Copper foil cutting machine

A cutting machine and copper foil technology, applied in metal processing, winding strips, thin material processing, etc., can solve problems such as copper foil damage, jamming, copper foil feeding problems, etc., to reduce quantity and reduce precision Requirements and eliminate stuck effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] Here, a preferred embodiment is used to illustrate the copper foil flattening mechanism 3 in the technical solution and a preferred copper foil cutting machine to which it can be applied.

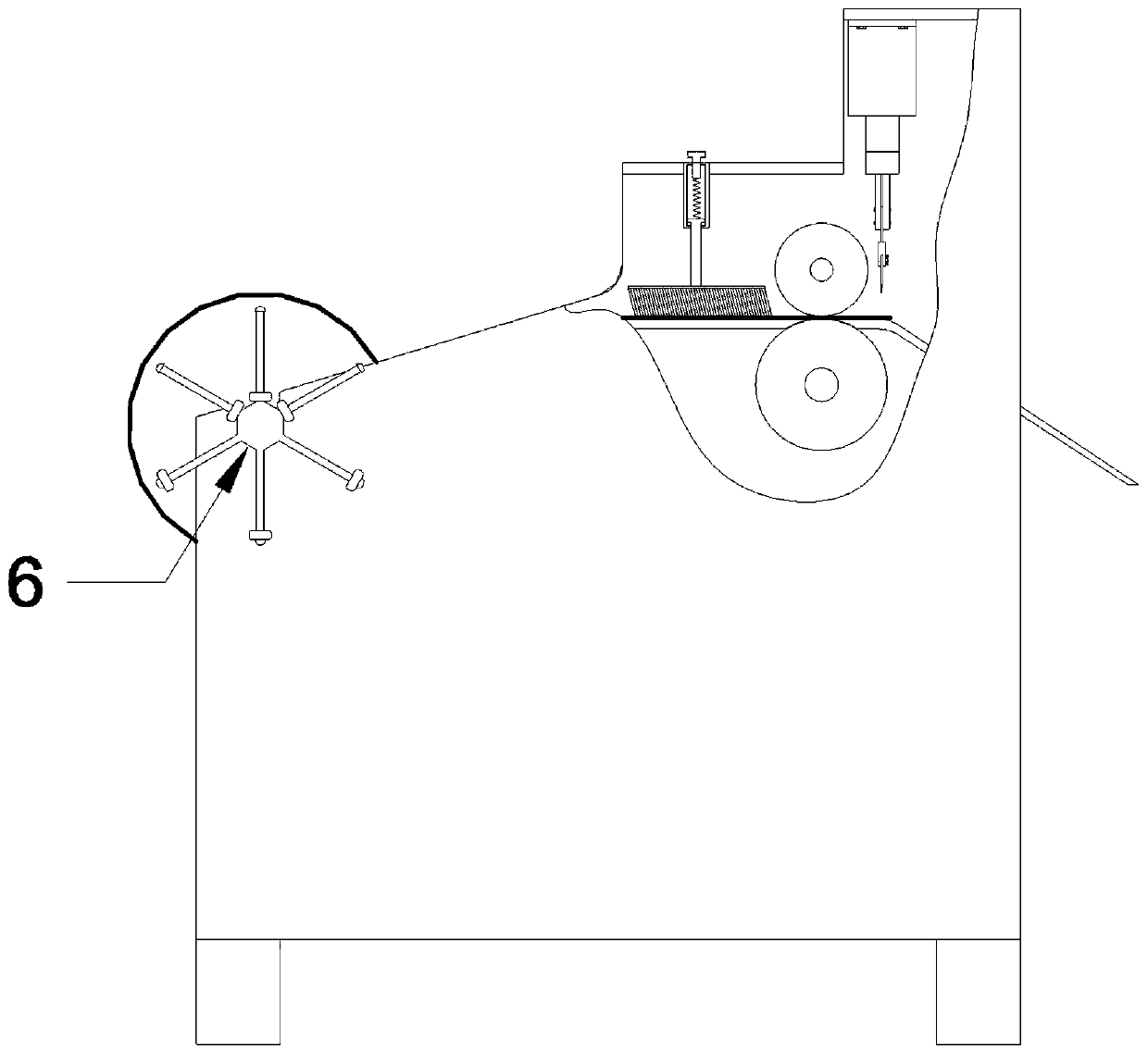

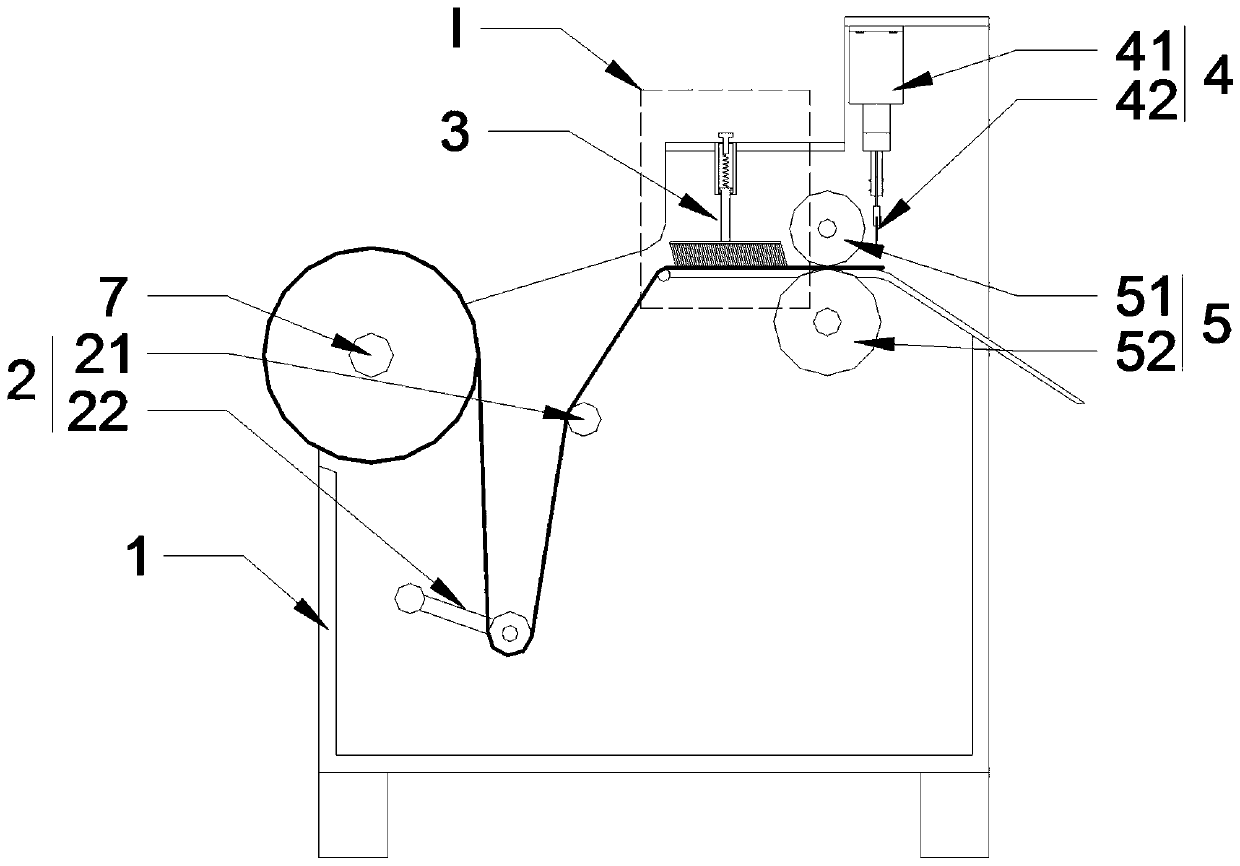

[0039] Similar to common copper foil cutting machines, the copper foil cutting machine in this embodiment includes a frame 1 for installing various components. The frame 1 can be a steel frame structure, which is welded to form a frame structure, and an installation location is reserved according to the arrangement of other components. Such as figure 1As shown, the frame 1 adopts a box structure, which is welded by 1-3mm steel plates to form the shape shown in the figure, so as to improve the integrity and aesthetics of the entire cutting machine; at the same time, because the side adopts a closed structure, it can also Improve the safety performance of the cutting machine. The tail of the frame 1 is in the shape of two steps rising in sequence, and a cutting mechanism 4 with a dow...

