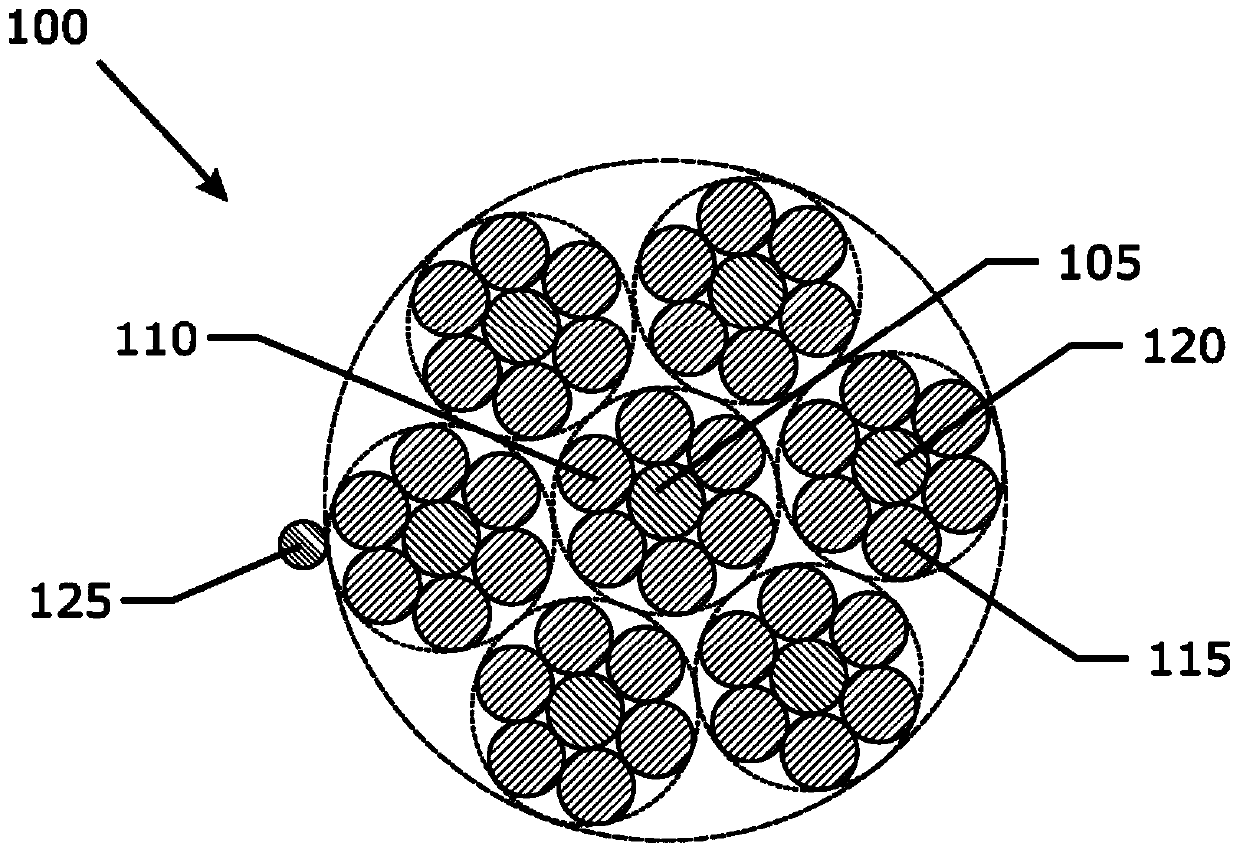

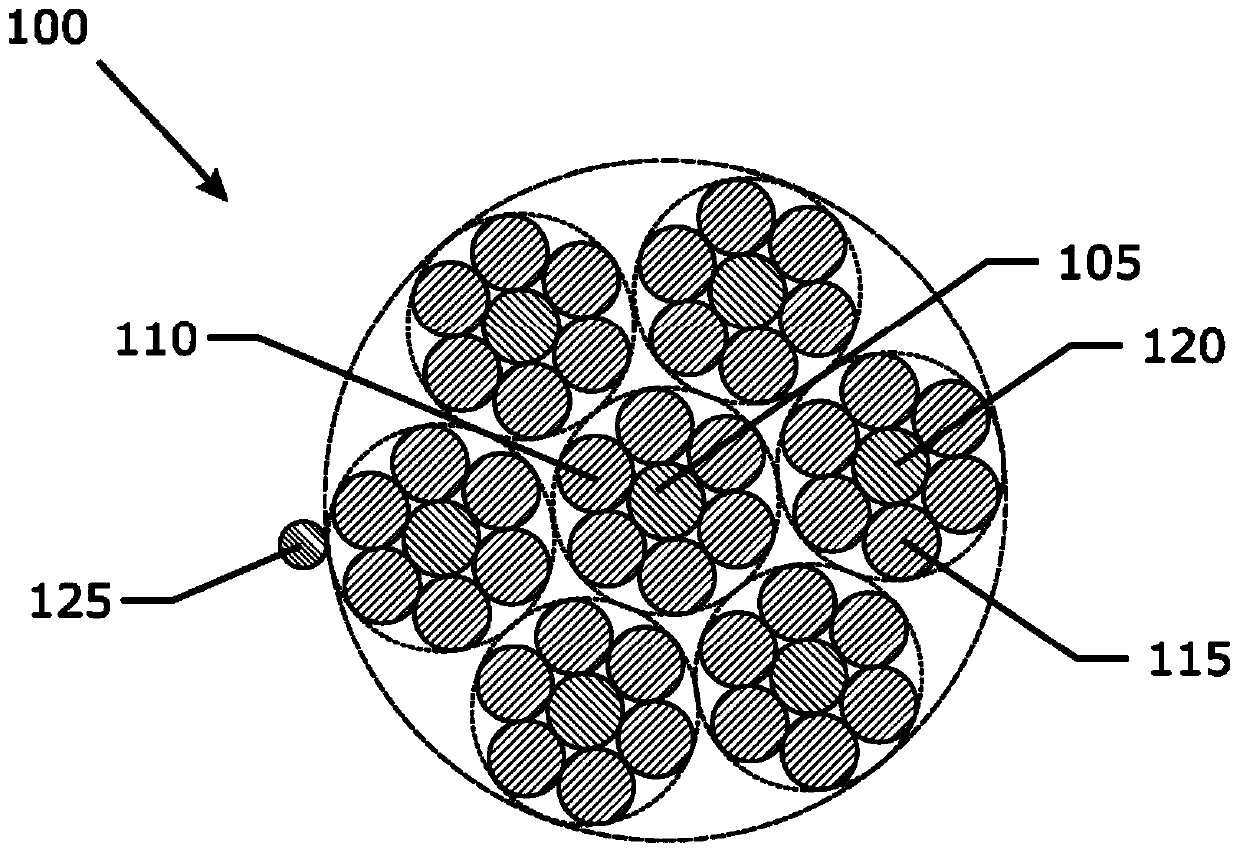

Steel cord

A technology of steel cord and monofilament, applied in the field of steel cord, can solve the problems of infiltration, corrosion, corrosion of steel cord, etc., and achieve the effect of good quality and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

