Plastic garbage crushing device

A technology of plastic waste and crushing device, applied in the direction of magnetic separation, solid separation, press, etc., can solve the problems of insufficient crushing degree, separation, large size of fragments and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

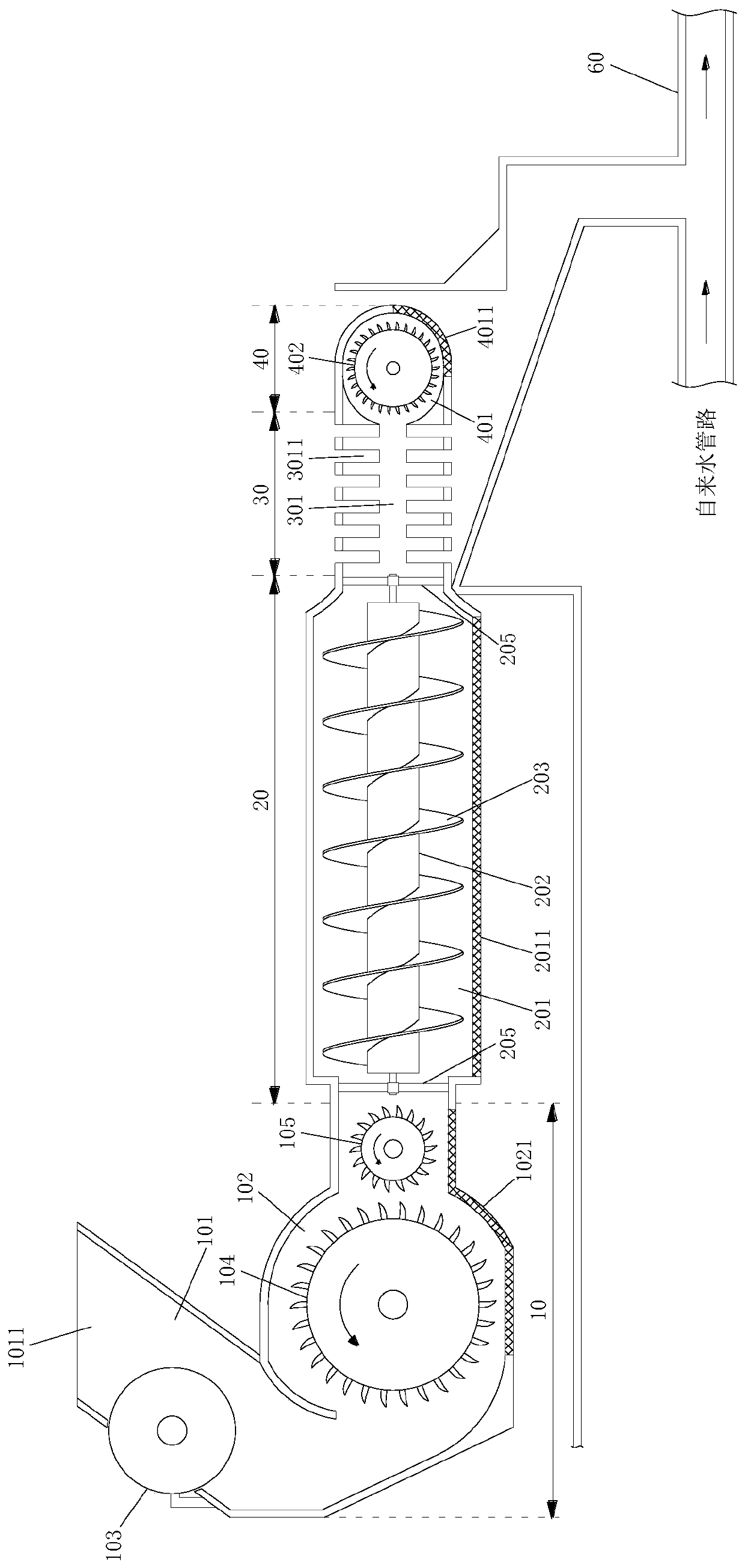

[0043] Such as Figure 1-Figure 7 As shown, the present embodiment provides a plastic waste crushing device, which includes a first segment 10 , a second segment 20 , a third segment 30 and a fourth segment 40 in which the shells are sequentially connected.

