car shock absorber piston rod

A technology of automobile shock absorber and piston rod, which is applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc., can solve the problem that the surface hardness and smoothness are inversely proportional, so as to improve the surface hardness and smoothness and reduce the weight , to ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

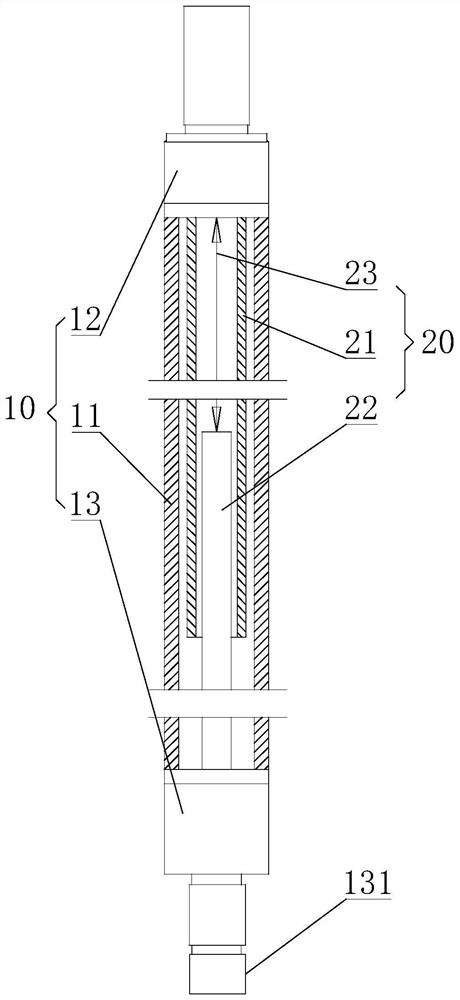

[0018] Examples, see figure 1 Shown: the automobile shock absorber piston rod, including the rod body 10. The upper end of the rod body 10 is fixedly connected with a piston, and the lower end is provided with a bracket thread 131 .

[0019] Further speaking:

[0020] The rod body 10 includes an intermediate tube 11 located in the middle, an upper connector 12 whose lower end is connected to the upper end of the intermediate tube 11 , and a lower connector 13 whose upper end is connected to the lower end of the intermediate tube 11 . The piston is fixed on the upper end of the upper connecting member 12 , and the bracket thread 131 is located on the lower outer surface of the lower connecting member 13 . That is to say, the middle part of the rod body 10 is a hollow structure.

[0021] The intermediate pipe 11 is prepared by a finish-rolled hollow steel pipe, and the upper connector 12 and the lower connector 13 are connected to the intermediate pipe 11 by friction welding....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com