Method for processing nanometer blind hole on surface of single silk through femtosecond laser

A femtosecond laser and surface processing technology, applied in the field of femtosecond laser applications, can solve the problems of natural silk micro-nano processing, small size and mechanical properties, and achieve high processing precision, simple process and good flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

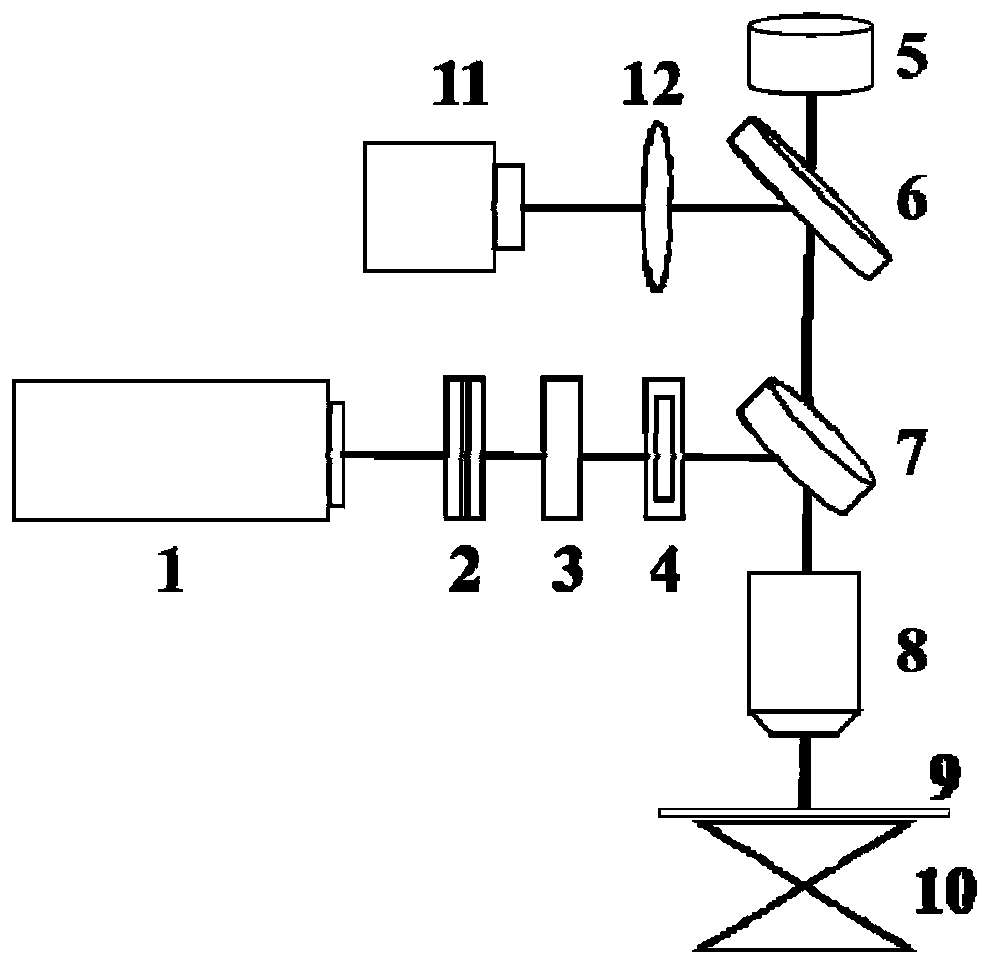

Embodiment 1

[0051] Adjust the neutral density attenuator 3, set the single pulse energy to 48.7nJ (4.34J / cm 2 , 1.13F th ); set the lens or microscope objective lens 8 as a 50× long working distance plan semi-apochromat lens (NA=0.5); through the electronically controlled shutter 4, control the number N of pulse sequences irradiated onto the silk 9 to be 350. Independent elliptical blind holes with a minor axis length of 74 nm were prepared on the silk 9 .

Embodiment 2

[0053] Adjust the neutral density attenuator 3, set the single pulse energy to 43.1nJ (3.84J / cm 2 , 1.07F th ); set the lens or microscope objective lens 8 to be a 50× long working distance plan semi-apochromat lens (NA=0.5); through the electronically controlled shutter 4, control the number N of pulse sequences irradiated onto the silk 9 to be 450. Independent elliptical blind holes with a minor axis length of 22 nm were prepared on the silk 9 .

Embodiment 3

[0055] Adjust the neutral density attenuator 3, set the single pulse energy to 40.1nJ (3.58J / cm 2 , 1.06F th ); set the lens or microscope objective lens 8 to be a 50× long working distance plan semi-apochromat lens (NA=0.5); through the electronically controlled shutter 4, control the number N of pulse sequences irradiated onto the silk 9 to be 650. Independent elliptical blind holes with a minor axis length of 66 nm were prepared on the silk 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com