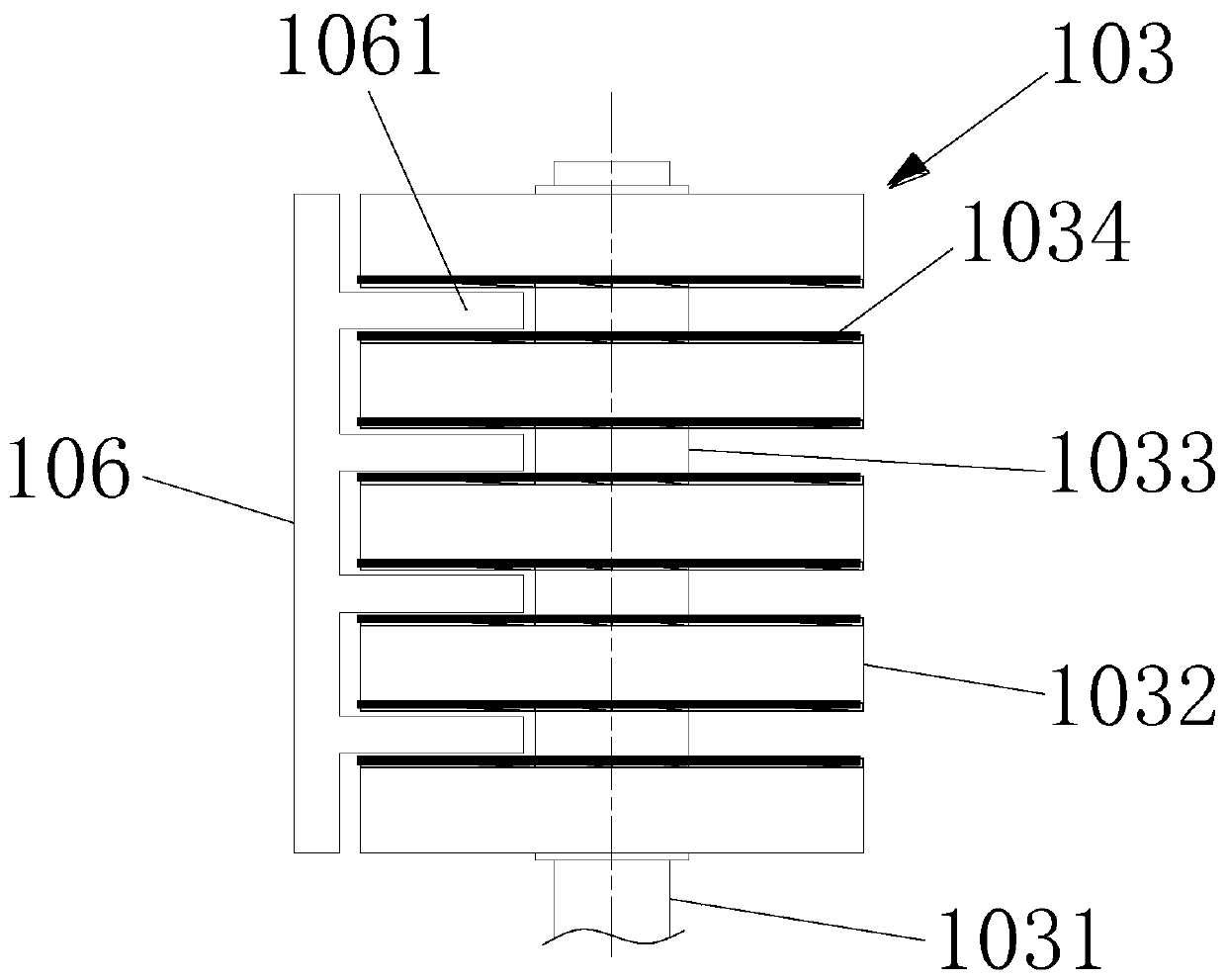

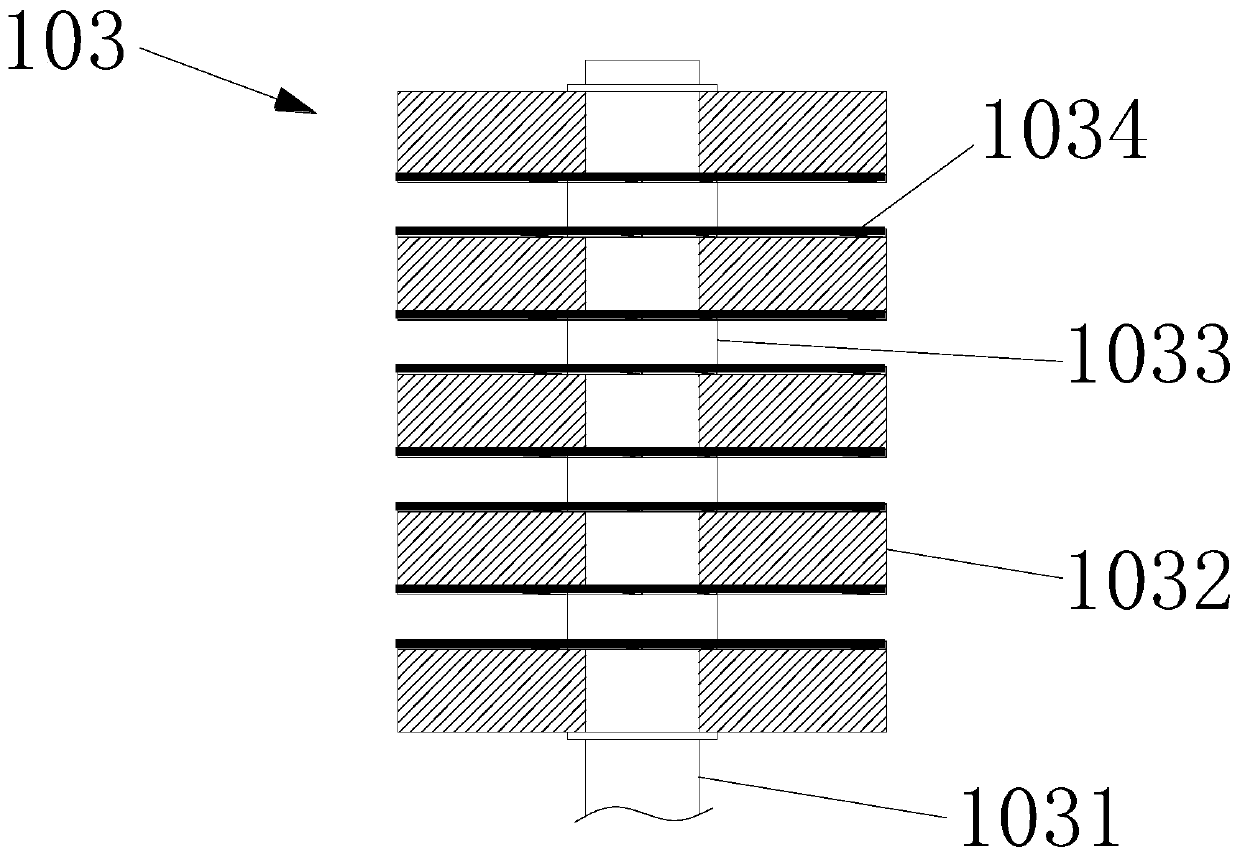

[0044] The first section 10 includes a feed channel 101 and a first cavity 102, the feed channel 101 is connected to the top of the first cavity 102 and is inclined, the top of the feed channel 101 has a feed port 1011, and A squeeze roller 103 for extruding plastic is installed in the material channel 101, and a magnet is arranged on the squeeze roller 103 to absorb ferromagnetic substances. The first cavity 102 is successively equipped with coarse crushing rollers according to the moving direction of the material. roller 104 and fine crushing roller 105.

[0045] The second section 20 includes a second cavity 201 , a shaft cylinder 202 axially disposed in the second cavity 201 , a helical blade 203 wound around the out...

Embodiment 2

[0058] This embodiment provides a method for integrated crushing and landfilling of plastic waste. When implementing the method, the landfill pit 70 is dug in advance, and the geotextile 80 is suspended and fixed in the landfill pit 70 (see Figure 8 ), then follow these steps:

[0059] In the first step, the plastic waste is crushed by using the plastic waste crushing device described in Example 1;

[0060] In the second step, the plastic waste after the first step is crushed is introduced into the waste conveying pipeline 60 (see figure 1 );

