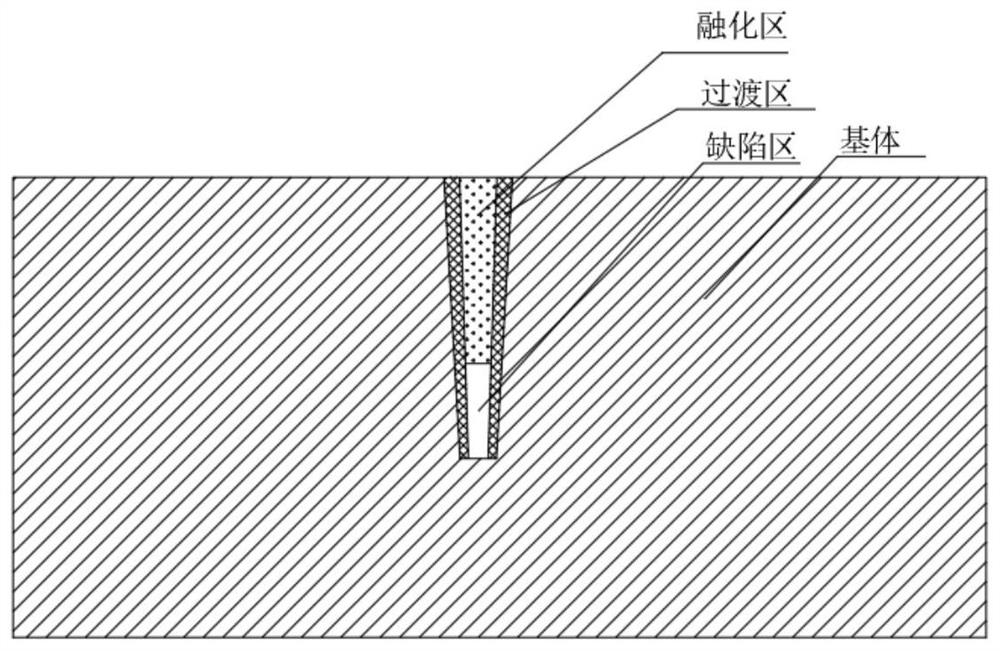

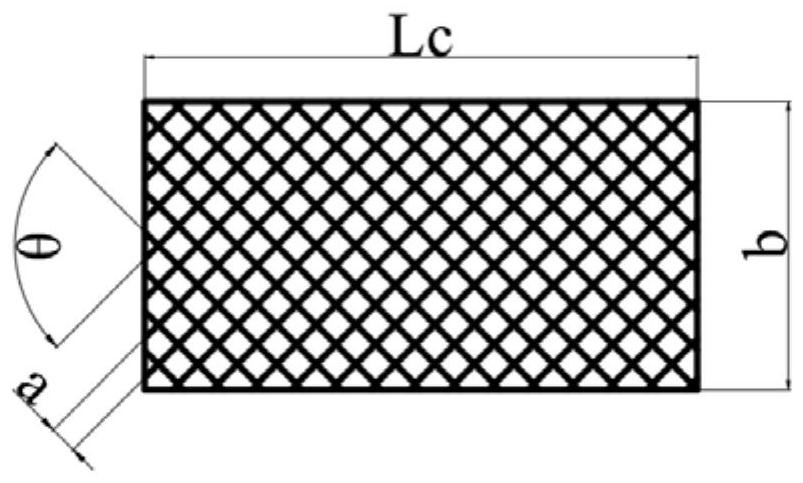

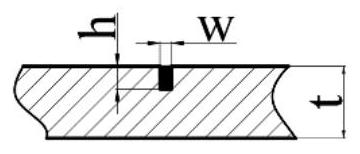

[0050] The present invention provides a flat finite element grid parametric modeling method for processing rhombic patterns with high-energy beams, using nodes to construct rhombic hexahedral grids to divide the flat grids containing high-energy beam groove lines, and filling the four sides of the flat grids. Then, according to the proportional relationship between the high-energy beam groove line and the width and height directions of the plate, the number of units in the high-energy beam groove line defect area is determined, and the regional mesh of the high-energy beam groove line defect area is deleted along the width and height directions of the plate to complete the construction. mold, such as Figure 10 , Figure 11 and Figure 12 As shown, it specifically includes the following steps:

[0051] Step 1. Summarize the geometric characteristics of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com