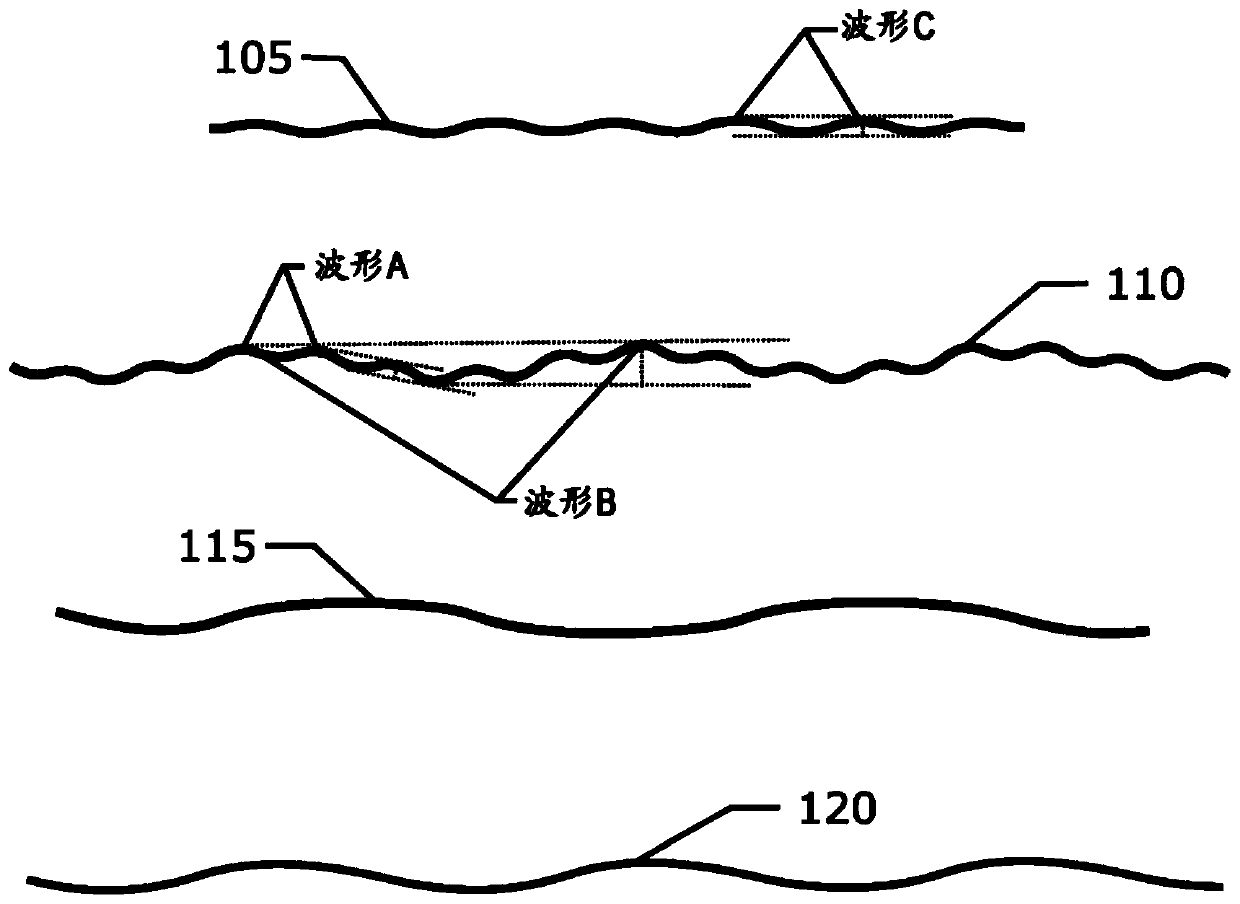

[0025] Steel monofilaments for steel cords are made from wire rods.

[0026] first by mechanical descaling and / or by 2 SO 4 Or chemical pickling in HCl solution to clean the wire rod to remove the oxides present on the surface. The rods are then rinsed in water and dried. The dried wire rod is then subjected to a first series of dry drawing operations to reduce the diameter to a first intermediate diameter.

[0027] At this first intermediate diameter, for example, at about 3.0 mm to 3.5 mm, the dry drawn wire is subjected to a first intermediate heat treatment known as plumbing. Leading means first austenitizing to a temperature of about 1000°C, followed by transformation from austenite to pearlite at a temperature of about 600°C to 650°C. The wire is then ready for further mechanical deformation.

[0028] Then, in a second step of the diameter reducing step, the wire is further dry drawn from the first intermediate diameter to a second intermediate diameter. The second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com