Embodiment 2

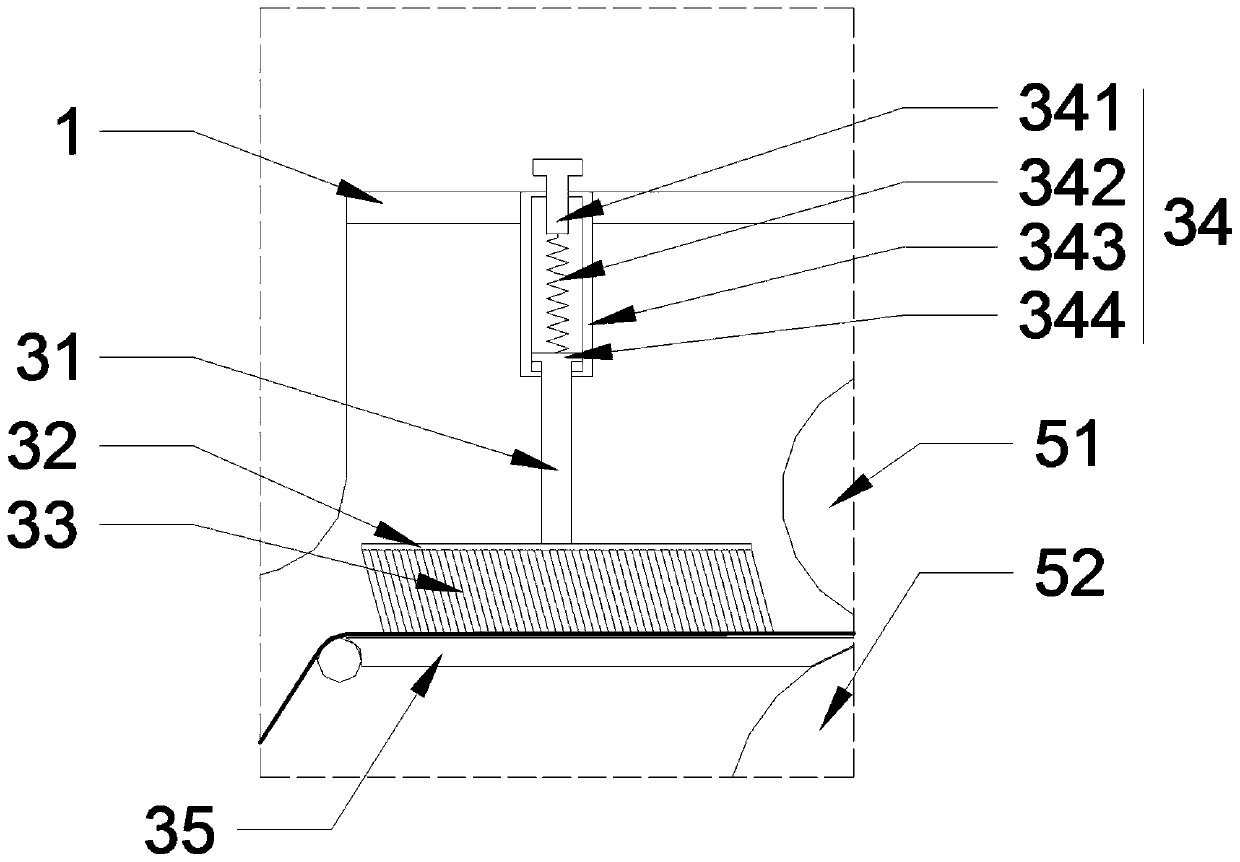

[0060] Since the copper foil has multiple thickness specifications, and the distance between the flattening mechanism and the feeding plate 35 in Embodiment 1 is fixed, the pressures that copper foils of different thicknesses are subjected to under the flattening mechanism are different, and the final flattening effect obtained by it is different. Effects also vary. Therefore, based on Embodiment 1, this embodiment provides a flattening mechanism with adjustable pressure generated by soft contact with the copper foil or the feeding plate 35 .

[0061]The difference between this flattening mechanism and the flattening mechanism in Embodiment 1 is that the fixed rod 31 of the flattened mechanism in Embodiment 1 is directly fixedly connected with the frame 1, while in the flattened mechanism in this embodiment, the fixed rod 31 is fixedly connected with the frame 1 through a piston structure 34 with adjustable damping size. The specific structure of a preferred solution of this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com