[0061] In the third step, feed running water into the garbage delivery pipeline 60, flush the plastic garbage into the pre-dug garbage landfill pit 70, and make the garbage and running water drop to the top of the geotextile 80 (see figure 1 and Figure 8 );

[0062] The 4th step, treat that the tap water on the geotextile 80 drips to the bottom of the landfill pit 70 and is drained away by the drainage pipe 90 at the bottom of the...

Embodiment 3

[0067] Based on Embodiment 1 and Embodiment 2, this embodiment provides a plastic waste disposal system, which includes a crushing device, a deflector 50 , a waste conveying pipeline 60 , a waste landfill pit 70 and a geotextile 80 .

[0068] The crushing device includes a first section 10, a second section 20, a third section 30, and a fourth section 40 in which the shells are connected in sequence; the first section 10 includes a feeding channel 101 and a first cavity 102, so The feed channel 101 is positioned above the first cavity 102 and is inclined. The top of the feed channel 101 has a feed port 1011. A squeeze roller 103 for extruding plastic is installed in the feed channel 101. The squeeze roll 103 A magnet is arranged on it to absorb ferromagnetic substances. The first cavity 102 is provided with a coarse crushing roller 104 and a fine crushing roller 105 successively according to the moving direction of the material; the second section 20 includes the second cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com