Silicon-based micro gas chromatography column and preparation method thereof

A micro-gas chromatography, silicon-based technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of low surface area of micro-gas chromatography column, achieve the effect of increasing column capacity and increasing surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Such as Figure 1 ~ Figure 4 As shown, the present embodiment provides a kind of preparation method of silicon-based micro gas chromatography column, and described preparation method comprises steps:

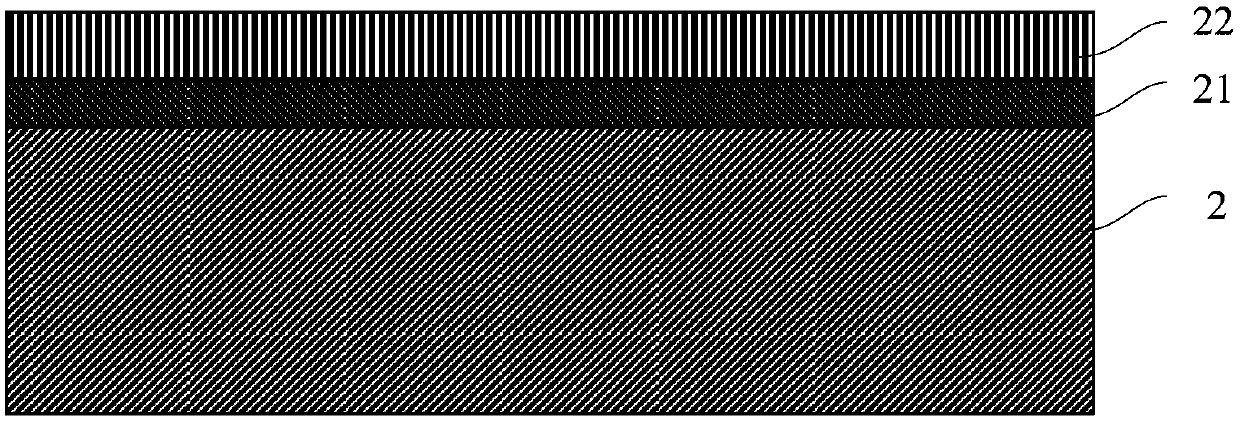

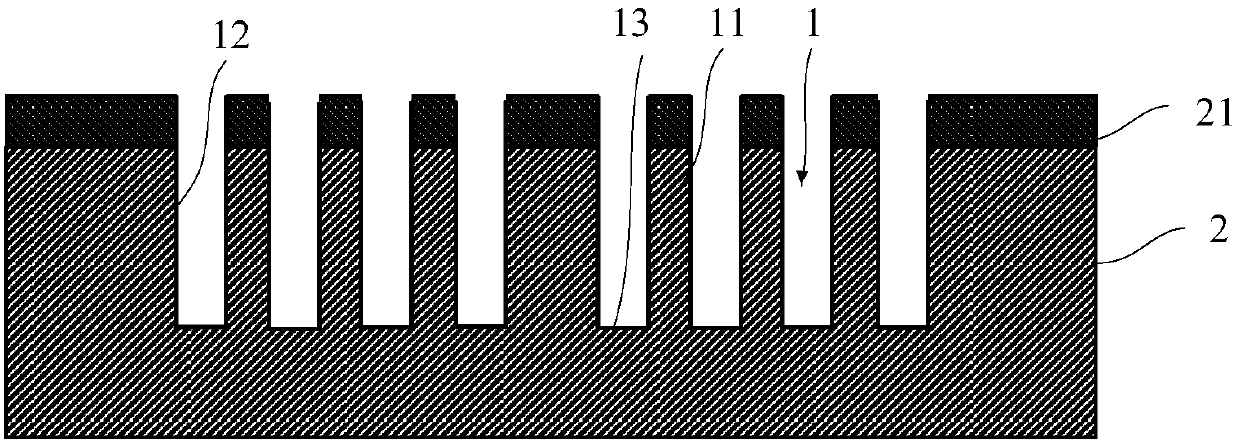

[0051] Such as Figure 1 ~ Figure 2 As shown, step 1) is first carried out, a silicon substrate 2 is provided, a silicon nitride film 21 is grown on the silicon substrate 2, and photoresist 22 is spin-coated, and silicon nitride is formed by photolithography-etching process and the mask pattern of photoresist 22, then adopt DRIE process to make microchannel 1 in described silicon substrate 2, then remove described photoresist 22, and described microchannel 1 can be curved back and forth extension, so The microchannel 1 includes a bottom 13 and sidewalls 12 .

[0052] As an example, the microchannel 1 also has one or both of a plurality of channel units and a plurality of micropillar 11 arrays.

[0053]As an example, step 1) further includes the step of fabricating micro...

Embodiment 2

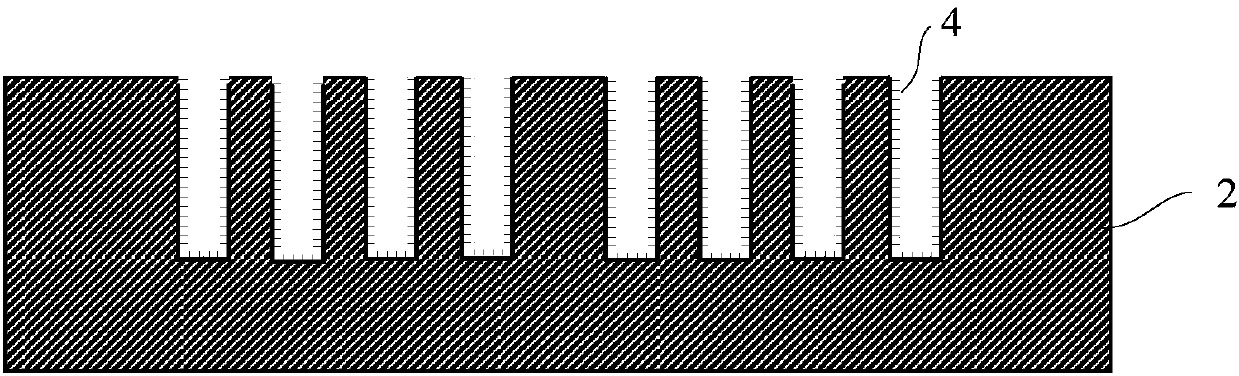

[0078] Such as Figure 1 ~ Figure 3 and Figure 5 ~ Figure 6 As shown, this embodiment provides a method for preparing a silicon-based micro-gas chromatographic column, the basic steps of which are as in Example 1, wherein the difference from Example 1 is that the package cover includes a silicon cover 5, A silicon nanowire forest 4 is prepared on the silicon cover plate 5 in a region corresponding to the microchannel 1 , and the silicon cover plate 5 is bonded to the silicon substrate 2 through a silicon-silicon bonding process. For example, a patterned silicon nitride mask layer is formed on the surface of the silicon cover plate 5, and then prepared on the surface of the silicon cover plate 5 corresponding to the microchannel 1 by the method in step 2). The silicon nanowire forest 4 is finally bonded to the silicon cover plate 5 and the silicon substrate 2 through a silicon-silicon bonding process.

[0079] Such as Figure 6 As shown, this embodiment also provides a sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com